Which factories are suitable for custom building solutions?

1. Modular flexible factory (suitable for discrete manufacturing such as electronics and automotive parts)

Advantages of modular structure:

- Using standardized prefabricated modules, a single module can achieve a flexible combination of 1,000-5,000 square meters (equivalent to the free splicing of 20 standard basketball courts), breaking the fixed partition restrictions of traditional factories.

- The modular design increases space reorganization efficiency by 30%-50%, and the production line layout can be quickly reconstructed according to the production process.

Construction efficiency:

- The factory prefabrication rate is over 90%, and the on-site assembly period is shortened by 50% compared with the traditional mode. The main structure of the 50,000 m2 factory building can be completed within 90 days.

- The modular interface supports "production and expansion at the same time", and the connection between new factories can be completed simultaneously during production without affecting normal operations.

Function expansion capability:

- The single-layer module has a load-bearing capacity of 5t/㎡, which can meet the installation requirements of heavy equipment such as precision machine tools and automated production lines.

- The intelligent ceiling system integrates logistics tracks and energy pipelines, supporting the rapid deployment of AGV robots and intelligent warehousing equipment.

Modeling and space design:

- The modular structure can achieve a variety of shapes (such as L-shaped, U-shaped, or circular layout) through a staggered combination of units, optimizing lighting and process flow.

- Case: A new energy vehicle battery factory adopted a modular design, shortening the logistics route by 40% and increasing production capacity by 25%.

Cost reference

Cost reference: The unit cost is about $400-600 USD/㎡. The comprehensive cost in the scenario of multi-variety and small batch production is 20% lower than the traditional solution.

2. Large-span intelligent factory (applicable to aerospace and heavy machinery manufacturing)

Space Technology:

- The spatial truss technology is used to realize a column-free production space, with the largest single span reaching 80 meters (equivalent to 11 standard basketball courts connected horizontally).

- The truss structure uses Q355B high-strength steel, with a material strength utilization rate of 95%, which is 40% lighter than traditional concrete structures.

Intelligent integration features:

- Equipped with a BIM digital management platform that integrates equipment monitoring, energy management, and production scheduling systems, equipment operation and maintenance efficiency is increased by 30%, and energy consumption is reduced by 15%.

- The roof can be equipped with a BIPV system, with annual power generation covering 30% of the factory electricity consumption, meeting green factory standards.

Disaster resistance and safety design:

Earthquake resistance reaches level 8, wind resistance level 12, equipped with full-process fire monitoring and emergency evacuation system, and passed GB 50011-2010 earthquake resistance testing and ISO 45001 safety management system certification.

Cost reference: The unit cost is $550-750 USD/㎡, suitable for high-end manufacturing scenarios with ultra-large working spaces.

3. Multi-storey industrial complex (suitable for precision manufacturing, R&D, and production integration)

Vertical Space Integration:

- The main construction period of buildings below 6 floors only takes 75 days, which is 180 days shorter than traditional concrete structures. It integrates production factors, laboratories, storage centers, and logistics channels.

Intelligent operation system:

- Equipped with facial recognition access control, material tracking system, and intelligent lighting control, traffic efficiency is improved by 40%, and manual management costs are reduced by 25%.

- A three-dimensional logistics transportation system is used between floors, increasing cargo turnover efficiency by 50%.

Flexible transformation capabilities:

- The internal partition walls are made of prefabricated aluminum alloy frames + replaceable finishes, which support the adjustment of floor functional zoning within 48 hours.

- Case: An electronic component factory used this solution to complete the transformation of its production lines from consumer electronics to automotive electronics within three months.

Cost reference: unit cost $380-520 USD/㎡, suitable for multifunctional integrated modern industrial parks.

Why do global manufacturing giants prefer customized factory building solutions?

1. Rapid construction to seize market opportunities

- The integrated "design-prefabrication-assembly" model is adopted to shorten the traditional construction period by more than 60%. Taking a 30,000 square meter factory building as an example, the customized solution can complete the main structure construction within 60 days, which is 120 days shorter than the traditional concrete solution, allowing the production line to be put into production 4 months ahead of schedule. Calculated based on an average daily output value of 1 million yuan, it can generate an additional 120 million yuan in revenue.

- Modular prefabricated components are processed with high precision in the factory, and on-site construction only requires assembly, reducing the impact of weather and human factors.

- Case: An automobile parts factory was able to complete construction on time during the rainy season, while competitors who adopted traditional solutions lost orders due to construction delays.

2. Resilience in dealing with uncertainty: Embracing manufacturing change

- Parametric design allows for expansion: modules can be added or removed as needed, and the production line layout can be quickly reorganized through a flexible partition system (adjustment time is reduced from 30 days to 3 days).

- Case: During the chip shortage crisis in 2022, a leading foundry won emergency orders worth hundreds of millions of yuan due to its ability to reorganize its production lines to produce automotive chips within 72 hours.

3. Green is not only a responsibility, but also a competitive advantage

- Sustainability advantages: Recyclable materials account for more than 85%, on-site construction waste is reduced by 90%, and the carbon footprint over the entire life cycle is about 60% lower than that of traditional factories.

- Energy saving benefits: The roof photovoltaic and ground source heat pump system has a comprehensive energy saving rate of 35%. Case: With customized solutions and LEED Gold certification, the "Green Source Food" factory saves 1.2 million yuan in energy expenses annually and obtains green subsidies from the local government.

- Asset reusability: Modular design allows more than 70% of the structure and equipment to be reused in future relocation or renovation. When a construction machinery company relocated, the modular disassembly and reconstruction solution saved 40 million yuan compared to demolition and reconstruction.

4.

Intelligence grows from the "roots": seamless connection with Industry 4.0

- IoT interfaces and pipeline channels are pre-buried during the design phase to support "plug and play" of sensors, AGVs, and digital twin platforms.

- Case: "Aoxiang Aviation" reduced unplanned downtime of key equipment by 80% and achieved preventive maintenance through the use of BIM models throughout the process; after a chemical company applied the intelligent energy management platform, its energy consumption per unit of output value decreased by 18%.

Typical scenario: How customized solutions take root

| Scene Type |

Technical features |

Cost reference |

| Automobile Intelligent Manufacturing Base |

80-meter-long truss column-free space, nested modular flexible production line, accommodating more than 500 robots |

$700-900 USD/㎡ |

| Electronic precision manufacturing factory |

Multi-layer steel structure complex, superimposed Class 1000 dust-free purification and ≤50nm micro-seismic control |

$650-850 USD/㎡ |

| Temporary emergency capacity |

Lightweight modules + quick assembly and disassembly system, 1000-3000㎡ production space can be built in 72 hours. |

A single module is about USD 150,000 |

| Industry 4.0 Lighthouse Factory |

Intelligent steel structure skeleton and digital twin are deeply bound together, and equipment OEE is increased by 25% |

$900-1200 USD/㎡ |

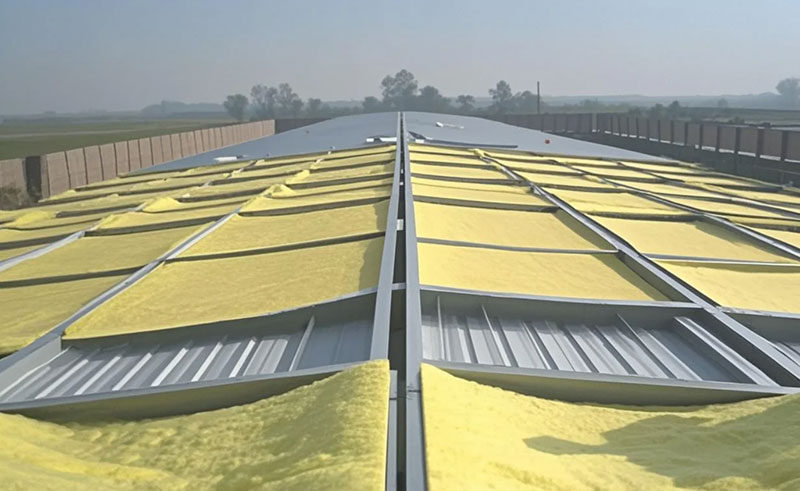

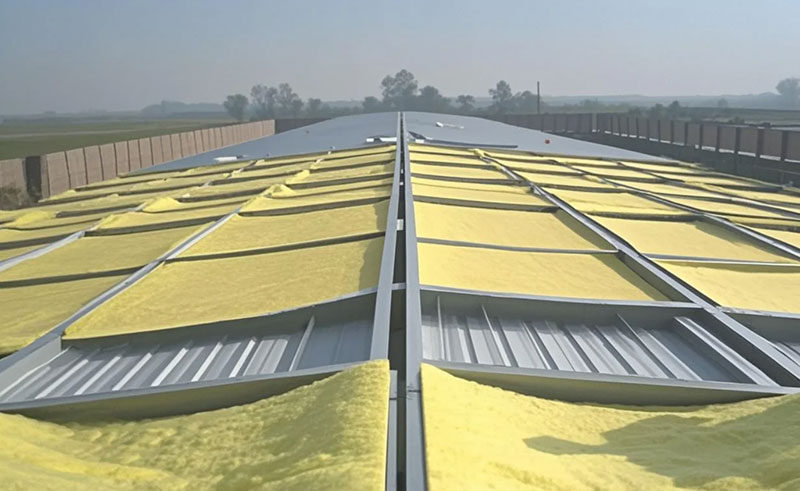

| Food and medicine clean fortress |

Stainless steel composite structure, strictly abides by the GMP/FDA system, reduces microbial risk by more than 90% |

$800-1000 USD/㎡ |

Custom vs. traditional: Hard-core data on value comparison

| Comparison Dimensions |

Customized factory construction solutions |

Traditional construction model |

| Spatial freedom |

80 meters of column-free space |

≤20m column grid (densely distributed columns) |

| 30,000㎡Construction period |

≈60 days for the main construction to be completed |

≈240 days (including maintenance) |

| Production line adjustment time |

The flexible partition wall was completed within 3 days. |

The wall demolition and reconstruction will take at least 15 days. |

| Carbon emissions |

≈1.5 tons CO₂/㎡ (60% reduction) |

≈3.8 tons CO₂/㎡ |

| Renovation cost |

Local module adjustment saves 60% |

Demolition and construction costs are high, and garbage piles up. |

| Intelligent foundation |

Native support, seamless integration |

Later-stage transformation is difficult, and the effect is discounted.d |

| 20-year full cycle cost |

35% lower on average |

Maintenance costs are rising year by year. |

Technical foundation: the hard power that supports customized factory solutions

1. Skeletal system - structure

- Frame: Q355B high-strength steel (345 MPa grade) is preferred, and the column distance is increased to 15 meters to reduce column obstruction; the long-span truss is optimized through finite element analysis and can withstand strong winds of 1.5kN/m².

- Foundation: Prestressed pipe piles + integral raft slab (bearing capacity ≥ 300 kPa), equipped with anti-pullout anchor system in typhoon area (resistant to level 12 wind, 32.7m/s).

2. Skin and nerves - enclosure and intelligence

- Smart "coat": double-layer steel plate + 100mm thick thermal insulation cotton composite roof, heat preservation in winter and heat insulation in summer; integrated photovoltaic panels (60% light transmittance), annual power generation = installed capacity × local sunshine peak × 0.8 efficiency factor (for example: 2000kW rooftop annual power generation ≈ 1.6 million kWh).

- Flexible "partition": light steel keel + quick-install panel, modular pre-installed water, electricity, and gas interfaces, partition walls can be adjusted within half an hour to improve the efficiency of production line reorganization.

- Digital "senses": The BIM operation and maintenance platform monitors structural deformation, equipment status, and environmental parameters in real time, and responds to abnormal alarms within 10 seconds.

3. Green Gene - Standards and Certification

3. Green Gene - Standards and Certification

- Energy consumption bottom line: Strictly abide by the national standard GB50189-2015, the wall and roof heat transfer coefficient K value ≤ 0.3 W/(m²・K).

- International "Green Card": Support LEED and BREEAM certification. Case: After a customer obtained LEED Silver certification, the factory rent was 20% higher than the surrounding area.

FAQ

Q:

"Will the customized factory meet the load-bearing requirements for our 100-ton stamping press?"

A: Don't worry! It uses Q355B and above high-strength steel and a 50-80 meter long-span column-free design. It is suitable for heavy machinery factories, aircraft engine factories, and integrated die-casting factories for new energy vehicles. The design load is generally ≥8 tons/㎡. Case: "Zhongqi Group" has made a reinforced design for the 100-ton press station. After mechanical simulation and static load test verification, it has been running stably for two years.

Q:

"Will maintenance costs become a bottomless pit in the long run?"

A: On the contrary, the customized factory design is highly maintainable:

- The annual maintenance fee for a medium-sized factory accounts for 4%-8% of the construction cost (e.g., a 50,000 m2 factory accounts for approximately RMB 300,000-600,000 per year). The maintenance fee in humid/coastal areas increases by 20%-40%.

- Adopting weather-resistant materials such as hot-dip galvanized steel and silane coating, the overhaul period is 5-8 years; damaged modules can be quickly replaced (saving 50% time), and the intelligent system supports "prevention before disease occurs". Case: The total maintenance cost of "Xinlian Electronics" for 20 years is 30% lower than that of traditional solutions.

Q:

"It's adequate for now, but how about future production expansion?"

A: "Scalability" is the core advantage:

- The first phase reserves module interfaces and pipeline channels. When expanding production, new modules can be connected like "building blocks" without interrupting production.

- Case: The second phase of "Xunchi" added 30% of its production capacity in just 30 days, while traditional expansion would take more than half a year.

- Standardized interfaces ensure rapid connection to the water, electricity, and gas networks. The "Extreme Logistics" sorting center once withstood the peak pressure 45 days before "Double Eleven" by adding new modules.

Q:

"Precision instruments are sensitive to vibration and noise – can you handle this?"

A: Acoustic vibration control solution:

- Sound insulation: The special composite wall (keel + double-layer board + sound-absorbing cotton) has a sound insulation of 55- 60 dB. The "silent compressor" project uses this to reduce the factory boundary noise to below the 55 decibel standard.

- Shock absorption: Springs + rubber shock-absorbing pads are used as the foundation of precision equipment, and micro-vibration control reaches 50 nanometers. The environmental vibration in the area of the "Jinghua Semiconductor" lithography machine is stable within 30 nanometers.

- Sound absorption: The tall space uses a professional sound-absorbing ceiling (sound absorption coefficient ≥ 0.8), and the "Power Test Center" reduces the roar of the factory from 110 decibels to 85 decibels.

Q:

"How long will it take to recoup the additional investment?"

A: Take a 30,000 square meter electronics factory as an example:

The initial investment of the customized solution is 15% higher than the traditional one, but:

- Started production 4 months ahead of schedule → earned an additional 80 million yuan in output value;

- 20% higher space utilization → saving the equivalent of 6,000 square meters of land;

- Energy consumption is reduced by 15% → annual electricity bill savings of 1.2 million;

- Flexible production with fast response → Annual profit increased by 5 million.

Comprehensive payback period: about 3.5 years (high value-added industries such as semiconductors and biomedicine can pay back in 2-3 years), traditional factories take 8-10 years.

Customized factories: more than just construction, it's about the future of manufacturing.

The competition of Industry 4.0 starts with infrastructure. The professional customized factory construction solutions from

XTD Steel Structure are building a future-oriented "super production platform" for global manufacturing companies with the core capabilities of "BIM forward design drives factory-based intelligent manufacturing and on-site precise assembly". From new energy vehicle intelligent manufacturing bases to semiconductor clean factories, from emergency production capacity fortresses to Industry 4.0 lighthouse factories, customized solutions are transforming "space" into production capacity advantages, cost advantage, and agility advantages.

Whether you are an industry giant planning a strategic layout or an innovative enterprise seeking a way out, customized factory construction solutions are willing to build an industrial space that truly adapts to your core competitiveness with modular smart bones, digital efficient block, and sustainable green genes.