China's dominance in this sector is no accident. With advanced factories, a skilled workforce, cost-effective production processes, and strict adherence to international quality standards, Chinese suppliers have earned a reputation for delivering large-scale projects faster and more cost-effectively than many of their global counterparts. As global demand for modern warehousing solutions continues to soar, more and more businesses are turning to Chinese manufacturers to meet their needs.

This article explores how China has taken a leading position in the prefabricated construction market, the advantages of choosing Chinese steel warehouses, and the future direction of this booming industry. Whether you're a logistics operator, an industrial investor, or simply interested in global construction trends, understanding China's role in warehouse manufacturing is crucial to navigating the future of supply chain infrastructure.

The rise of steel structure warehouses in modern logistics

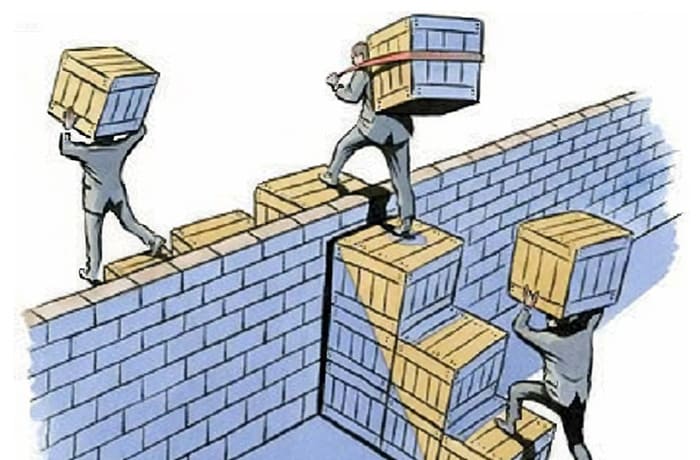

Steel warehouses have seen widespread global adoption in recent years as critical infrastructure in modern logistics and supply chain systems. The gradual transition from traditional brick-concrete and timber structures to steel structures has become a major trend in the warehousing industry. Especially amid the rapid growth of e-commerce, cross-border trade, and cold chain logistics, steel warehouses, with their efficiency, durability, flexibility, and scalability, have gradually replaced traditional warehouses, becoming a crucial pillar driving the upgrading of the logistics industry.

Why choose steel over traditional materials?

The selection of steel as the primary construction material for warehouses is not coincidental, but rather an inevitable outcome of market and technological evolution. First, steel possesses significantly higher strength than wood and concrete, enabling it to maintain structural stability under greater spans and heavier loads. Second, steel's excellent ductility and malleability allow modern fabrication techniques to shape it into complex components, meeting the customized requirements of diverse warehouse types. Additionally, steel structures feature short construction cycles and high prefabrication rates, significantly reducing project timelines and labor costs. These advantages make steel-framed warehouses not only economically competitive but also more adaptable to complex market demands.

Global Demand for Warehouse Solutions

The continuous expansion of global trade is presenting logistics systems with unprecedented challenges and opportunities. The rise of e-commerce, rapid growth of cross-border platforms, and increasing global trade in cold-chain food products are driving higher demands for warehousing. Large capacity, intelligence, and sustainability have gradually become the industry consensus. Steel structure warehouses, with their scalability, rapid construction, and low maintenance costs, are emerging as a core solution in global warehousing. Growing demand across markets in Europe, America, Asia-Pacific, the Middle East, and Africa is driving a sustained upward trend in the international market for steel structure warehouses.

Advancements in Prefabrication Technology

Prefabrication technology plays an indispensable role in the construction of steel structure warehouses. Through factory-based prefabrication, components are processed and inspected on high-precision production lines before being transported to the site for assembly. This approach not only shortens construction timelines but also significantly enhances quality consistency and safety. Prefabricated steel structure warehouses enable large-scale construction in a short time, making them particularly suitable for the rapid expansion of logistics centers, cross-border trade hubs, and large-scale manufacturing clusters. This trend is establishing prefabricated steel structures as synonymous with modern logistics infrastructure.

Competitive advantages of China's steel structure warehouse manufacturing

Amid the global surge in steel warehouse development, China has become a significant manufacturing power. With a well-developed industrial chain, robust production capacity, and continuously improving technological capabilities, Chinese steel warehouse manufacturing possesses unique competitive advantages in the international market.

Cost efficiency and economies of scale

One of the greatest advantages of Chinese steel warehouses lies in their ability to control costs. Large-scale production and centralized procurement of raw materials, combined with vast manufacturing capacity and economies of scale, enable Chinese factories to provide high-quality steel at lower prices. This advantage is particularly evident in international competition, especially in developing and emerging markets, where cost-effectiveness is a primary consideration for buyers.

Technological advancements in Chinese factories

Over the past few decades, China's steel warehouse manufacturing industry has not relied solely on low-cost competitiveness, but has also continuously advanced in processes and technology. The widespread use of CNC machining, laser cutting, 3D modeling, and BIM systems has enabled Chinese factories to achieve high-precision production and the rapid implementation of complex designs. Furthermore, automated and intelligent production lines reduce human error, improve production efficiency, and strengthen international customers' confidence in Chinese manufacturing.

Skilled Workforce and Streamlined Production Processes

Beyond advanced equipment, China's steel structure warehouse manufacturing benefits from a large pool of experienced engineers and skilled workers. They not only operate modern machinery proficiently but also adapt flexibly to complex engineering challenges. Combined with production processes refined over years—from design and fabrication to logistics—Chinese factories have established a comprehensive system of efficient, streamlined workflows. This enables rapid project delivery and strong responsiveness.

Design and engineering of steel structure warehouses in China

The value of steel warehouses lies not only in manufacturing costs but also in their design and engineering capabilities. Chinese manufacturers, leveraging their accumulated engineering experience and technological advantages, have developed a flexible and diverse design system.

Key Components of Prefabricated Steel Structure Warehouses

A complete steel structure warehouse primarily consists of steel columns, beams, purlins, wall panels, roof panels, and connecting nodes. Chinese manufacturers place strong emphasis on material selection and production processes to ensure these components meet both load-bearing requirements and long-term structural durability. All parts undergo strict quality inspections in the factory and can be efficiently assembled on-site, significantly accelerating construction.

Customization Flexibility

Another core advantage of Chinese steel structure warehouses lies in their customization capability. Clients often have diverse storage needs—for example, e-commerce centers require large-span column-free spaces, while cold storage facilities need thermal insulation design. Chinese manufacturers can adapt designs flexibly according to specific requirements, delivering solutions that comply with industry-specific standards. This adaptability offers substantial value to customers.

Compliance with International Standards

In the global market, compliance with relevant building standards is crucial for the adoption of warehouse systems. Chinese steel structure warehouse manufacturers have gradually accumulated extensive experience in international projects and are capable of producing products that meet European EN standards, American ASTM standards, and ISO certifications. This capability has not only facilitated access to international markets but also enhanced global recognition of Chinese steel structure warehouses.

Application of Chinese steel structure warehouses in different industries

Steel structure warehouses have a wide range of applications, providing customized solutions for sectors from e-commerce to agriculture.

E-commerce and Logistics Centers

With the rapid global expansion of e-commerce, demand for warehousing infrastructure continues to grow among e-commerce platforms and express delivery companies. Steel structure warehouses, characterized by their large spans, column-free spaces, and high load-bearing capacity, meet the deployment requirements for automated sorting systems and multi-tier shelving. For instance, in large cross-border e-commerce hubs, Steel structure warehouses not only handle daily throughputs of hundreds of thousands of goods but also enable rapid internal process adjustments through flexible layouts to accommodate peak shopping seasons and promotional surges. Simultaneously, the expandability of steel structures allows logistics centers to scale operations effortlessly with business growth, avoiding operational cost increases caused by limitations of traditional structures.

Cold Storage and Food Warehousing

The rise of cold chain logistics has elevated Steel structure warehouses to a pivotal role in storing food, pharmaceuticals, and bioproducts. These facilities typically require sustained low-temperature or constant-temperature environments. Steel structures, combined with insulated wall panels and roof insulation systems, effectively minimize energy loss, maintaining stable storage conditions. Furthermore, the airtightness and load-bearing capacity of steel warehouses meet the operational requirements of refrigeration equipment, ensuring efficient cooling system performance. Compared to traditional warehouses, Steel structure cold storage facilities offer faster construction speeds and superior energy management capabilities—critical advantages for temperature-sensitive industries like food and pharmaceuticals.

Industrial and Manufacturing Warehousing

Manufacturing requires storage for large volumes of raw materials and semi-finished goods. Steel structure warehouses, with their high load-bearing capacity and scalability, are a common choice in industrial parks. The industrial production chain's demand for warehousing facilities primarily focuses on storing raw materials and semi-finished goods, along with providing logistics support for production lines. Steel structure warehouses leverage their high load-bearing capacity and spacious design to effectively accommodate large machinery, metal materials, and bulk components. Particularly in heavy industries like automotive, machinery manufacturing, and shipbuilding, the durability and safety of Steel structure warehouses provide crucial safeguards for enterprises to mitigate operational risks. They not only offer stable storage environments but also integrate with intelligent logistics systems to achieve efficient, integrated production and warehousing operations.

Agricultural and Rural Applications

In agriculture, Steel structure warehouses are gradually replacing traditional brick-and-wood grain storage facilities, finding widespread use for storing grain, feed, and agricultural machinery. Their relatively reasonable cost and short construction cycles make them particularly suitable for centralized construction needs in rural areas. Additionally, Steel structure warehouses can adjust ventilation and humidity control systems according to different crop characteristics, thereby reducing grain mold and loss. Furthermore, these warehouses can serve as auxiliary facilities for livestock farming, providing durable and expandable space that supports the scaled and intensive development of modern agriculture, injecting new momentum into agricultural modernization.

Comparison of Chinese Steel Structure Warehouses with other global suppliers

In the global market, Chinese steel warehouses stand out from competitors in Europe, the US, and Japan.

Price Competitiveness

Chinese steel structure warehouse manufacturers demonstrate a significant competitive advantage in pricing. Benefiting from centralized procurement of upstream steel resources and a well-established supply chain system, Chinese factories can substantially reduce raw material costs. Meanwhile, economies of scale achieved through mass production further drive down the average cost per unit, making it considerably lower than comparable products from Europe, the United States, and Japan. This price advantage not only helps Chinese companies rapidly capture market share in emerging economies but also encourages clients from many developed countries to outsource part of their warehouse construction to Chinese manufacturers. Cost-effectiveness has become a key factor attracting global customers.

Quality and Durability Standards

Although "Made in China" was once questioned for inconsistent quality, Chinese steel structure warehouses have made substantial progress in craftsmanship and standards. A growing number of manufacturers have obtained international certifications such as ISO, ASTM, and EN, ensuring compliance with high global standards. Moreover, the adoption of automated production lines and BIM technology has significantly improved precision and durability. Through rigorous testing and evaluation, Chinese steel structure warehouses now meet or even exceed international counterparts in wind resistance, seismic performance, and fire safety, providing customers with reliable long-term usability.

Delivery and Supply Chain Efficiency

Chinese steel structure warehouse manufacturers excel not only in production but also in delivery and supply chain management. Leveraging a well-developed port infrastructure and global logistics network, Chinese factories can efficiently ship large-scale components to destinations worldwide. Additionally, during project execution, manufacturers optimize assembly plans in advance based on the installation conditions in the client's country, reducing on-site construction difficulties and timelines. Compared to countries with slower supply chains, Chinese companies often complete deliveries in a shorter time, enabling clients to bring warehouse facilities into operation more quickly and enhancing their market responsiveness.

The role of sustainability in China's steel structure warehouse production

Sustainable development has become a key theme in the global construction industry, and Chinese steel warehouse manufacturing is actively responding to this trend.

Green Building Standards and Certifications

An increasing number of Chinese steel warehouse projects are applying for and obtaining international green building certifications such as LEED and BREEAM. This not only demonstrates their environmental friendliness but also enhances their competitiveness in the international market.

Energy-Saving Warehousing Design

Energy-saving concepts are incorporated into the design of steel warehouses. For example, natural lighting systems, rooftop solar installations, and the use of high-efficiency insulation materials can effectively reduce operational energy consumption.

Recycling and Environmentally Friendly Steel Use

Steel itself is a highly recyclable material. Chinese manufacturers are actively promoting recycling and gradually adopting low-carbon steel and environmentally friendly coating materials to reduce the carbon footprint of the production process.

Global Market Challenges and Concerns

Despite significant success in the global steel structure warehouse market, Chinese steel structure warehouse exports still face challenges and concerns.

Trade Policies and Tariffs

Amidst a complex international trade environment, it continues to face policy challenges. Tariff friction between China and the United States, as well as trade barriers imposed by some European countries on steel products, have directly impacted export costs and profit margins. This has forced some customers to consider additional tariffs and compliance costs when purchasing, impacting the price advantage of Chinese steel structure warehouses. Furthermore, the rise of international trade protectionism could also bring market uncertainty, forcing Chinese manufacturers to strike a balance between risk avoidance and exploring diversified markets.

Logistics and Transportation Costs

Steel structure warehouses often involve large-span and heavy components, which can be significantly affected by transportation distance, port facilities, and transfer efficiency during cross-border shipping. Rising logistics costs may partially offset the price advantages of Chinese manufacturing. Additionally, frequent fluctuations in international freight rates can increase financial pressure on enterprises. To address these challenges, Chinese manufacturers are increasingly focusing on collaboration with logistics partners. By optimizing container designs, adopting modular transportation, and improving supply chain coordination, they aim to reduce additional burdens in the shipping process and ensure delivery efficiency.

Perception of "Made in China" Quality

Although Chinese steel structure warehouses have made remarkable improvements in quality, a certain degree of brand perception bias persists in some international markets. Some customers remain concerned that "Made in China" implies low cost at the expense of quality, which somewhat limits Chinese companies’ access to high-end markets. To improve this image, Chinese manufacturers need to consistently showcase successful projects, obtain third-party certifications, and strengthen collaborations with international brands. Enhancing after-sales service and providing long-term maintenance commitments will also help shift market perception, gradually aligning "Made in China" with high quality and reliability.

Case Study: Globally Successful Chinese Steel Structure Warehouse Project

Chinese steel warehouse manufacturers have successfully implemented projects in multiple regions.

Expansion Projects in the Asia-Pacific Region

In Southeast Asian countries, China-made steel structure warehouses are widely used in e-commerce distribution centers, effectively addressing logistical bottlenecks.

Warehousing Solutions in Africa and the Middle East

In African and Middle Eastern markets, Chinese steel structure warehouses provide efficient storage support for local businesses, leveraging advantages such as low cost and rapid construction.

Integration into Western Supply Chains

Chinese steel structure warehouses are gradually entering European and American supply chains, participating in the development of global storage systems for retail giants and multinational manufacturers.

Future Outlook of China's Steel Structure Warehouse Industry

The future development of China's steel structure warehouse industry will be increasingly intelligent, green, and international.

AI and IoT-Based Smart Warehousing

Smart warehousing will be a key focus in the future. Through AI and IoT systems, warehouses will achieve automated monitoring, intelligent scheduling, and predictive maintenance, further enhancing operational efficiency.

Global Partnerships and Joint Ventures

Chinese companies will strengthen cooperation with international partners and establish joint ventures to jointly develop new markets, facilitating better integration into global supply chains.

Projections for the Next Decade

Over the next ten years, the export of Chinese steel structure warehouses will continue to grow, particularly in developing markets. Meanwhile, their share in high-end markets will gradually expand, solidifying China's elevated role in global warehouse manufacturing.

Choose the right Chinese steel structure warehouse supplier

Among the many suppliers, buyers need to carefully select to ensure the quality and smooth delivery of the project.

The key factors to consider (cost, delivery time, standards) are:

- Cost structure transparency

- Reliability of delivery time

- Comply with international building standards

Certification and Track Record Verification

Clients should prioritize whether suppliers possess international certifications and can demonstrate a history of successful projects. These serve as critical indicators of their capabilities and credibility.

How to Avoid Common Pitfalls in Supplier Selection

Buyers should avoid focusing solely on low prices while overlooking long-term maintenance costs. It is essential to validate a supplier's actual competence through on-site visits and third-party inspections.

Conclusion

Chinese steel warehouses have become a vital pillar of the global logistics and warehousing industry. Leveraging cost advantages, technological innovation, and sustainable development efforts, Chinese companies are demonstrating increasing competitiveness in the international market. From Asia Pacific to Africa, from the Middle East to Europe and the United States, Chinese steel warehouses are constantly reshaping the global perception of "Made in China." In the future, with the continued advancement of intelligent, green, and international development, prefabricated steel warehouses will continue to serve as the backbone of modern logistics, supporting the efficient operation and sustainable development of the global supply chain.