The good news? You can achieve cost savings and still deliver a high-quality project. This blog post shares practical tips to budget smartly for steel structure projects. We'll draw lessons from Qatar's iconic Lusail Stadium and Stadium 974 to show how real-world projects keep costs low.

Ready to build smarter? Let's dive in.

Define Your Project Scope Clearly

Every steel structure project starts with a clear plan. You need to know exactly what your project requires. This includes size, load capacity, and design details. A well-defined scope prevents expensive mistakes down the line.

For example, Qatar's Lusail Stadium, built for the

2022 FIFA World Cup, needed an 80,000-seat capacity with a complex steel roof. Planners outlined precise steel specifications upfront. This clarity effectively reduces material waste and ensures cost savings. Without a clear scope, you risk costly redesigns or delays.

Tip: Write a detailed project brief. Include dimensions, weight requirements, and aesthetic goals. Share this with your steel supplier early to align expectations.

Lusail Stadium's clear scope ensured cost-saving steel use for its massive structure.

Embrace Modular Steel Designs

Modular steel designs are a game-changer for cost savings. These pre-engineered components are manufactured off-site and assembled like building blocks. They reduce labor time, cut material waste, and speed up construction.

Qatar's Stadium 974 is a perfect example. This 40,000-seat venue used modular steel to create a fully demountable structure. The design enabled the stadium to achieve significant cost savings and was completed in record time. Modular designs also offer flexibility for future expansions or modifications.

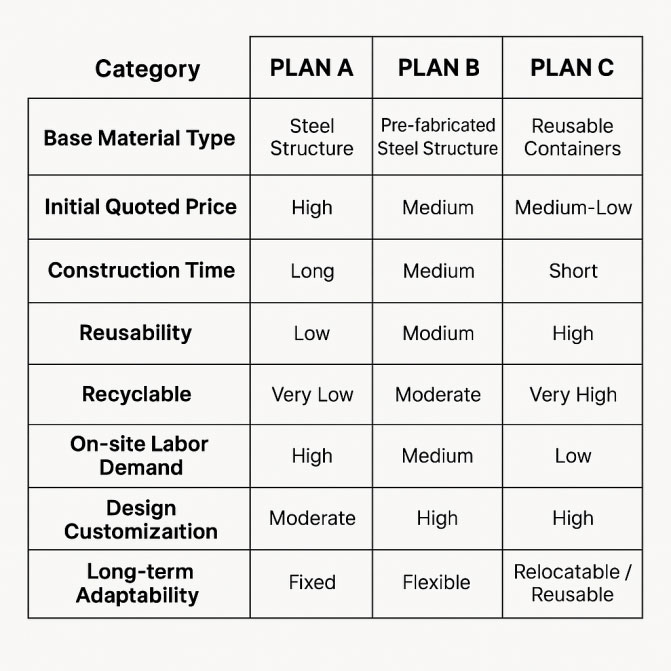

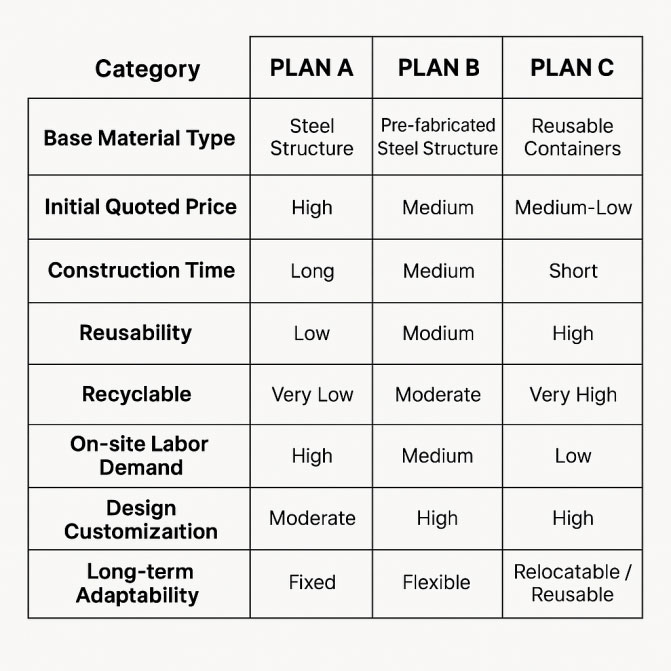

Modular steel structures have a variety of design options, including rigid frame structures, space frame structures, and space truss structures, etc. As an experienced manufacturer in this industry, we understand that different structural designs will affect the cost.

XTD Steel Structure successfully helped our client save millions of investment while satisfying their needs. In this case, our client's original design was made by a truss structure, which is one of the most common choices for factory buildings, after we understood their needs with specific requirements. We proposed using space frame structures instead of the current design, as a result, we helped our client save a hundred tons of material and significantly reduce the cost.

Tip: Ask your steel supplier about modular options. Request a cost comparison between modular and custom designs to see the savings.

Modular steel designs save time and money with efficient assembly.

Select Cost-Effective Steel Grades

Choosing the right steel grade balances cost and performance. High-strength steel, for instance, lets you use less material while maintaining durability. This reduces steel structure project costs significantly.

However, the steel must meet safety and quality standards. Lusail Stadium's massive roof relied on high-strength steel to support heavy loads, ensuring cost savings while maintaining structural integrity. This choice saved money without compromising safety. Always verify that your steel resists corrosion and wear, especially in harsh environments.

Tip: Work with your supplier to identify cost-effective steel grades. Ask for samples or test reports to confirm quality before committing.

Streamline Construction for Efficiency

Efficient construction keeps your budget on track. Poor planning leads to delays, which drive up labor and equipment costs. Schedule tasks carefully and hire skilled crews who know steel structures.

Stadium 974's builders finished the project in under two years by optimizing workflows. They used prefabricated steel components and coordinated tasks tightly. This efficient way of working saves millions of dollars and significantly reduces labor costs. A streamlined process also reduces the risk of errors that require costly fixes.

Tip: Choose contractors with proven experience in steel structures. Review their past projects to ensure they deliver on time and within budget.

Stadium 974's efficient construction process cut costs and met tight deadlines.

Budget for Long-Term Maintenance

Steel structures may have relatively low maintenance costs, but they shouldn't be overlooked. If you don't have a long-term maintenance plan, maintenance expenses can quickly increase. Common maintenance methods, like

corrosion-resistant coating treatments, can effectively extend the life of steel structures and ensure cost savings.

For example, the steel structure of the Lusail Stadium put in place some pretty effective measures to prevent corrosion. The maintenance team came up with a solution that works well in Qatar's humid and high-salt environment, which helps prevent rust and make the structure stronger.

So, by doing regular inspections and maintenance, we can find out and fix potential problems quickly. This helps prevent internal structural deterioration and achieve cost savings. So, it's a good idea to plan for maintenance costs in the overall budget when the project is first being planned. That way, you can make sure it'll be cost-effective in the long run.

Tip: Allocate funds for maintenance in your budget. Ask your supplier about protective coatings and their long-term benefits.

Negotiate Smartly with Suppliers

Choosing the right steel supplier is a key strategy for keeping project costs in check. A lot of steel structure suppliers offer discounts for bulk purchases or flexible payment terms, which can help keep projects on budget. It's a good idea to compare quotes from different suppliers, thinking about price, quality, and service, to get the best deal.

For the Stadium 974 project, the negotiation team got some great deals on modular steel structure components. This not only had cost-saving benefits but also kept the structure strong. This case shows that working with reliable steel suppliers long-term can save money on current projects and get you better resources and supply guarantees for future ones.

Tip: Request detailed quotes from at least three suppliers. Discuss discounts, delivery timelines, and payment plans to maximize value.

Leverage Technology to Track Costs

Modern technology helps you stay on budget. Construction software like Building Information Modeling (BIM) tracks expenses and flags potential overruns.

Lusail Stadium's project team used BIM to monitor steel usage in real time. This ensured they stayed within budget despite the project's scale. Other tools, like cost-tracking apps, provide daily updates on spending. These insights let you adjust plans quickly and avoid financial surprises.

Tip: Invest in BIM or similar software. Train your team to use it for accurate cost management.

Draw Inspiration from Real-World Projects

Real-world projects show how smart budgeting pays off. Qatar's Lusail Stadium and Stadium 974 are prime examples. Lusail's team used high-strength steel and precise planning to build a world-class venue without breaking the bank.

The modular design of Stadium 974 proves that efficient design can deliver impressive results with cost savings. These projects highlight the power of clear scoping, modular designs, and strategic material choices. Apply these strategies to your steel structure project for similar success.

Lusail Stadium and Stadium 974 show how smart budgeting creates iconic steel structures.

Start Saving on Your Steel Structure Project

Are you planning a steel structure project and want to make the most of your budget? Smart planning and strategic decision-making can significantly cut costs without compromising on quality. At

XTD Steel Structure, we specialize in helping clients achieve their construction goals while staying within budget.

- Smart Budgeting Starts with Clear Planning

The first step to saving money on your project is defining the scope with clarity. Know what you need—and just as importantly, what you don't. A well-defined plan minimizes costly changes and delays later down the line.

- Modular Designs = Maximum Efficiency

Embrace modular and pre-engineered steel designs to streamline your construction process. These designs reduce labor, minimize material waste, and speed up completion time—all of which lead to major savings.

- Choose Cost-Effective Steel Without Compromising Quality

Not all steel is created equal. We help you select the right grade and type of steel that meets both your structural needs and your budget. Our extensive supplier network allows us to source high-quality materials at competitive prices.

- Streamline Construction with Professional Planning

Efficient construction means fewer delays and lower costs. We use advanced project management tools to optimize scheduling, coordinate teams, and manage every phase of your project from start to finish.

- Plan for Maintenance Early On

Maintenance is often overlooked in the early stages, but planning can save thousands in the long run. Our experts design structures with long-term durability and easy maintenance access in mind.

- Negotiate Smartly, Source Strategically

Working with XTD Steel means you'll benefit from our negotiation experience and supplier partnerships. We help you get the best deals, reduce waste, and avoid unexpected expenses.

- Use Technology to Track Every Dollar

From budgeting software to project tracking tools, we integrate technology that gives you real-time insights into your project's financial health. You'll always know where your money is going.

- Proven Strategies Backed by Iconic Projects

Projects like Lusail Stadium and Stadium 974 in Qatar are shining examples of how smart planning, modular systems, and budgeting technologies can result in world-class structures, completed efficiently and cost-effectively.