Space truss structure

Space truss structure development represents a paradigm change in structural engineering, where three-dimensional trusses efficiently transfer loads to several planes. This innovative technique of advanced truss building has enabled architects to conceptualize and realize ambitious projects that are beyond the reach of what is structurally feasible. From megairport terminals to Olympic stadiums, the systems illustrate the amazing abilities of contemporary engineering solutions.

Interesting Facts About Space Truss Structures

Space truss structures possess phenomenal characteristics that set them apart from conventional building systems. These are the facts that amaze a person to think about how advanced truss construction has become the first choice for the majority of mega-scale architectural designs.

Fascinating Facts About Space Truss Structures

There are some interesting facts about Space truss structures that you need to know. A few of the designs are not only aestetic, they're all about intelligent engineering, strength, and performance.

Fact 1: Able to span 100+ meters without supports

The most striking characteristic of modern truss construction is perhaps its ability to create huge column-free spaces. Space truss structures have the ability to freely span over 100 meters without support columns in between. This is because of their three-dimensional configurations, in which loads are resisted through a series of load paths simultaneously.

In modern truss construction

The record-breaking lengths of contemporary truss building have enabled the creation of enormous obstruction-free areas. The Guangzhou South Railway Station in China is a case in point, with more than 150-meter space trusses providing a cathedral-like interior to accommodate thousands of passengers in one go. This achievement shows how innovative truss engineering can transform utilitarian purposes into pieces of architectural poetry.

Fact 2: Often Used in Olympic Stadiums and Airports

Airports and Olympic stadiums are the epitome of modern truss use in buildings. They demand exceptional performance in span, beauty, and structural economy. The Beijing National Stadium, commonly known as the "Bird's Nest," is a demonstration of how space truss buildings can be used to deliver exceptional architectural forms while meeting exacting functional requirements.

Airport terminals particularly benefit from modern truss construction as they require huge open spaces for plane maintenance and passenger movement. The intricate spatial arrangement of space trusses allows one to create flowing, organic buildings that enhance the comfort of passengers while maintaining structural integrity. Terminal buildings like Dubai International Airport demonstrate how modern truss construction simplifies complex loading conditions while creating aesthetically pleasing spaces.

Fact 3: Weight-to-strength ratio beats many traditional systems

The efficiency of modern truss construction is evident when weight-to-strength ratios are compared to traditional structural systems. Space truss buildings usually have a 30-50% greater strength-to-weight ratio than traditional steel frame construction. That efficiency is due to the internal triangular shape of truss systems that forbids bending moments and relies almost solely on axial forces in structural members.

This improved performance characteristic of new truss construction translates into significant economic and environmental benefits. Reduced material usage means reduced construction cost, reduced transportation requirements, and reduced foundation systems. The reduced structural weight also allows more flexible architectural forms and reduces the overall environmental impact of construction activity.

Fact 4: Inspired by molecular structures and geometry

Geometric principles that control modern truss construction draw on nature in the guise of molecular patterns and mathematics. The tetrahedral and octahedral configuration commonly used in space trusses mimics efficient patterns of crystal lattices and molecular bonding. This biomimetic design process has yielded very efficient patterns of load distribution.

Buckminster Fuller's geodesic dome structures had a far-reaching influence on the development of space truss building techniques. His understanding of how geometric configurations could create maximum strength using minimum material set the stage for contemporary space truss design. Space trusses remain a research focus for engineers today, employing advanced computational methods to maximize truss structures to specified loading conditions and architectural requirements.

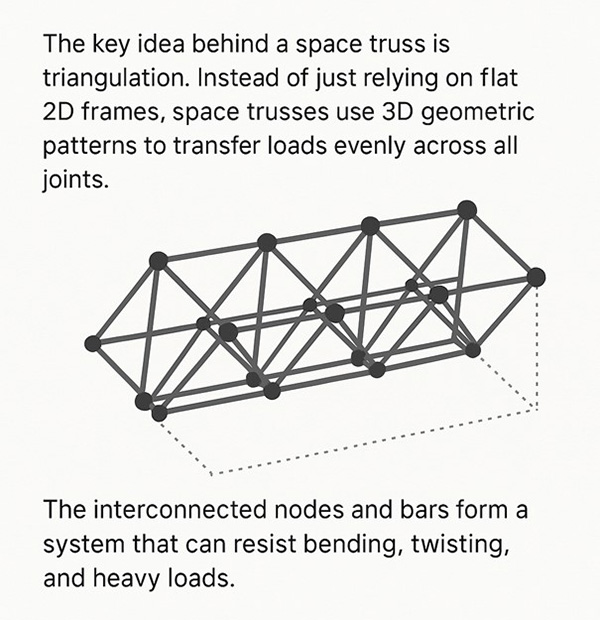

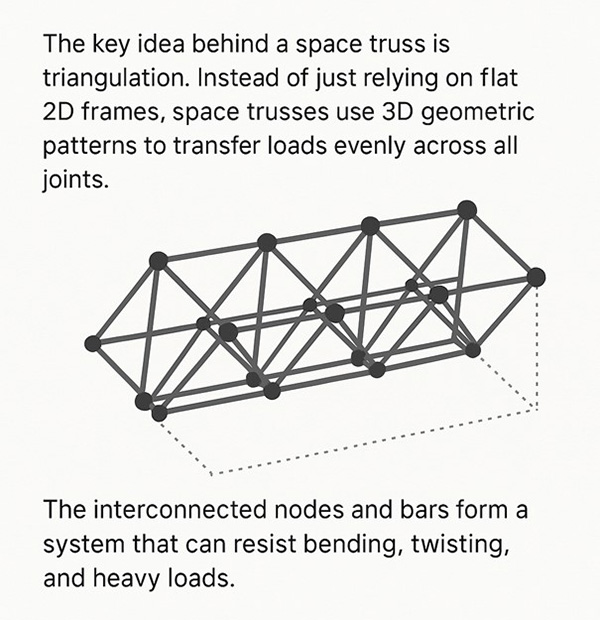

The Logic Behind Space Trusses

To better understand the engineering principles behind truss construction that ensure it remains so effective today, one should look at how forces pass through three-dimensional space trusses. Unlike traditional beam-and-column structures that rely on almost pure bending resistance, space trusses distribute loads in terms of axial forces along members.

The genius of modern truss design is the way it transforms complicated conditions of loading to simple tension and compression loads. When a space truss structure is loaded, three-dimensional geometry ensures that forces are distributed in many directions at once. This redundancy not only ensures structural safety but also allows for more efficient use of material.

Load distribution in modern truss buildings follows established principles of structural mechanics, but the three-dimensional nature of such systems provides special advantages. The nodes of the truss are where direct load transfer happens, with multiple members uniting to form rigid geometric assemblies. The members in triangular configurations within the truss system are unable to deform when carrying loads without failing members, thus stabilizing the system.

Mathematical treatment of space truss structures is a computationally challenging problem that includes sophisticated numerical methods for simulating the interaction between hundreds or thousands of discrete members. The most recent finite element analysis software can simulate such complex systems with unprecedented precision, allowing engineers to minimize member sizes and detail connection points for maximum efficiency. It was such computer-age processing of modern truss construction that enabled the achievement of more grandiose architectural visions.

Structural Redundancy and Safety Factors

New truss design encompasses several levels of structural redundancy that offer system safety overall. Whenever a member fails, the three-dimensional space truss geometry allows loads to be redistributed through other directions. The attribute, known as structural redundancy, provides an excellent safety advantage in comparison with statically determinate structures.

The current truss design approach is based on fail-safe behavior, with local failure never resulting in catastrophic structural collapse. This is achieved through careful attention to member connectivity, joint design, and load path continuity. Progressive collapse resistance is becoming an important consideration in recent truss design, particularly for high-profile public buildings.

One of the most critical aspects of modern truss work is connection design. Several members that meet at nodes have to be able to transfer forces without loss of geometric precision during construction. Welded and bolted assemblies each offer varying advantages depending on use and constraining construction factors.

Applications in High-Impact Architecture

Modern truss construction has enabled architects to create some of the boldest and dramatic buildings of the 21st century. Applications demonstrate how advanced structural engineering is able to further architectural intent as well as meet stringent functional requirements.

Stadium and Arena Construction

Sports stadiums are perhaps the most publicized manifestation of modern truss construction technology. The need for a huge, unobstructed viewing area makes beam-and-column construction outdated for all but a few stadium configurations. Space truss buildings make the spans desired and create the possibility for dramatic architectural design.

The London Olympic Stadium used new advanced truss construction methods to create an airy, demountable structure that would be reassembled after the games. This option confirmed that sustainable design trends could be merged with advanced structural engineering to create temporary but wonderful pieces of architecture.

Professional sports teams increasingly need facilities that provide excellent fan experiences while staying economically sustainable. Modern truss building enables architects to create distinctive roof shapes that optimize acoustics, provide weather protection, and accommodate complex mechanical systems. Retractable roof structures in the majority of modern stadiums rely largely on space truss concepts to supply the structural performance needed.

Airport Terminal Design

Terminal airports present unique challenges that make the most recent truss construction particularly attractive. The buildings must bear extreme spans, carry heavy roof loads, and provide flexible interior space to accommodate changing operating demands. The curving, organic lines popular in airport design coordinate beautifully with the geometric possibilities afforded by space truss systems.

Airports like Singapore Changi and Istanbul Airport illustrate the way modern truss construction can provide an outstanding architectural experience while meeting strict functional requirements. Column-free interior areas enabled by sophisticated truss systems enable one to enjoy smooth passenger movement while providing opportunities for natural lighting that enhances the travel experience.

Airport design security needs have also identified the importance of modern truss building. The adaptability of achieving vast open areas with minimal quantities of supporting structure increases visibility for security officials and reduces the number of hiding places for people in terminal structures.

Exhibition and Convention Centers

Convention centers and exhibition halls constitute another significant area of application for modern truss construction. These buildings call for maximum versatility for temporary installations and must be able to accommodate radically different loads depending on the events to be supported. Space truss buildings provide the open spans necessary for large exhibitions as well as the structural capacity to support heavy suspended loads.

The prefabricated nature of most space truss systems is in harmony with the expansion needs typical of convention facilities. Phased construction utilizing modern truss construction techniques allows for the addition of extra bays without disrupting in-progress operations. Such flexibility has established space trusses as the structural system of preference for the majority of convention center projects worldwide.

Design Software and Computational Tools

| Software Tool |

Main Function |

Strengths in Space Truss Design |

Best Used By |

| SAP2000 |

Structural analysis and design |

Excellent at analyzing load paths, forces, deflections, and structural behavior |

Structural engineers |

| ETABS |

Building system modeling and structural analysis |

Good for integrating space trusses with vertical structures (e.g., buildings, columns) |

Structural and civil engineers |

| Rhino + Grasshopper |

3D modeling and parametric design |

Ideal for creating complex geometries and optimizing truss layouts in real time |

Architects, designers, computational modelers |

The complexity of modern truss construction requires sophisticated software tools that can accurately simulate three-dimensional structural behavior. Present-day practice relies heavily on specialized programs that can optimize member dimensions, compute connection forces, and cope with intricate geometric relationships

SAP2000

SAP2000 is the standard industry tool for the analysis of complex space truss structures in modern truss construction projects. The high-performance finite element analysis program can simulate the nonlinear responses of truss systems under any kind of loads, including stability and dynamic effects.

The ability to handle large models with thousands of entities makes the program particularly attractive for application to modern truss construction. Engineers can investigate load redistribution patterns, optimize member sizes to be as small as possible while being as efficient as possible, and verify connection capacities in the structure. Integration into building information modeling (BIM) workflows has also widened the application of SAP2000 in recent practice.

SAP2000's sophisticated functionality supports the specialized requirements of modern truss building schemes. Parametric modeling functionality allows engineers to rapidly examine various solutions at the design stage, and automated optimization routines can ascertain the most economical member sizes to achieve specified performance goals. Such computational techniques have facilitated a level playing field for high-end structural analysis access, whereby smaller engineering practices can now carry out intricate space truss tasks.

ETABS

ETABS possesses specific functionality to combine space truss structures with building systems in modern truss construction works. The software can strongly model the interaction of structural trusses with other elements of a building, including floor systems, lateral force-resisting elements, and foundation systems.

Building-specific elements of ETABS make the design process easier for modern truss construction projects for mixed-use complexes. Engineers can model complete building systems wherein space trusses fulfill the role of long-span capacities for specific areas while conventional framing systems function for standard office or residential spaces. This complementary approach ensures integration among several structural systems for a single project.

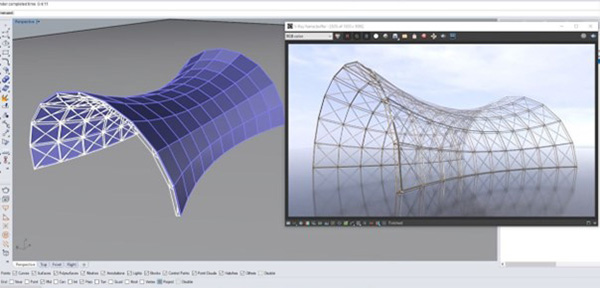

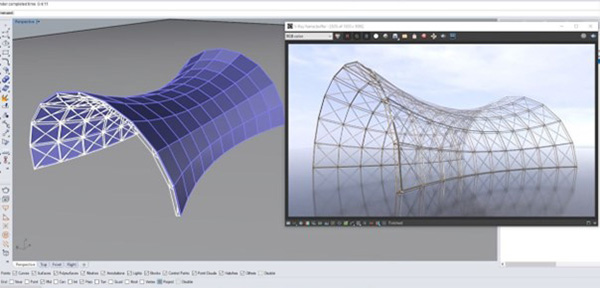

Rhino + Grasshopper

The combination of Rhino 3D modeling software and the Grasshopper parametric design plugin has revolutionized the early design phases of modern truss construction projects. The software and plugin enable designers and engineers to explore complex spatial relationships and systematically optimize truss geometries with respect to a multiplicity of performance goals simultaneously.

Grasshopper's graphical user interface allows design teams to create parametric models where geometrical changes propagate automatically throughout the entire truss system. Such a capability is particularly handy in today's truss construction because slight changes in node positions or member orientations can significantly impact structural performance as well as constructability.

The integration of conceptual design and structural analysis software has made the development process more efficient for today's truss construction projects. The design teams can easily transition between multiple alternatives, evaluating architectural and engineering performance criteria before completing detailed development. This integrated process is one factor that has contributed to the increased complexity and productivity of today's space truss structures.

Material Innovations in Modern Truss Construction

Contemporary space truss structures also benefit from significant advancements in materials technology that support the use of contemporary truss building. High-strength steel, high-tech aluminum alloys, and composites all have unique strengths as materials for specific project requirements.

High-Strength Steel Uses

Modern high-strength steels provide superior performance characteristics for space truss construction with yield strengths significantly higher than those of conventional structural grades. Space truss construction can be achieved more lighter and more efficiently and can span longer with smaller members.

Weathering steels have been found to have particular application in exposed space truss members where maintenance access is limited. Weathering steel surfaces' protective oxide layer eliminates the need for constant painting maintenance while providing adequate corrosion protection in most environments. This property makes weathering steel particularly attractive for extended service life in modern truss building construction works.

The development of ultra-high-strength steels with yield points over 700 MPa has opened new possibilities for very efficient space truss systems. These materials, however, require attention to connection design and fabrication techniques in order to utilize them fully in modern truss application.

Aluminum Alloy Systems

Aluminum space truss structures offer a number of advantages to modern truss construction schemes where weight saving is of the highest priority. Due to the high strength-to-weight ratio of aluminum alloys, combined with inherent resistance to corrosion, such materials are best suited for long-span roof framing and temporary fixing.

The modular connection systems conventionally used with aluminum space trusses enable quick construction and potential reuse of the structural members. This aspect is in concordance with sustainability objectives and has made aluminum systems extremely popular among exhibition buildings and temporary facilities where progressive truss construction techniques ought to be capable of responding to changing functional requirements.

Composite Material Integration

Very advanced composite materials are beginning to find applications in advanced modern truss structures where their unique attributes are justifiable in extra material expense. Carbon fiber reinforced polymers offer outstanding strength-to-weight values and are also designed to be made responsive to unique loading conditions through control of the orientation of fibers.

The non-corrosive nature of composite materials renders them extremely attractive for modern truss construction in harsh conditions in which steel structures would require a lot of maintenance. However, connection design and fire protection concerns currently inhibit application extension into specialized projects in which advantages far outweigh additional cost and complexity.

Construction Methodologies and Assembly Techniques

Effective implementation of modern truss construction projects requires painstaking planning of methods for assembly and sequences for construction. Space truss structures with their three-dimensional complexities present unique challenges that must be addressed by using specialized methods for construction.

Prefabrication and Modular

Prefabrication is a key part of modern truss construction, enabling quality control and productivity of construction at or near the boundaries of field assembly of separate pieces. Modular systems enable entire sections of trusses to be made in controlled shop environments before being shipped to the construction site.

The modularity of modular space truss systems reduces fabrication cost and simplifies construction planning. Repetitive connection details and member dimensions enhance more effective manufacture with less opportunity for construction mistakes. This approach to modern truss construction has proved most useful for large projects where construction schedule constraints are an issue.

Temporary bracing systems must be carefully designed in modern truss construction projects because three-dimensional stability in space trusses is dependent on complete geometric configurations. Incomplete assembly may not be enough to provide stability, and temporary bracing systems must be removed with the progress of construction. This sequence complexity demands precise planning and construction crews that have expertise.

Installation of massive space truss assemblies poses a significant challenge that necessitates specialized lifting equipment and carefully planned construction sequences. Modern truss building construction projects often include the final placement of complete roof sections of hundreds of tons using coordinated crane lifts.

Ground assembly techniques allow optimum use of prefabricated components with minimum amount of high-altitude work on site. Complete space truss sections can be constructed at ground level before being hoisted into position, allowing for reduced construction time and worker safety. This method does require adequate laydown space and adequate crane capacity to execute the lifts.

Strand jacking systems provide an alternative lifting method for modern truss construction projects where conventional crane access is limited. Strand jacking systems are able to lift very heavy loads by synchronized hydraulic jacks mounted on high-strength cables to allow space truss structure installation in densely populated urban areas or over structures.

The Future of Space Truss Structures

Emerging technologies and shifting design philosophies are shaping the future of modern truss construction. Artificial intelligence, innovative materials, and sustainable design philosophies are converging to create novel opportunities for space truss applications.

Digital Design Integration

Building Information Modeling (BIM) technologies transform the design, coordination, and construction of today's truss building projects. Computer workflows embedded in an integrated manner enable coordination between architectural design, structural analysis, and fabrication operations, reducing errors and increasing construction efficiency.

Generative design allows software to begin to spearhead space truss optimization, automatically browsing hundreds of designs to arrive at optimal solutions for specific performance criteria. The computer-based solutions to modern truss construction can address more than one objective simultaneously, including structural performance, cost of materials, building complexity, and aesthetics.

Virtual and augmented reality software are enhancing the design review process for new truss building projects. Designers are able to experience full-size space truss structures during the design phase, identifying any issues and optimizing user experiences before construction. The immersive tech is most applicable for complex public buildings where stakeholder involvement is important to the success of a project.

Adaptive and Smart Structures

The integration of sensors and control systems in space truss structures is making adaptive buildings that respond to dynamic environmental conditions possible. Smart modern truss building incorporates structural health monitoring systems that can detect damage, track performance, and optimize building activities in real time.

Self-forming space truss structures are a new frontier for modern technology in truss construction. Space truss structures that rely on this technology can be altered in their geometry in accordance with loading conditions, environment, or functional requirements and become active responding buildings.

While employed currently only for research, the technology can profoundly alter how one thinks of static architectural building structure.

Sustainability and Life Cycle Considerations

Sustainability concerns are increasingly important in

modern truss construction methods, with an emphasis on material efficiency, minimizing waste in the course of construction, and recyclability at the point of disposal. The intrinsic efficiency of space truss architecture is particularly amenable to sustainable design, but emerging practice is extending this.

Circular economy principles are being applied to modern truss construction by the development of demountable connection systems, which enable the reuse of the entire structure. These practices consider that uses of a building may change over time and design buildings for ease of disassembly and reformatting to new purposes.

Carbon footprint reduction is going mainstream to consider in modern truss building designs, with life cycle studies guiding material selection and structural design. Advanced optimization software can now consider embodied carbon alongside traditional performance drivers, towards more environmentally friendly structural designs.

Why Engineers Must Adopt the Truss Revolution

The considerable advantages of modern truss construction go much further than simple structural efficiency. Design principles of space trusses learned by engineers position them at the cutting edge of architecture while contributing to more sustainable and efficient building practices.

Professional education in modern truss construction requires knowledge of elementary structural principles as well as cutting-edge computational technology. The complexity of three-dimensional systems of structures necessitates mathematical sophistication, but the payoff is accomplishment of architectural fantasy that is not possible with conventional systems of structures.

Greater demand for column-free, long-span spaces in contemporary architecture ensures constant demand for the services of contemporary truss construction. Throughout commercial building and arena sports applications, architects are increasingly turning to space truss solutions to aid their design aspirations. Highly-skilled engineers within this discipline are in high demand throughout numerous market sectors.

Innovative opportunities in modern truss design continually expand with emerging materials, construction methods, and design software on the horizon. Designers embracing these emerging technologies can propel the state of practice ahead while gaining specialized professional expertise that sets them apart in an open marketplace.

The integration of sustainability principles and structural optimization presents challenges and opportunities for modern truss construction practitioners. Engineers who can balance performance, economy, and environmental sustainability will be well placed to lead the profession as sustainability assumes increasing prominence in construction practice.

Final Thought

Space truss construction is one of the major developments in structural design allowing architects and engineers to design buildings which were previously unrealizable or far too costly. Geometric, structural, and architectural efficiency with flexibility provided by space truss structures has made them an indispensable tool in current building practice.

The prospects for contemporary truss construction are bright, with impending technologies promising even greater capacity and effectiveness. Computer-aided design software, emerging materials, and sustainable building practices are converging to enable new applications for space trusses. Designers who specialize in this rapidly evolving field will be at the forefront of architectural design.

Understanding of space truss building principles has become imperative for the engineers who work on large-scale architecture projects. Structural economy and mathematics of space truss systems are the keys to some of the most challenging issues facing contemporary construction. As buildings become more advanced and performance standards more demanding, application of new structural systems like space trusses will continue to gain in importance.

New truss construction revolution isn't just about structural efficiency—it's about making architecture dreams possible that inspire and serve human needs more effectively. Through embracing such sophisticated structural systems, engineers assist in creating built environments that are more efficient, more sustainable, and better aligned to the diverse demands of contemporary society.