For

prefabricated buildings, the design of the floor is extremely important, as it will affect the safety and economic impact of the structure. Therefore, this article will systematically introduce the regular maintenance of steel structure engineering, the advantages and disadvantages of the steel structure engineering system, and the importance of enclosure material selection.

1. Maintenance requirements for steel structure buildings

As we all know, the "Bird's Nest" built for the 2008 Summer Olympics in Beijing was built with steel structure. At the same time, steel structure has an obvious disadvantage that it is easy to corrode. According to incomplete statistics, the economic cost of material corrosion in the world accounts for about 3-5% of the gross national product every year, and the cost of corrosion in China is equivalent to 3.4-5% of the national GDP every year. The reference value of the relatively economical and durable years of regularly maintained steel structure houses is generally: 70 years, while the average of reinforced concrete structures (including frame structures, shear wall structures, cylinder structures, frame-shear wall structures, etc.) is 50 years. It can be seen that regular maintenance and maintenance of steel structures after construction is completed is particularly important.

However, in the investigation process in recent years, it was found that some users of steel structures did not know that steel structures needed to be regularly maintained and maintained, resulting in serious corrosion conditions, and in places where users often could not find them, this caused many unsafe hidden dangers in the already seriously corroded steel structure products, thereby reducing the safety and normal functional use of steel structures in use and function. Below I will correctly explain the requirements and use of steel structures in maintenance and maintenance.

1. Maintenance and care:

If the steel structure is exposed to the air for a long time or in an environment with low humidity, and there is no anti-corrosion material protection on the surface, the steel structure will be corroded, deformed, and stress-failed, causing the steel structure to break prematurely. Here, if the steel structure is to work normally and have the expected service life, regular inspection, maintenance and care of the steel structure are very important. The maintenance and care of the steel structure mainly involves regular anti-corrosion, anti-rust, and fire prevention treatment and protection, and checking whether it is deformed (such as: vertical structure, plane bending, and bending and span change of main components during use)

2. Regular anti-corrosion treatment:

Generally, the service life of the steel structure is fixed at about 50 years when it is designed. During use, the possibility of the steel structure being damaged due to overload is very small. Most of the damage to steel structures is basically caused by corrosion. Under normal circumstances, steel structures need to be maintained once every 3 years. At the same time, when dealing with anti-corrosion, the type and specification of the paint must be the same as the original paint coating. If the two paints are different, the coating will not meet the anti-corrosion requirements, causing greater harm.

2. How to choose the material of the enclosure system and its importance

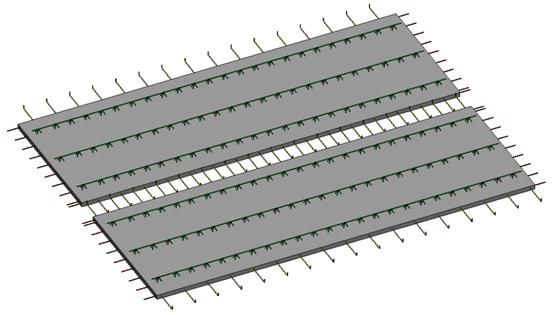

At present, steel structure projects are widely used in various construction fields. At the same time, corrugated steel plates are also used in the maintenance system of steel structure workshops. The various types of corrugated steel plates can meet the structural functions in architectural performance, but their economic efficiency must be considered. Therefore, when choosing what kind of plate type building materials, the following factors need to be considered comprehensively.

https://www.xtdsteel.com/products/single-board-maintenance--floor-board-series-/

1. The enclosure system is very important in terms of material selection. In terms of material durability, the material's anti-aging, anti-weathering and anti-deformation capabilities have already determined the service life of the enclosure system and the solidity of the building structure. From an aesthetic point of view, the architectural style highlights the color and texture, creating a unique architectural image. From an aesthetic point of view, at the beginning of the design of the architectural style, it has been clearly expressed that the color and texture requirements of the materials are required to build an ideal architectural image. From an economic point of view, they include the initial investment cost and the subsequent maintenance and replacement costs, which have a significant impact on the overall budget and long-term benefits of the construction project.

2. Strength: It has to bear external loads such as wind, thunder, and rain, which is the primary consideration for selecting the plate type. Generally speaking, the higher the wave crest, the greater its cross-sectional inertia: the denser the wave crest and the thicker the base plate, the higher its strength, but at the same time the amount of steel used will also increase, and the spacing of the purlins needs to be considered. The larger the spacing, the greater the strength requirements of the steel plate.

3. Plate-type building materials have extremely strict requirements on other aspects of the structure, such as fire protection and thermal insulation.

https://www.xtdsteel.com/products/single-board-maintenance--wall-sandwich-panel-series-/

4.

Different buildings have different requirements for insulation and fire protection. The specific requirements are as follows:

- Pressure steel plate: non-combustible, fire resistance limit 15 minutes.

- Polystyrene sandwich panels: oxygen index ≥ 30%, foam volume density ≥ 15 kg/m3, thermal conductivity ≤ 0.041 W/mk; due to the low fire resistance level, it is rarely used in formal projects. (Data available)

- Rock wool sandwich panel or glass wool panel: inorganic material, non-combustible, thickness ≥ 80 mm, fire resistance ≥ 60 min, thickness < 80 mm, fire resistance ≥ 30 min, bulk density ≥ 100 kg/m3, thermal conductivity ≤ 0.044 W/mk. The dead weight is large, and the installation site of glass wool panel is more complicated and cumbersome. (Data available)

- Rigid polyurethane sandwich panel: B1 grade building material, foam volume density ≥ 30 kg/m3, thermal conductivity ≤ 0.027 W/mk, high strength, good appearance, but high cost. Rigid polyurethane foam is currently a better building insulation material, with low thermal conductivity, good bearing capacity, high bending strength, good water absorption, no decay, anti-insect and anti-rat bite, relatively good flame retardant performance, and a wide range of applicable temperature. (Data available)

- Usually, aluminum-zinc-plated colored steel plates or aluminum-plated steel plates are used. When choosing the base plate, the thickness and manufacturer should be selected according to the actual use requirements and functional requirements. The thickness of the corrugated steel plate should not be too thin, and the thickness is preferably 0.4~0.8mm. If the color plate of the roof outer plate is too thin, after a period of use, it will cause the outer plate to corrode, deform due to temperature, and the pressure of snow on the plate, causing the gap between the plates to increase.

Advantages and disadvantages of the steel structure engineering system of the enclosure system

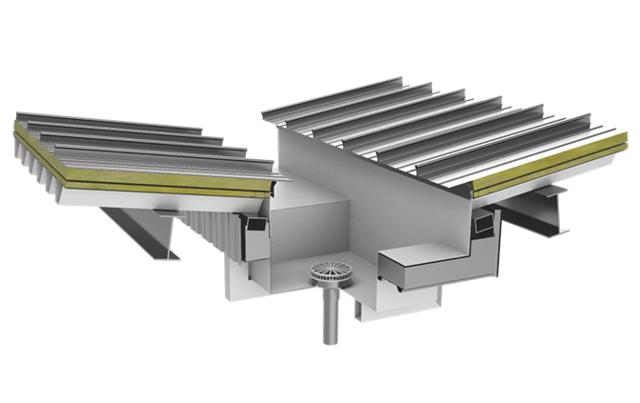

1. The enclosure system is made of finished products and can be used repeatedly. Its construction method is also relatively convenient. However, after repeated use, there may be leakage, so more attention should be paid to strengthening waterproof measures during installation.

2. The steel structure of the enclosure system is noisy during construction. Cranes are generally not used for large-span roof installation during construction. Since the rigidity of the enclosure system is small, the color plate will be deformed when installed with a crane, so most of them use semi-inclined lifting.

3. The edging and flashing of the enclosure system can not only perfectly outline the lines of the building, but also bring visual design to the beauty of the building, and connect the building into a whole in the structure, which can achieve better wind and rain protection, making the building stronger and more durable.

Summarize

The steel structure engineering system of the enclosure system uses less steel, has a shorter installation and design time, and is widely used in industrial production of steel structures. It is currently widely used in scenes such as factories and small exhibition halls. At the same time, the enclosure system used to use color steel plates. When constructing the external building-type layer panels, it is necessary to give priority to the use of concealed color steel plates, which can effectively avoid thermal expansion and contraction, which may cause the self-tapping screws to be cut off, and can also avoid aging of rubber pads in rainy areas or typhoon areas, causing rust and leakage of the panels.

In areas with less rain in the north, it is recommended to use free-falling eaves. It is more economical and has better waterproof performance. It is widely used when the project does not require high eaves.

https://www.xtdsteel.com/products/engineering-supporting-products--c-type-z-type-angle-steel-channel-steel-square-tube-etc-/