Are you thinking of building with modular steel structures? Well, you have a lot of choices to make and considerations to take into account. These versatile, cost-effective solutions offer numerous benefits over traditional construction methods. However, selecting the right modular system requires careful analysis. Prefabricated steel structures and modular steel frames should also be checked regarding building codes, site conditions, problems with customization, and extensive long-term development prospects. This article focuses on important considerations to help you choose a modular steel structure that meets the requirements of the project and the set budget.

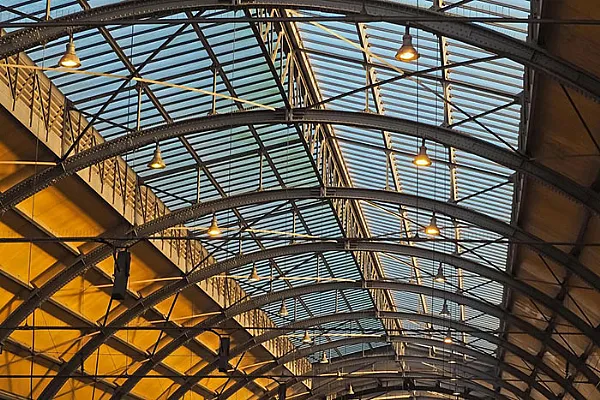

The Benefits of Modular Steel Structures

Cost-Effective Construction

A modular steel structure has a cost advantage over conventional construction methods. Much of the work is usually done off-site, minimizing the work done at the site and, thus, construction expenses. Moreover, the reduced time to erect the building cuts the cost of financing and organizing its use.

Rapid Assembly and Flexibility

Modular steel buildings can be assembled in the shortest possible time, much shorter than that needed for traditional construction. This makes them suitable for time-bound projects. The modular concept is also quite friendly in that it accommodates expansion or reconfiguration in the future as requirements change.

Durability and Sustainability

The modular nature of steel structures provides a unique balance of strength, resilience, and adaptability, making them a preferred choice for modern construction projects. Unlike conventional building materials that may degrade over time, steel maintains its structural integrity for decades, ensuring that buildings remain safe and dependable long after completion. The inherent toughness of steel allows these structures to withstand the pressures of heavy loads, intensive use, and even expansion or modification when future needs arise.

One of the most significant advantages lies in their ability to resist natural forces. Modular steel structures are designed to endure extreme climatic conditions, from high winds and heavy snow loads to seismic activity. Their flexibility and engineered connections reduce the risk of structural failure during strong storms or earthquakes, providing an additional layer of safety and confidence for occupants. This resilience is particularly valuable in regions prone to harsh weather, where traditional building methods may struggle to deliver the same level of protection.

From an environmental perspective, modular steel construction offers sustainability benefits that align with global green building initiatives. Steel is one of the most recyclable materials on the planet, allowing structures to be dismantled, repurposed, or melted down for reuse without losing quality. This circular approach to construction minimizes waste and ensures that valuable resources are conserved. Additionally, modular fabrication processes are highly precise, which drastically reduces on-site waste compared to conventional building methods.

Energy efficiency is another key factor. By leveraging advanced manufacturing technologies, modular steel structures can be produced with less energy consumption and greater precision. This results in not only lower operational costs during construction but also long-term efficiency in the building’s performance. Many designs incorporate insulation, energy-saving features, and eco-friendly finishes that further reduce the carbon footprint.

In essence, durability and sustainability go hand in hand with modular steel structures. They not only offer unmatched robustness and resilience but also contribute to environmentally responsible construction practices. This combination makes them an ideal solution for businesses, communities, and governments seeking to create infrastructure that is strong, future-proof, and respectful of the planet’s resources.

Types of Modular Steel Structures: Pre-Engineered vs. Custom

The modular steel structure types available to you are pre-engineered and custom buildings. Each gives certain benefits and addresses certain needs.

Prefabricated Modular Steel Systems

Buildings constructed using pre-assembled steel structures are referred to as pre-engineered. These structures tend to have the following advantages:

- Affordable: The mass production of products reduces the general costs incurred.

- Quick turnaround: There are shorter periods for assembling.

- Reliability: Production standardization leads to quality uniformity.

- Flexible: Further additions to the structure can easily be made to the existing one.

On the contrary, pre-engineered steel buildings are deficient in architectural detailing.

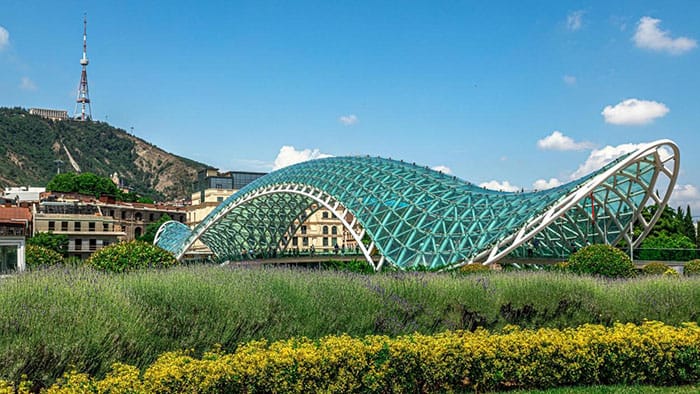

Custom-Designed Modular Steel Structures

Custom-designed steel buildings provide greater flexibility and are tailored to specific requirements:

- Unique designs: Architects can create distinctive aesthetics.

- Specialized functionality: Structures can be optimized for specific uses.

- Site-specific adaptations: Designs account for local conditions and regulations.

- Integration of special features: Accommodate non-standard equipment or processes.

While custom designs offer more possibilities, they typically involve higher costs and longer production times.

Choosing between pre-engineered and custom-designed modular steel structures depends on factors like budget, timeline, and aesthetic preferences. Carefully weigh these options to select the type that best aligns with your project goals and constraints.

Key Factors to Consider When Choosing Modular Steel Structures

Several crucial factors come into play when selecting modular steel structures. Understanding these elements will help you choose a solution that suits your needs and finances.

Purpose and Design

Consider the intended use of your modular steel building type. Will it serve as a warehouse, office space, or manufacturing facility? This, in turn, will inform the design requirements, such as layout, insulation, and the kind of interior finishes. The manufacturer should be able to make your desired structure as per your requirements.

Size and Scalability

Identify the current and projected space needs. One advantage of modular steel buildings is that they are scalable. Select a design amenable to future expansion or alteration as the need arises. This flexibility can be very beneficial and thus cheap in the long term.

Building Codes and Regulations

Research the local building codes, zoning regulations, and other requirements to obtain a permit in your area. There are structural requirements that modular steel structures have to satisfy, but these requirements are not always the same for every jurisdiction. You should select a manufacturer with experience with these requirements to facilitate the approval process.

Cost and Budget Considerations

Modular steel buildings are indeed relatively cheaper than conventional construction techniques. However, cost comparisons are very relative, and therefore, one has to take them with caution. Consider not only the purchase price but also all future costs. This includes maintenance, energy savings, and extending the structure’s life cycle. Always ask for similar quotes from several manufacturers to arrive at very good options regarding the value for money.

Estimating the Cost of Modular Steel Buildings

Having decided to incorporate modular steel into your project, there are several cost factors you’ll have to consider. Although their price is lower than normal construction of such structures, several factors can change that.

Base Pricing and Customization

Typically, the base cost of a modular steel building includes the primary frame, roof, and walls. Nonetheless, add-ons such as internal fittings, insulation, etc., increase costs. The cost factor should be in tandem with the client’s specific requirements.

Size and Complexity Considerations

Larger structures generally cost more. Therefore, larger buildings invariably have higher costs, though, to some degree, the cost per square foot becomes cheaper. Constructing a simple rectangular building may not be very costly. However, purchasing to construct more intricate architectural construction designs would be more costly.

Site Preparation and Foundation

Additional costs must always be accounted for on the site. The expenses involved in land clearing, grading, and foundation work are location—and soil-condition-specific. Such factors should be considered early in the planning phase when budgets are drawn.

Delivery and Installation

The manufacturing facility may be far from the site, so you must be prepared for transportation costs. Furthermore, installation costs may differ depending on the steel structure design and the local labor cost. Certain material providers will do the construction, while others will ask you to source construction work from other contractors.

Frequently Asked Questions About Modular Steel Frames

Which modular steel frames have some important positive aspects?

Such concrete structures as those constructed with modular steel frames have some great attributes, including speed of erection and lower costs. These types of construction can be put together on-site quicker as there is less labor and time on the project schedule. Due to the off-site nature of construction, quality control is very efficient, and less raw material is wasted. Also, because they are modular steel structure frames, there is always room for even more construction in the future.

How long do modular steel structures last?

Indeed, modular steel structures are very strong and can withstand difficult weather circumstances. They are designed to endure considerable temperature and weather changes, strong winds, and earthquakes. Each steel part is coated to protect from rust, making them better than most building materials. Maintenance done appropriately can see such structures last for many decades.

Is it possible to use these modular steel frame systems in any building?

Yes, modular steel frames are not limited to one purpose and can be used for many purposes. This product’s usage characteristics are acceptable for residential, commercial, and industrial construction. Modular steel structures are one-stop solutions for all kinds of architectural requirements, whether warehouses, office buildings, schools, or health facilities. Their properties make them ideal for both temporary and permanent buildings.

Final Thoughts

When selecting modular steel structures for your project, it is essential to approach the decision with a clear understanding of your priorities and objectives. Beyond the technical aspects, you should also align your choices with long-term project goals, operational efficiency, and future scalability.

Start by evaluating your personal preferences, project requirements, and the market opportunities available to you. A well-thought-out budget plays a vital role, ensuring that your investment delivers the highest value while minimizing unnecessary prefabrication costs. At the same time, compliance with local building codes, safety regulations, and environmental standards must remain at the core of your planning process to guarantee both legality and sustainability.

Additionally, consider the range of features that modular steel structures offer, from energy efficiency and durability to design flexibility and customization. Researching and comparing reliable suppliers will give you the confidence to select a partner who not only delivers quality products but also offers support throughout construction and beyond. By balancing cost, quality, and service, you set your project on a strong foundation.

Ultimately, choosing a modular steel structure means investing in a solution that is durable, flexible, and prepared to meet future demands. With the right planning and supplier partnership, you can rest assured that your modular steel frame will stand strong for years to come, delivering functionality, resilience, and long-lasting value.