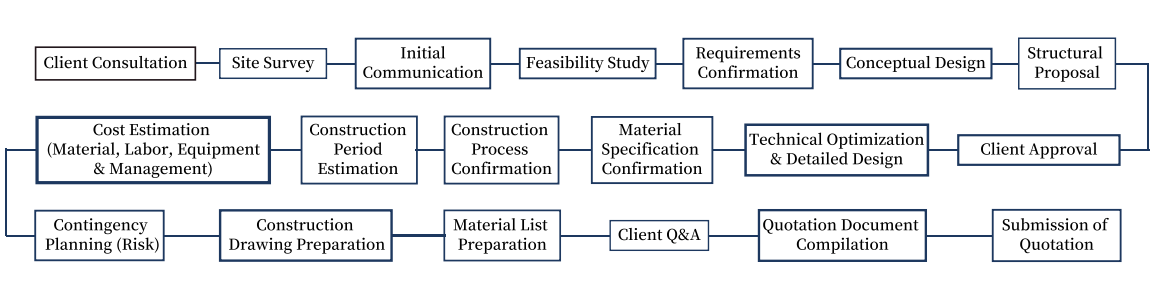

The solution consultation process is an important preparatory phase prior to project commencement. The design team will propose preliminary ideas for steel structure materials, technical choices, and design schemes based on the building's intended use, site conditions, and budget. Scheme consultation not only involves overall layout and functional analysis but also considers various issues that may arise during on-site construction, helping clients understand the project's feasibility from multiple perspectives. Scientific scheme design can reduce risks, ensure smooth construction, and guarantee the long-term safety of the steel structure.

Client Consultation

This step involves multiple rounds of in-depth communication with the client to fully understand the project objectives, aesthetic preferences, and specific functional requirements. Technical personnel will provide detailed explanations of the characteristics of different steel structure systems to assist clients in comparing and selecting the most suitable solution. Clear alignment of requirements not only ensures that the design better meets actual usage needs but also addresses potential conflicts in advance, ensuring that the overall construction schedule aligns with client requirements. This is a critical step in ensuring the smooth execution of the design.

Site Survey

This step is conducted to obtain accurate information on terrain, geology, and surrounding environmental conditions, and to propose scientifically sound foundation and structural layout recommendations based on site characteristics. Engineering personnel will focus on factors such as foundation bearing capacity, site drainage, surrounding obstacles, and transportation access routes, providing reliable data support for subsequent design development. A comprehensive site survey effectively mitigates safety risks caused by geological conditions, reduces uncertainties during the construction phase, and ensures engineering quality and overall project progress.

Initial Communication

This step is an important process for refining and confirming the design. The design team will engage in repeated discussions with the client regarding structural forms, architectural styles, node details, and material usage. Through thorough communication, technical feasibility and construction convenience are clarified, reducing the risk of subsequent design modifications. A well-structured communication process ensures that client preferences are accurately reflected while providing a solid foundation for construction drawing development and budget preparation, thereby enhancing overall project efficiency.

Feasibility Confirmation

This step involves a comprehensive technical and economic analysis of the project to assess its feasibility. The study covers various aspects, including structural safety, construction feasibility, material supply, post-construction maintenance, and environmental requirements. Through comprehensive comparisons, optimized solutions and risk control measures are proposed to assist clients in making informed decisions. A well-structured feasibility study not only improves overall efficiency but also reduces investment risks, serving as a crucial safeguard for the smooth progression of the project.

Requirements Confirmation

This step formally documents and confirms the client's functional requirements, aesthetic preferences, spatial layout, and performance metrics, establishing a critical foundation for subsequent design and construction. Through detailed communication and written confirmation, all requirements are ensured to be incorporated into drawings and proposals, avoiding cost increases and schedule delays caused by frequent changes later on. A clear requirement confirmation document is a prerequisite for efficient project implementation and a key foundation for ensuring the project outcomes align with expectations.

Conceptual Design

This step involves preliminary conceptualization and overall design presentation of the building's exterior, structural system, and spatial layout based on the confirmed requirements. Designers will combine aesthetics, mechanics, and construction techniques to propose visual solutions and generate schematic diagrams, facilitating client understanding of the overall effect and technical approach. A comprehensive conceptual design not only establishes the direction for detailed construction drawings but also provides reference criteria for budgeting, material procurement, and construction scheduling, enhancing efficiency in subsequent phases.

Structural Proposal

This step involves further developing detailed structural layouts, beam and column cross-sections, node connections, and construction details based on the conceptual design outcomes. Engineers provide professional recommendations by combining load analysis and construction feasibility, ensuring a balance of overall safety, stability, and cost-effectiveness. A well-developed structural recommendation helps reduce design modifications and construction challenges in later stages, improving overall construction efficiency and product quality, and is a crucial guarantee for achieving high-quality engineering.

Client Approval

This step is a critical process where the client provides final confirmation of the conceptual design and structural recommendations. Through comprehensive review and detailed discussion, both parties reach a consensus and formalize a confirmation document, which serves as the foundational basis for construction drawings and procurement contracts. Accurate client confirmation effectively avoids subsequent design changes and contractual disputes, ensuring smooth construction progress and aligning the final building outcomes with client expectations, thereby setting the stage for all subsequent work.

Technical Optimization & Detailed Design

This step involves technically refining the final design outcomes and providing detailed explanations of design key points to the construction team. Content includes node construction methods, connection details, construction sequence, and process standards to ensure that design concepts and details are accurately translated into practical operations. A comprehensive technical briefing reduces misunderstandings, lowers construction risks, enhances on-site execution efficiency, and improves engineering quality, serving as a critical link for seamless integration between design and construction.

Material Specification Confirmation

This step involves confirming the type, performance, and treatment methods of the steel, bolts, welding materials, and coating materials to be used based on design requirements. Engineers will propose the optimal material selection scheme by considering the usage environment, corrosion and fire resistance performance, and maintenance requirements. A standardized material specification confirmation helps control engineering quality and costs, prevents safety hazards and rework issues caused by non-compliant materials, and is an important step in ensuring the overall structural safety and reliability.

Construction Process Confirmation

This step involves the comprehensive planning and confirmation of the construction processes for component manufacturing, transportation, on-site assembly, and overall installation. By clearly defining the operational key points and quality requirements for each phase, it ensures smooth coordination between construction stages. A well-defined construction process confirmation reduces on-site issues, enhances construction safety and efficiency, ensures stable engineering quality, and achieves the intended design objectives, serving as a critical guarantee for the successful completion of the project.

Construction Period Estimation

This step involves a scientific analysis and reasonable estimation of the overall construction timeline based on the design plan, material delivery schedules, site conditions, and work sequence arrangements. A reasonable schedule helps coordinate construction resources, minimize waiting times and conflicts, and ensure timely delivery. Accurate construction schedule estimation not only improves on-site construction efficiency but also enhances client confidence, serving as a critical basis for ensuring the orderly execution of the project plan.

Cost Estimation (Material, Labor, Equipment & Management)

This step involves a comprehensive analysis and estimation of costs related to material procurement, construction personnel, machinery and equipment, and overall management. Through detailed cost breakdowns, clients can gain a comprehensive understanding of investment composition and optimize budget arrangements. Scientific and reasonable cost estimation reduces the risk of overspending, improves project fund utilization efficiency, and provides a basis for contract signing and subsequent cost control, making it an important component of project financial management.

Contingency Planning (Risk)

This step involves setting aside a dedicated budget to address fluctuations in material prices, changes in construction environments, design optimizations, transportation losses, and other unforeseen events. Engineering projects have lengthy cycles, during which various uncertainties may arise. Without prior planning, this can lead to budget overruns or schedule delays. Reasonably setting aside risk costs helps enhance project resilience and financial security, ensuring the ability to address unforeseen circumstances during construction and ultimately ensuring the project is completed smoothly and to a high standard.

Construction Drawing Preparation

This step involves converting conceptual designs and structural recommendations into detailed construction drawings, including structural layout, node details, component dimensions, and construction process descriptions. Accurate construction drawings not only provide a basis for factory processing and on-site installation but also offer critical data support for material procurement and cost control. Well-prepared drawings reduce construction errors, improve overall installation efficiency, and serve as a key technical safeguard for realizing design intent.

Material List Preparation

This step involves compiling a comprehensive material list based on the construction drawings, detailing the specifications, quantities, and supply requirements of all required materials. An accurate list facilitates rational procurement, inventory control, and optimized logistics planning, preventing material shortages or waste. Scientific material management effectively reduces costs, improves supply chain efficiency, and ensures smooth construction progress, making it a critical component of project material management.

Client Q&A

This step involves providing detailed answers and technical support to clients regarding design, construction, and budget-related issues. Through patient and professional communication, clients gain a better understanding of the content and technical requirements of each phase, enhancing their confidence in the overall project. Comprehensive client Q&A not only improves service quality but also reduces misunderstandings and disputes later on, ensuring the project proceeds efficiently and smoothly, making it a crucial step in building a good cooperative relationship.

Quotation Document Compilation

This step involves compiling and organizing cost data from all phases, including design, materials, labor, and management expenses, into a comprehensive and detailed quotation document. An accurate quotation document helps clients understand the project's overall investment requirements, facilitating decision-making and budget planning. A clear cost structure and technical terms reduce potential disputes later on, ensuring contract signing and smooth project execution, and serve as a crucial basis for advancing cooperation and implementing the project.

Submission of Quotation

This step involves formally submitting the complete quotation documents to the client and providing on-site or written explanations to ensure the client has a comprehensive understanding of the project content, costs, and implementation plan. During the submission process, key points such as the technical approach, schedule, and cost structure are emphasized to facilitate the client's comprehensive evaluation. A standardized quotation submission process not only demonstrates professional service standards but also promotes efficient communication between both parties, laying the foundation for subsequent contract signing and project implementation.