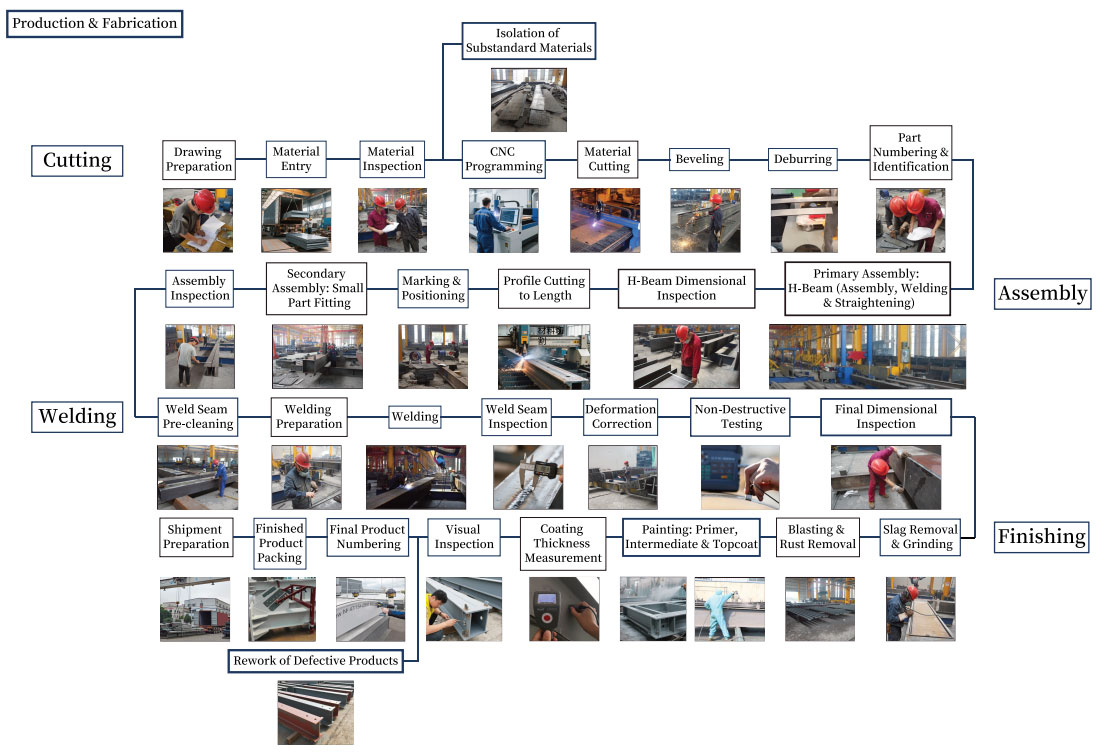

Production & Fabrication

Steel fabrication is the core process of transforming design drawings into high-quality structural components. It includes multiple stages such as material preparation, precision cutting, assembly welding, and finishing protection, emphasizing precise processing and strict quality control. Through CNC programming, non-destructive testing, systematic and standardized management, the accurate dimensions of components, stable welds, and uniform anti-corrosion coatings are ensured, providing solid guarantees for on-site installation. An efficient, rigorous manufacturing process ensures high-quality steel structures and on-time project delivery.

1. Cutting Stage

Drawing Preparation

This step is the process of further deepening and refining the design results into detailed processing drawings, parts drawings, and material specifications based on the construction drawings, and is a bridge between design and production. Through drawing preparation, complex three-dimensional structures, node connections, welding requirements, etc., can be converted into directly operable guidance documents to ensure that each profile, plate, bolt, etc., has clear dimensions, numbers, and process requirements. Accurate and complete drawings can not only ensure accurate component dimensions and clear nodes but also reduce processing errors, improve assembly accuracy, and minimize rework rates and material waste. In addition, a complete drawing system also provides an important basis for later quality inspection, on-site installation, and subsequent maintenance, and is a prerequisite for the smooth and efficient entire manufacturing process.

Material Entry

This step is an important link in formally receiving and storing the purchased steel and auxiliary materials into the factory warehouse, marking the official entry of the project into the substantive production stage. Material entry not only includes transportation, unloading, and placement, but also involves multiple procedures such as counting quantity, checking material specifications, checking surface quality, and measuring dimensional deviations. Through strict control, ensure that the materials meet the requirements of the design drawings and relevant standards, and lay a solid foundation for subsequent cutting, processing, and assembly. At the same time, reasonable planning of stacking locations and inventory management can effectively prevent material rust, deformation, and loss caused by chaotic stacking. Strict material entry procedures can also ensure construction progress, avoid delays due to unqualified or shortage materials, and reflect the company’s quality management level.

Material Inspection (Isolation of Substandard Materials)

This step is an important link for comprehensive quality inspection and performance verification of all incoming materials, which is directly related to the safety and durability of the entire project. The inspection content includes chemical composition analysis, mechanical property testing, dimensional accuracy inspection, and surface defect detection, etc., to ensure that steel, welding material, and other accessories meet the design and national standards. If unqualified products are found, they must be immediately isolated and marked, and the defect information must be recorded in detail to prevent them from entering the production process and burying hidden dangers. This not only protects the quality of subsequent processing and assembly but also effectively controls production costs and reduces rework losses. A complete, unqualified product management system reflects the company’s strict attitude towards quality control and is a key safeguard to ensure structural safety and enhance brand reputation.

CNC Programming

This step is a key link in using CAD and related software to convert detailed processing drawings into CNC programs that can be recognized by CNC cutting machines, drilling machines, or machining centers, and is an important manifestation of intelligent manufacturing. The program will set detailed parameters such as cutting path, cutting sequence, feed speed, cutti,ng angle and cutting thickness to ensure processing accuracy and consistency. Scientific CNC programming can not only improve material utilization, reduce cutting errors and the risk of secondary processing, but also greatly improve production efficiency and shorten the construction period. In addition, by optimizing the program, the energy consumption of the equipment and the wear of the tool can be reduced, and the service life of the machine can be extended. Fine programming ability reflects the technical strength of the enterprise and is the core foundation for realizing lean production and meeting the needs of high-quality engineering.

Material Cutting

This step is one of the core processes for high-precision segmentation of steel materials based on the compiled CNC program, using advanced technologies such as flame cutting, plasma cutting, or laser cutting. Material cutting not only requires accurate size and smooth cuts, but also must consider the cutting heat-affected zone, deformation control, and process residue issues to ensure the smooth progress of subsequent processes. The quality of cutting directly affects the assembly accuracy, welding effect, and final structural performance, so it is necessary to strictly control the cutting speed, temperature, and cutting path. Efficient and accurate cutting not only improves production efficiency and reduces waste generation but also maximizes material utilization and reduces costs. This step is also an important link to test the performance of production line equipment and the technical level of operators, and is an important guarantee for achieving high-quality steel structures.

Beveling

This step is to bevel the end face of the cut steel material to create good interface conditions for subsequent welding, ensuring that the weld can be fully filled and achieve sufficient strength and toughness. The shape, angle, and size of the groove must be strictly implemented under the drawings and process standards to achieve deep melting during welding, reduce defects such as pores, slag inclusions, and welding deformation. Good groove design can also improve welding efficiency, reduce welding material consumption and construction difficulty, and ensure the overall stability and load-bearing performance of the joint. In addition, groove processing is also the basis for structural reliability and long-term safety. It is one of the key technical links to improve the overall welding quality and ensure the durability of the project, reflecting the refinement and professionalism in the production process.

Deburring

This step is a necessary process for thoroughly grinding and removing burrs and flash remaining on the surface and edges of steel after cutting or beveling, aiming to improve the surface quality of components and the convenience of subsequent processing. If burrs are not cleaned in time, they may cause assembly errors and welding defects during welding and assembly, and even affect the overall beauty and durability of the structure. By using a grinder, grinder or special tools for detailed processing, the edges of the components can be ensured to be smooth and flat, the safety hazards caused by burrs can be reduced, and the safety of operators can be protected. Burr cleaning not only reflects the company’s meticulous pursuit of quality, but is also an important part of the quality control of the component appearance. It also has a positive impact on the subsequent anti-corrosion treatment and painting, and is an important guarantee for the delivery of high-standard finished products.

Part Numbering & Identification

This step is the process of uniquely numbering and identifying each processed component and part according to the design drawings. It is an important information management link to ensure the smooth progress of the project. Clear and standardized numbering can not only efficiently manage and classify components in the factory, reduce the confusion of warehousing and allocation, but also quickly locate and accurately assemble during on-site installation to avoid wrong installation and missing installation. Each number corresponds to specific component information, including specifications, dimensions, materials, process records, and inspection reports etc., which provides an important basis for later maintenance, inspection, and replacement. Numbering and identification are not only important evidence of production quality traceability, but also an effective means to improve project execution efficiency and ensure construction progress, reflecting the refinement level and professionalism of modern project management.

2. Assembly Stage

Primary Assembly: H-Beam (Assembly, Welding & Straightening)

This step is a comprehensive process of preliminary assembly in the steel structure workshop, precise welding, and deformation correction of the main load-bearing components. It is an important prerequisite for ensuring the stability of the overall frame and the smooth assembly of the subsequent structure. In this process, technicians will assemble and position large components such as steel beams and steel columns according to the requirements of the drawings, fix key nodes through high-strength welding, and then use hydraulic or mechanical equipment to adjust local deformations to keep the overall structure in the correct geometric dimensions and design angles. The correction stage is particularly important, as it can effectively control the distortion and warping of components and ensure construction quality and safety. This step not only has extremely high requirements for processing accuracy, but also tests the welding process and the experience of the construction team. It is a solid foundation for ensuring the smooth assembly of subsequent details.

H-Beam Dimensional Inspection

This step is a key link for comprehensive size inspection and geometric shape verification of the assembled H-beam components, which directly affects the overall accuracy of the structure and the smoothness of the subsequent on-site installation. The inspection contents include the length, width, height, flange and web thickness, angle, diagonal size, node position, and overall flatness of the components. All measurement results must strictly comply with the design drawings and relevant specifications. Through precision measuring tools and advanced equipment such as laser instruments, deviations can be discovered and corrected in time to prevent the accumulation of structural internal stress caused by difficulties in later on-site splicing or forced installation. Dimension inspection is not only an inspection of the factory processing quality, but also an important part of the entire project quality management system. It is one of the core steps to ensure the safety, durability, and aesthetics of the project.

Profile Cutting to Length

This step is an important process for accurately cutting various steel profiles to length according to the project design drawings and actual on-site installation requirements. It is the core link to improve the overall installation accuracy and construction efficiency. In the sizing process, the shrinkage of the weld seam of the component, the installation reserve, and the adaptation requirements of the later assembly must be fully considered to ensure accurate cutting dimensions and smooth cuts. Reasonable sizing can not only maximize material utilization, reduce residual waste and resource waste, but also reduce the risk of rework and construction delays caused by size mismatch. The quality of profile sizing directly affects the smoothness of subsequent splicing and the overall performance of the structure. It is an indispensable and important step in the entire steel structure processing process, reflecting the refined management of the construction organization and the high standards of detail control.

Marking & Positioning

This step is an important link for accurately marking the reference line and installation hole position on the surface of steel components or profiles. It is an accurate basis for subsequent welding, drilling, and overall assembly. By using laser line projectors, steel rulers, special marking tools, and other equipment, according to the detailed size requirements of the design drawings, the installation baseline, hole center, welding boundary, and other key control points are accurately marked on the components. Scientific and rigorous marking and positioning can significantly reduce subsequent assembly errors, improve overall assembly efficiency and structural accuracy, and avoid overall deviations or installation failures due to error accumulation. The marking process requires not only the operator to be highly concentrated and meticulous, but also to have a comprehensive understanding of the overall geometric shape and process flow of the component. It is a basic guarantee step to achieve high-quality and high-standard construction.

Secondary Assembly: Small Part Fitting

This step is the link of systematic assembly and positioning of small components, connecting plates, supports, and auxiliary components in steel structures, and is an important part of improving the overall structure. At this stage, technicians will accurately assemble various small connecting parts to the designated positions according to the previous markings, and fix them by welding or bolting to form a complete pre-assembled unit. Secondary assembly not only improves the details and additional functions of the components but also provides convenience for on-site hoisting and rapid splicing, reducing on-site operation time and safety risks. All connections must be strictly implemented under the requirements of the specifications to ensure that the connection is firm, the layout is reasonable, and the appearance is beautiful. This step is a functional supplement to the main components, reflecting the high standards of factory prefabrication and the advanced concept of modular construction.

Assembly Inspection

This step is a link for comprehensive quality inspection and verification of the assembled steel components, which is an important guarantee to ensure the safety of subsequent construction and the compliance of structural performance. The inspection content includes overall size, key node position, weld quality, flatness, verticality, hole position accuracy, etc. All parameters must comply with the design drawings and national industry standards. By using a variety of inspection tools such as total stations, steel rulers, and weld flaw detectors, technicians will record the inspection data in detail, discover and correct potential problems promptly, and prevent defective components from entering the on-site installation stage. Assembly inspection is not only a reconfirmation of processing quality, but also a key link in construction risk control. It can effectively improve the overall reliability and long-term durability of the structure, and is one of the important steps to reflect the rigorous construction and quality management level.

3. Welding Stage

Weld Seam Pre-cleaning

This step is to thoroughly clean the surface of all parts to be welded to ensure the formation of high-quality and stable welds during the welding process. Cleaning includes removing surface oxide scale, oil, rust, moisture, dust, and other impurities to prevent defects such as pores, slag inclusions, and unfused welds during welding. Common cleaning methods include grinding, sandblasting, chemical cleaning, and mechanical removal. During the operation, it is necessary to ensure that the surface cleanliness after cleaning meets the process standards and design requirements. High-quality weld pre-cleaning can not only improve the density and strength of the weld but also reduce the rework rate and later maintenance costs. It is an important pre-process to ensure the overall safety of the structure and extend its service life. This step reflects the rigorous attitude towards quality control and is an indispensable basic link in the manufacture of high-quality steel structures.

Welding Preparation

This step is a key step to complete equipment commissioning, welding material preparation, and welding process parameter confirmation in advance according to the project welding process requirements to ensure that the welding process can be carried out smoothly and efficiently. Welding preparation includes confirming the accuracy of parameters such as welding current, voltage, welding speed, preheating temperature, interlayer temperature, and performing equipment performance testing to ensure that all machines are in the best condition. At the same time, it is also necessary to explain the process technology to the welder and clarify the welding sequence, precautions, and quality standards. Adequate welding preparation can reduce welding defects, ensure the strength and appearance of the weld, and improve the overall performance and later durability of the component. This link not only tests the factory’s management specifications and technical level, but also reflects the rigorous and responsible attitude towards each process, and is the primary guarantee for welding quality control.

Welding

This step is to firmly connect different steel components through manual arc welding, submerged arc automatic welding, or gas shielded welding, so as to achieve the core process of integrated molding of each component. During the welding process, the determined process parameters must be strictly followed, and the current, voltage, welding speed, and interlayer temperature must be accurately controlled to ensure that the weld is full and uniform without defects such as cracks, pores, or slag inclusions. Welding is not only a guarantee of mechanical properties, but also related to the integrity and safety of the entire structural system. High-quality welding can effectively improve the bearing capacity and seismic performance of components, and also help the smooth progress of subsequent construction and maintenance work. This step requires extremely high skill levels for welders. It is one of the most critical and technical stages in the entire production process, and directly determines the quality performance of the final product.

Weld Seam Inspection

This step is an important link for detailed appearance inspection and quality confirmation of all completed welds to ensure that the welding meets the design and specification requirements. The inspection content includes the weld formation, uniformity, and whether there are cracks, pores, slag inclusions, incomplete penetration, and other defects on the surface. During the inspection process, visual inspection and special measuring tools such as weld rulers and magnifying glasses are usually combined to accurately measure the weld size, undercut, and weld height. If problems are found in time, they can be repaired or polished in the factory to prevent the defective components from entering the next process or construction site. Weld inspection is an effective verification of the implementation of welding processes and operating specifications, and is a necessary guarantee to ensure the safety of the structure and long-term reliability. This step not only reflects the strict control of construction details but also demonstrates the professionalism of the company in pursuing high-quality engineering.

Deformation Correction

This step is to correct and adjust the deformation of components caused by heat input during welding. It is an important means to ensure the accuracy of structural dimensions and geometric shapes. The thermal effect of welding will inevitably cause the components to warp, twist, or shorten. If not corrected in time, it will seriously affect the accuracy of subsequent assembly and installation, and even endanger the safety of the overall structure. Correction methods include flame correction, mechanical correction, and local pressurization, which need to be reasonably selected according to the type of component, degree of deformation, and material properties. Accurate correction can not only restore the size and shape required by the design, but also improve the subsequent construction efficiency and the smoothness of on-site assembly, and reduce rework and modification during the installation stage. This step requires a high technical level and experience of the operator, and is an important guarantee for achieving high-quality steel structure production and ensuring the project is delivered on schedule.

Non-Destructive Testing

This step is to detect internal defects in key parts, load-bearing nodes, and important connections after welding is completed. The purpose is to ensure that there are no hidden dangers in the internal quality of the weld and improve the safety and durability of the overall structure. Commonly used detection methods include ultrasonic testing, radiographic testing, magnetic particle testing, and penetration testing, each of which can detect different types of hidden defects, such as cracks, pores, slag inclusions, or unfused components. Nondestructive testing does not destroy the appearance and overall performance of the component. It is fast, accurate, and comprehensive. It is an important technical measure for quality control of modern steel structure projects. The test results will form a detailed report as an important basis for project quality files. This step reflects the high attention paid to project safety and is an important technical guarantee link to ensure the long-term reliability of the structure, improve the quality of the project, and enhance customer trust.

Final Dimensional Inspection

This step is an important link to strictly inspect the final size, shape, and overall geometric accuracy of steel components that have completed all processing and welding, ensuring that the components fully meet the requirements of the design drawings. The inspection contents include length, width, height, thickness, diagonal size, hole position accuracy, flatness, verticality, and other aspects. By using advanced measuring tools such as laser measuring instruments in steel structure workshop building, total stations, precision rulers, etc., the data is confirmed to be accurate item by item. Accurate dimensional inspection can not only effectively ensure the rapid and smooth assembly of components at the construction site, avoid dislocation, deformation, or inability to install due to dimensional deviation, but also reduce the risk of subsequent rework and construction delays. This step is not only the last line of defense of the quality control system, but also the core guarantee to ensure the overall aesthetics, functionality, and safety of the project, reflecting the high pursuit of refined production management.

4. Finishing Stage

Slag Removal & Grinding

This step is an important step to clean the welding slag, remove the spatter, and polish the surface of the component after welding. It is a preparatory process to ensure the quality of subsequent anti-corrosion coating. A large amount of welding slag, spatter particles, and oxides will be generated during the welding process. If they are not completely removed, it may lead to reduced adhesion of the subsequent anti-corrosion coating, local peeling, or corrosion spread. Slag cleaning and grinding usually use mechanical grinding, manual electric grinding wheel, or special slag cleaning tools to ensure that the weld and adjacent areas are flat and smooth. Grinding can also improve the overall aesthetics of the component surface and reduce the cost of later inspection and maintenance. This step not only improves the overall quality of the component surface but also lays a solid foundation for the subsequent sandblasting and rust removal, and painting. It is an important guarantee for achieving high-quality steel structure products.

Blasting & Rust Removal

This step is to use high-pressure sandblasting equipment to spray abrasives such as corundum, steel sand, or quartz sand at high speed onto the surface of the component to completely remove oxide scale, rust, oil, and other impurities. It is an important prelude to anti-corrosion treatment. Sandblasting can not only significantly improve the roughness of the component surface and enhance the mechanical adhesion of the subsequent coating, but also remove the tiny defects hidden in the surface and improve the overall protective performance. The surface of the component after sandblasting presents a uniform and clean metallic luster, which meets the strict requirements of the coating process. This step has strict control standards for the construction environment, abrasive particle size, spray pressure, and speed. Any negligence may affect the later anti-corrosion effect and aesthetics. Rust removal and sandblasting are one of key links to ensure the long-term corrosion resistance of steel structures, extend service life, and ensure the quality of the project.

Painting: Primer, Intermediate & Topcoat

This step is an important link for multi-level spray protection of components in accordance with anti-corrosion design requirements and process standards, including three main processes: primer, intermediate paint, and topcoat. Primer, as the first line of defense against corrosion, has excellent adhesion and sealing performance; intermediate paint is used to increase the coating thickness, enhance the barrier effect, and improve the overall protective performance; topcoat provides weather resistance and aesthetic effects, while preventing external erosion such as ultraviolet rays, rain, and snow. Each coat must be uniform, without defects such as missing coating, sagging, and bubbles. Scientific and reasonable multi-layer spray painting not only significantly improves the aesthetics of the components but also effectively extends the service life of the steel structure and reduces maintenance costs. This step is one of the core processes to achieve high anti-corrosion standards and reflect the level of refined management of construction technology.

Coating Thickness Measurement

This step is a key process for measuring the thickness and quality verification of the protective coating after spraying, ensuring that each paint film is uniform, up to standard, and meets the design and technical specifications. The detection usually uses a magnetic or eddy current thickness gauge to perform multi-point measurements on different parts and record the thickness distribution to prevent the degradation of anti-corrosion performance due to excessively thin local coatings, or cracking, sagging, and other quality problems due to excessive thickness. Paint film thickness detection not only verifies the accuracy of the coating process but also provides a reliable data basis for subsequent acceptance and long-term maintenance. It is one of the core technical measures to control the protective performance of steel structures. Through strict testing, it can ensure that the overall coating achieves the best protective effect, improve the durability and aesthetics of the structure, and fully guarantee the quality of the project and long-term safety performance.

Visual Inspection (Rework of Defective Products)

This step is to conduct a comprehensive appearance quality inspection of the spraying and the surface of the overall component, and it is an important link to timely discover and deal with various flaws or defects. The inspection content includes surface flatness, color consistency, paint film integrity, no sagging, no bubbles, no pinholes, no mechanical damage, etc., to ensure that the overall visual effect and functional performance meet the standards at the same time. If unqualified parts are found, they need to be reworked immediately, re-cleaned, re-sprayed, or repaired until they meet the design standard requirements. Strict appearance inspection is not only an important part of quality control, but also a strong guarantee for improving corporate reputation and enhancing customer satisfaction. Through a complete inspection and rework process, the cost of subsequent on-site correction and maintenance can be significantly reduced, which is an important guarantee step to ensure the final quality of the finished product and achieve high-standard delivery.

Final Product Numbering

This step is an important process for uniquely numbering and registering information for each steel component that has been processed and passed the inspection. It is a prerequisite for the efficient execution of later logistics management and on-site installation. Each number not only contains the specific size, material, weight, and drawing number of the component, but also records detailed information such as production, inspection, and spraying, which is convenient for subsequent traceability and technical support. By standardizing the numbering, it is possible to avoid mixing, wrong installation, and missing installation on site, greatly improving construction efficiency and accuracy. The numbering information is usually marked in a conspicuous position and is used in conjunction with QR codes and signs to achieve digital information management. This step not only reflects the level of systematic production management but also provides a strong basis for later project acceptance, maintenance, and replacement, and is an important part of high-quality delivery of steel structures.

Finished Product Packing

This step is a necessary measure to scientifically and reasonably package and protect steel components that have passed various tests to ensure that they are protected from physical damage, corrosion, and pollution during transportation, loading and unloading, and storage. The packaging method needs to be reinforced and packaged with a variety of materials such as wooden boxes, steel belts, plastic films, or anti-corrosion cloth according to the size, weight, and shape characteristics of the components. Reasonable packaging can not only effectively prevent the components from bumping and deformation, but also prevent moisture and dust, and ensure the coating and surface quality. During the packaging process, the number, weight, and stacking order of each component must be recorded in detail to ensure smooth and efficient on-site unloading and installation operations. This step is not only an important guarantee for ensuring the intact delivery of components, but also one of the core links that reflects the company’s strict control of details and attention to the quality of the entire project cycle.

Shipment Preparation

This step is to arrange the whole process of logistics transportation of steel components from the factory to the construction site, and is an important link to achieve a smooth construction connection. The specific content includes preparing a detailed shipping list according to the project schedule, confirming the shipping batch, quantity, component specifications, and numbers, reasonably arranging vehicles and routes, optimizing the loading sequence, and avoiding damage or loss of components during transportation. Shipping preparation also requires coordination of on-site reception conditions, notifying the project party in advance to prepare for loading and unloading, and ensuring that the goods can be sorted and installed quickly and accurately after arrival. Efficient and scientific shipping preparation not only guarantees the overall progress of the project and reduces logistics risks, but also improves the efficiency of construction site management. It is a key link to achieve rapid assembly, ensure construction quality and safety, and fully demonstrates the professional service level and responsibility of XTD Steel Structure as a global leading one-stop prefabricated steel structure company.