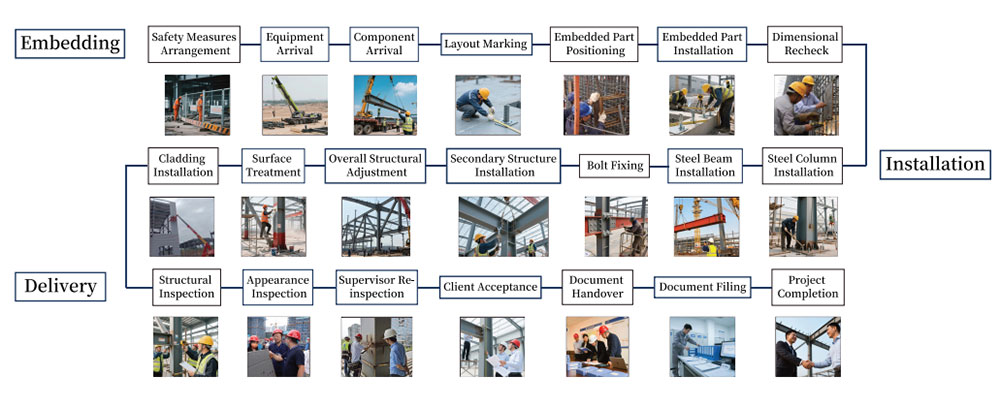

The on-site construction is the core process of steel structure projects, from component transportation to installation completion. Through the arrangement of embedded parts, installation of steel columns and steel beams, connection reinforcement, and enclosure structure construction, the overall safety and stability of the structure are ensured. Scientific construction organization, safety measures, and on-site management ensure the progress and quality of construction. During the delivery stage, multiple inspections and customer acceptance are carried out to ensure that the project results meet the design and use requirements and complete the perfect closed loop from manufacturing to application.

1. Embedded Stage

Safety Measures Arrangement

This step is the process of fully deploying safety protection facilities at the construction site, which is the primary task to ensure the safety of personnel, equipment, and the overall working environment. The arrangement of safety measures includes installing safety fences, setting up eye-catching warning signs, hanging safety warning banners, demarcating dangerous working areas and prohibited areas for non-operating personnel, and equipping high-altitude operations with anti-fall devices. In addition, fire extinguishers, protective nets, guardrails, emergency passages, and first aid equipment are required to ensure rapid response in emergencies. The scientific planning and meticulous implementation of safety measures will help prevent accidents such as falling from heights, mechanical collisions, and object strikes, and maintain on-site order and the physical and mental health of construction personnel. This step is not only a rigid requirement of laws and regulations, but also reflects the company's high attention to construction quality, progress and personnel life safety, and is a solid foundation for the smooth advancement of subsequent processes.

Equipment Arrival

This step is an important preparatory link for the orderly delivery of large-scale mechanical equipment and auxiliary construction tools required for the project to the site according to the construction plan, marking that the construction work is about to enter the substantive operation stage. The equipment on-site involves hoisting machinery (such as tower cranes, crawler cranes), welding machines, power tools, testing instruments and temporary power supply facilities, etc., which must be unloaded, positioned, assembled, and debugged under the guidance of professional technicians to ensure that the performance of each equipment is normal and the operation is safe and reliable. The full preparation of equipment can not only greatly improve the operation efficiency and reduce construction delays, but also reduce safety risks and improve the construction quality and stability. This step requires the construction unit to have meticulous organization and coordination capabilities and strict equipment management processes. It is an important prerequisite for the efficient implementation of subsequent steel component hoisting, positioning, welding and other processes, and it is also the core embodiment of the company's technical strength and on-site management capabilities.

Component Arrival

This step is a key preparation link for transporting the steel structure components completed according to the factory manufacturing plan to the construction site in sequence and placing them reasonably according to the project sequence and spatial layout. The components entering the site need to be strictly checked for number, size and appearance quality to ensure that they meet the transportation and stacking requirements, and prevent delays in later installation due to confusion or errors in the components. Scientific and orderly component stacking not only optimizes the utilization of on-site space and avoids blocking the construction channel, but also reduces the frequency of hoisting and movement, and improves the overall construction efficiency. In this step, component protection measures must also be considered to prevent moisture, rust, or mechanical damage to ensure that they are in the best condition before hoisting. The entry of components is not only an important part of construction material management, but also a bridge connecting factory production and on-site installation. It reflects the overall progress control and refined management level of the project, and is the basic condition for ensuring the smooth progress of the project as scheduled.

Layout Marking

This step is the link between precise measurement and marking at the construction site, which is the basic operation to ensure the accuracy of subsequent steel structure installation. Laying out the lines requires the use of total stations, laser rangefinders, levels, and other measuring tools based on the data of the design drawings to accurately mark key reference points, axes, component center lines, elevation control points, etc., one by one at the construction site. Through high-precision laying out, the horizontal position, verticality, and overall spatial layout of the components can be effectively controlled to avoid dimensional deviation and accumulated errors during the subsequent installation process. This step also requires multiple reviews and cross-checking of the layout results to ensure data consistency and clear markings. Accurate laying out not only provides a reliable basis for steel structure installation but also lays a solid foundation for subsequent processes such as hoisting, splicing, welding, and node assembly. It is an important guarantee for ensuring the safety, functionality and aesthetics of the engineering structure.

Embedded Part Positioning

This step is a delicate operation linked to accurately positioning and placing embedded parts in the concrete foundation or floor slab according to the structural design drawings and construction specifications. It is an important guarantee for the precision control of steel structure installation. Embedded parts mainly bear the connection function between the later steel components and the foundation. Their position deviation will directly affect the stability and force performance of the superstructure. During positioning, the center line, elevation, horizontality, verticality, etc. must be strictly measured and corrected to ensure that they are completely consistent with the subsequent installation axis. This step usually uses a variety of methods such as steel bar positioning, support fixation and temporary welding to maintain a precise position to prevent offset during concrete pouring. Accurate positioning of embedded parts can effectively improve the overall installation efficiency, reduce rework and adjustment, ensure structural safety and smooth construction, and is one of the important links for the smooth implementation of steel structure projects.

Embedded Part Installation

This step is an important step to firmly fix the embedded parts that have been accurately positioned in the concrete foundation or other structures, and is the basic guarantee for the later installation of steel structures. During the installation process, the elevation, horizontality and verticality of the embedded parts need to be strictly controlled according to the design requirements. Welding, bolt fixing, temporary support and other methods are usually used to ensure their stability. During construction, care should be taken to avoid position displacement, loosening or tilting during concrete pouring and vibration to ensure its bearing function in the structure and later connection strength. Reasonable installation of embedded parts not only helps the precise docking of subsequent steel components and improves the overall assembly efficiency, but also reduces rework costs and construction delays. This step is a key process that reflects the rigor of construction, technical level and quality control capabilities, and is a necessary prerequisite for ensuring the long-term safety and reliability of the engineering structure and the smooth progress of construction.

Dimensional Recheck

This step is an important process for the comprehensive measurement and verification of the embedded parts that have been installed. It is the final confirmation link to ensure the overall installation accuracy and construction quality of the steel structure. The verification content includes the center position, elevation, plane position, horizontality, verticality, etc., of the embedded parts to ensure that they are completely consistent with the design drawings to avoid subsequent connection problems or structural dislocations caused by installation deviations. By using advanced detection tools such as total stations, laser rangefinders, and precision levels, the review work can be completed efficiently and accurately. When deviations are found during the dimensional review, adjustments, repair welding or correction measures should be taken immediately to prevent the accumulation of errors from affecting the overall project progress and safety. This step is not only an important part of the quality management system, but also the core guarantee to ensure the smooth lifting, rapid splicing and final structural stability of subsequent steel components. It is an important step that is indispensable for high-standard and high-quality construction.

2. Installation Stage

Steel Column Installation

This step is to hoist the main load-bearing steel columns prefabricated in the factory to the embedded parts through large lifting equipment, and accurately position and fix them. It is the key link of the "erecting skeleton" of the entire steel structure building. During construction, the verticality, elevation and centerline deviation of the steel columns must be strictly controlled to ensure that the geometric accuracy of the overall frame is consistent with the design. In order to prevent the steel columns from tilting or shaking during installation, temporary support or cable fixation is usually performed first, and then bolt or weld connection reinforcement is performed. As the longitudinal force-bearing core of the entire structure, the installation quality of the steel column directly affects the accurate installation and overall stability of the upper steel beams and other components, and is the basic guarantee for subsequent safety performance, durability, and seismic performance. This step requires highly skilled operators and perfect equipment configuration, and is an important part of the refinement of the project and high-standard construction management.

Steel Beam Installation

This step is to accurately hoist the transverse steel beams to the top or node position of the installed steel columns according to the design requirements, and complete the connection by bolts or welding, thereby forming the main horizontal load-bearing structure of the overall frame system. The installation of steel beams requires precise measurement according to the laying-out benchmark, controlling the gap and height difference of the beam ends, ensuring that each node is stable and reliable, and ensuring the mechanical properties and stability of the structure as a whole. During the installation process, it is also necessary to adjust the horizontality and straightness of the beam in real time, and take temporary support measures to prevent deformation or accidental displacement during construction. Scientific and rigorous steel beam installation not only improves the overall rigidity and bearing capacity of the structure, but also lays a solid foundation for the construction ofthe roof, floor structure, and subsequent secondary structure. This step is an important link in connecting the main skeleton in steel structure engineering, which is directly related to the safety, functionality and durability of the building.

Bolt Fixing

This step is to use high-strength bolts to reliably connect steel columns, steel beams and other key components to form a stable structural system, which is an indispensable core link in the installation of steel structures. The bolt fixing process needs to strictly control the bolt specifications, quantity, preload and installation sequence according to the design standards to ensure that the nodes can effectively withstand various design loads. High-strength bolt connections can not only transmit and disperse mechanical stress, but also have a certain degree of detachability, which is convenient for later structural inspection and maintenance. This step is usually combined with a torque wrench or tensioning equipment to apply force accurately to prevent structural deformation or bolt loosening due to insufficient tightening or overtightening. The standardized operation of bolt fixing significantly improves the safety and overall reliability of the structure. It is an important link that reflects the construction accuracy and process level of steel structure engineering, and plays a decisive role in ensuring the subsequent construction progress and engineering quality.

Secondary Structure Installation

This step is an important process for installing secondary components such as purlins, support rods, secondary beams, ceiling frames, and floor decking. It is a necessary step to improve the overall structural system and realize functional space separation and support. Although the secondary structure does not bear the main load, it plays an important role in ensuring the overall stiffness, stability, wind resistance, and seismic resistance of the building. During the installation process, precise positioning and connection must be carried out strictly per the design drawings to prevent accumulated errors or affect the performance of the main structure. Reasonable secondary structure layout not only enhances the integrity of the building but also provides necessary support for the exterior system, pipeline layout, and later decoration. The successful completion of this step will help improve the overall construction efficiency and building aesthetics. It is an important link to achieve functional perfection, safety and reliability, and spatial comfort. It is a key transition from "frame" to "space".

Overall Structural Adjustment

This step is to complete the overall assembly of the main structure and the secondary structure, fully realize the spatial formation and functional layout of the main building, and is an important node in the steel structure installation project. At this stage, the steel columns, steel beams, support systems and secondary structures need to be systematically integrated to ensure overall stability, seismic performance and rational force. During the installation process, the node connection quality, geometric dimension deviation, and overall verticality and flatness must be strictly controlled, and multi-point synchronous monitoring must be performed through measuring equipment to ensure frame accuracy. After the overall structure is installed, a comprehensive structural acceptance and stability test can be carried out to ensure that it meets the design and specification requirements. This step marks the basic formation of the main project, which is a key link to provide basic conditions for the subsequent enclosure system, electromechanical system, and indoor and outdoor decoration construction. High-quality overall structural installation not only ensures the safety and durability of the building, but also lays the foundation for the smooth progress of the project in the later stage.

Surface Treatment

This step is to conduct a detailed appearance inspection, deviation adjustment and surface repair of the overall installed steel structure to ensure that the overall quality and visual effect of the building meet the expected standards. The inspection content includes the verticality, flatness, connection node integrity, coating integrity and whether there are mechanical damage, deformation and other problems. For the defects found, timely repair, adjustment or secondary treatment, such as welding, grinding, re-spraying, etc., is required to ensure that the surface of the structure is uniform, beautiful and has good anti-corrosion performance. High-quality appearance treatment can not only improve the overall beauty and market image of the building, but also effectively extend the service life of the components and reduce the cost of later maintenance. This step reflects the strict control of engineering details and overall quality, and is a key link to improve customer satisfaction, enhance the value of the building and demonstrate the professional ability of the enterprise.

Cladding Installation

This step is the process of installing the enclosure system such as exterior wall panels, roof panels, doors and windows, curtain walls, etc. on the main steel structure according to the design drawings. It is an important link to achieve the functional integrity and overall performance of the building. The enclosure structure not only serves to enclose the building space and resist the invasion of external environment such as wind, rain and snow, but also directly affects the building's thermal insulation, heat insulation, sound insulation and energy-saving effects. During the installation process, the size of the panels, the density of the joints, and the waterproof and windproof properties must be strictly controlled to ensure a beautiful appearance and perfect functions. A reasonable enclosure layout can also optimize the comfort of the building's internal space and improve the overall energy-saving performance. This step is the key node for the transformation of the building from a "frame" to a "practical space", reflecting the combination of architectural technology and aesthetics, and is also the final stage for achieving the overall function, appearance and durability of the building.

3. Delivery Stage

Structural Inspection

This step is an important part of the comprehensive and systematic dimensional accuracy, node quality and overall mechanical performance inspection of the completed steel structure, and is the core measure to ensure the quality and safety of the project. The inspection content includes the geometric dimensions of the components, the overall verticality, the node deviation, the weld quality and the bolt connection strength, etc., and is strictly carried out by the design drawings and relevant construction specifications. To ensure the accuracy of the inspection, advanced equipment such as laser measuring instruments, total stations, and ultrasonic flaw detectors is usually equipped to conduct non-destructive inspections on key connection parts. When problems are found, they should be recorded and rectified in time to prevent the accumulation of hidden dangers. Structural inspection is not only a comprehensive inspection of construction technology and quality control, but also a key step to ensure that the building has safety, stability and durability in the subsequent use stage. It is the core link to achieve long-term performance assurance of the building.

Appearance Inspection

This step is the process of carefully inspecting the outer surface of the steel structure, mainly checking the coating uniformity, anti-corrosion treatment quality, component surface flatness, color difference, weld appearance, and whether there are mechanical damage, rust, sagging and other defects. Appearance inspection is not only related to the overall aesthetics of the building and the first impression of customers, but also affects the later protection performance and maintenance costs. This link is usually combined with manual visual inspection, tool measurement and local grinding inspection, and is carried out in strict accordance with the construction and coating technical standards. Any problems found need to be repaired, re-sprayed or polished to ensure that the design and contract requirements are met at the final delivery. Appearance inspection is an important manifestation of the refinement of project construction and the control of details. It is an important link to enhance customer satisfaction and establish brand image. It is also a "facade" control step for the quality of construction projects.

Supervisor Re-inspection

This step is a re-verification of the quality, safety and technical standards of steel structures after construction by an independent third-party supervision unit. It is an important link to ensure that the project meets the contract, specifications and design requirements. The supervision re-inspection not only conducts random inspections on technical indicators such as structural dimensions, weld quality, and node connections, but also conducts a comprehensive inspection of construction site safety measures, process execution, and inspection record integrity. With professional technical capabilities and objective positions, the supervision unit puts forward rectification opinions on possible quality risks and supervises the implementation of rectification to ensure the final delivery quality of the project. The successful completion of this link is not only a verification of the construction level of the construction company, but also provides a solid foundation for subsequent customer acceptance. Supervision re-inspection reflects the core requirements of transparent and standardized management of construction projects, and is an indispensable and important part of project completion acceptance.

Client Acceptance

This step is to invite representatives of the owner unit (customer) to the construction site to conduct a comprehensive review and confirmation of the project completion, which is the most critical human review link in the entire project delivery process. During the acceptance process, the customer will check the project quality, dimensional accuracy, appearance effect, function realization and construction data item by item to ensure that the building fully complies with the design contract and functional requirements. The project team needs to prepare a complete acceptance report, quality inspection records and rectification situation description in advance, and arrange detailed on-site explanations. If the customer proposes rectification opinions, they should be corrected and confirmed again in time. Only after the customer acceptance is passed, the project can officially enter the completion and handover stage. This step is not only the recognition of the final results of the project, but also related to the subsequent maintenance, warranty and user experience. It is a key link to establish customer trust, maintain cooperative relationships and enhance brand reputation.

Document Handover

This step is an important link to systematically organize and formally hand over various types of data formed throughout the project to the customer, which is one of the core contents of the life cycle management of construction projects. The handover materials include design drawings, construction records, material inspection reports, weld inspection reports, hidden engineering records, construction change records, completion drawings and various quality assurance documents. The completeness and accuracy of the handover of materials not only help customers with later management, repair and maintenance, but also provide a legal basis for future transformation, expansion and responsibility tracing. This step usually requires the preparation of a detailed list and electronic backup, and the signatures and confirmations of both parties to ensure that the information is handed over correctly. Standardized data handover shows that the company attaches great importance to quality management and service responsibilities, and is an important guarantee for establishing a good corporate image, protecting customer rights and interests, and ensuring the safety of subsequent project use.

Document Filing

This step is to systematically organize, number and preserve all project-related documents, data, image materials and acceptance records for a long time, which is an important part of the company's internal quality management and project management. The content of the file archiving includes contract documents, design change records, construction materials at various stages, quality inspection reports, supervision reports, customer acceptance documents and related photos, etc., to ensure that they can be quickly and accurately found and retrieved when needed in the future. A perfect archiving system not only provides valuable resources for enterprises to accumulate technical information and summarize construction experience, but also provides a basis for responsibility tracing, quality accident handling, and later technical support. This step reflects the standardized and scientific management level of the enterprise. It is the core support link for continuously improving the quality of project delivery, improving operational management efficiency, and supporting long-term business development. It is also a landmark step for enterprises to achieve lean management.

Project Completion

This step marks the successful completion of the entire steel structure project from design, manufacturing, installation, to inspection and acceptance, and officially enters the owner's use and maintenance stage. An important milestone. At this time, all activities on the construction site are basically evacuated, the fence is removed, the site is cleaned up, the information and certificates are complete, and it has passed the double acceptance of the customer and the supervisor. The completion of the project is not only the ultimate embodiment of the construction quality but also represents the full fulfillment of the contractual responsibilities, demonstrating the comprehensive strength and execution of the enterprise. At this stage, project summaries and experience feedback will also be conducted to form the basis for internal learning and improvement. After the project is completed, the customer will officially receive the building and put it into use, and the company will also enter the warranty service period and continue to assume the responsibility of after-sales service and technical support. This step is not only the end of a project, but also the beginning of our cooperation with you as a leader in the industry, brand accumulation and word-of-mouth communication.