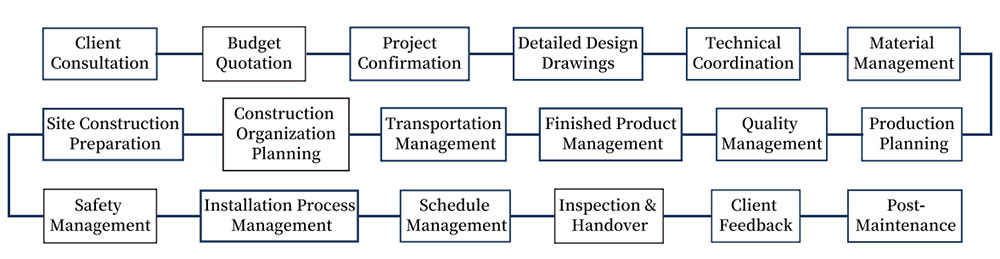

The project management runs through the entire life cycle of steel structure projects, involving customer communication, cost budgeting, quality control, schedule planning and safety assurance. Through systematic management processes and scientific planning arrangements, we ensure efficient connection of all links, control risks and meet customer needs. Perfect project management not only improves construction efficiency and project quality but also enhances customer satisfaction and subsequent maintenance services and promotes successful project delivery and continuous operation.

Client Consultation

This step is to communicate in depth with customers, fully understand their project needs, budgets, expected functions and special requirements, and conduct a preliminary analysis of site conditions, building uses, etc. Through professional technical consultation and patient answers, we help customers clarify the overall planning direction, optimize design ideas, and reduce the cost of later modifications. This process not only lays the foundation for project cooperation but also reflects the company's service awareness and professional strength, enhances customer trust and satisfaction, and is the first step to ensure the smooth progress and successful implementation of the project.

Budget Quotation

This step is to scientifically formulate a detailed budget and quotation plan based on customer needs, design plans and market material prices, combined with construction technology and engineering volume. Accurate quotations can not only allow customers to clearly understand the investment costs and the composition of various expenses, avoid disputes caused by insufficient funds or overspending in the future, and also lay the foundation for the signing of the contract between the two parties. A reasonable and transparent budget plan enhances customer trust while ensuring construction quality and progress, which is an important prerequisite for the smooth start of the project.

Project Confirmation

This step is to formally start the project management process, clarify the project goals, plans, organizational structure, and the division of responsibilities of various departments and positions. Through project establishment, a complete management system and implementation plan are established, and human, material and technical resources are reasonably allocated to ensure that the overall work is carried out in an orderly manner. At this stage, it is also necessary to predict risks and design prevention and control measures to provide organizational guarantees for subsequent design, construction, and acceptance. Scientific and effective project establishment is a key link to ensure that the project is smoothly promoted according to the expected goals.

Detailed Design Drawings

This step is to comprehensively optimize and refine the structure, nodes, connections and construction details based on the preliminary concept design, and generate complete drawings that meet construction needs. Deepening the design not only solves the technical problems in the actual component processing but also improves the operability and efficiency of production, and reduces product deviations and material waste. Detailed and complete drawings provide a scientific basis for subsequent technical disclosure, processing and on-site installation, and are the core steps to ensure the quality and smooth implementation of the project.

Technical Coordination

This step is to explain the drawings and technical requirements in detail to the production and construction personnel of the project department, and clarify various technical standards, key processes, precautions, and quality control points. Through comprehensive and systematic technical disclosure, we can unify the understanding of construction, reduce incorrect construction and rework caused by misunderstandings, and ensure the safety and progress of production. Technical disclosure also enhances personnel's understanding of the overall project goals and improves team execution, which is an important link to ensure production quality.

Material Management

This step is to purchase, inspect, store and distribute all kinds of materials required for the project to ensure timely supply, accurate quantity and qualified quality. Scientific material management can effectively control costs, avoid waste and backlogs, and ensure the continuity and safety of the construction process. Through strict material planning and inventory control, improving construction efficiency and reducing procurement risks are important basic links to ensure the smooth progress of the project and controllable costs.

Production Planning

This step is to scientifically and rationally prepare production and processing plans based on the project schedule and construction resources, and clarify the tasks, completion time and required resource allocation of each stage. Reasonable plans help coordinate the connection between factory processing and on-site construction, reduce process conflicts, and improve overall production and construction efficiency. Through dynamic adjustment and tracking, ensuring that components are completed on time and with high quality, providing strong guarantees for project progress, is the core measure to promote the precise execution of the project.

Quality Management

This step is to establish and implement a strict quality control system throughout the entire process from material procurement, processing and production to on-site installation. By formulating inspection standards, implementing intermediate process monitoring, organizing special inspections, etc., quality hazards are discovered and corrected promptly to ensure that the project meets the design and specification requirements. Strict quality management not only prevents safety accidents and reduces maintenance costs, but also enhances customer trust and brand image, and is a key guarantee for ensuring the long-term performance and safety of the project.

Finished Product Management

This step is to number, quality inspect, store and transport the completed steel components out of the factory to ensure that all components remain intact during transportation and on-site installation. By formulating scientific warehousing, stacking and protection measures, we can reduce the risk of damage, misdelivery and mixed loading, and ensure that every finished product is used accurately and on the construction site as planned. Standardized finished product management is an important part of ensuring construction quality, improving installation efficiency and reducing overall costs.

Transportation Management

This step is to reasonably organize the transportation of components from the factory to the construction site according to project requirements, including transportation plan formulation, route optimization, loading and unloading arrangements and on-site reception. Scientific transportation management not only ensures that components are delivered on time and safely, but also prevents construction from being affected by damaged components, but also effectively reducing transportation costs and potential risks. Through refined scheduling and full-process tracking, ensuring the smooth progress of the project is an important support link for achieving efficient construction organization.

Construction Organization Planning

This step is to systematically organize and arrange the entire construction process, including staffing, construction process sequence, equipment deployment and safety protection measures. A scientific and complete construction organization plan helps to improve construction efficiency, reasonably allocate resources, and reduce construction delays and safety accidents. By clarifying the work plan and division of responsibilities at each stage, achieving efficient and orderly construction site management, providing a solid foundation for achieving project goals and quality requirements, is an important prerequisite for ensuring the smooth implementation of the project.

Site Construction Preparation

This step is to make comprehensive preparations for the construction site, including site cleaning, material stacking planning, safety protection facilities construction, construction machinery entry and operator training. Adequate site preparation helps to ensure smooth construction, reduce safety risks and operational obstacles, and improve overall work efficiency and quality. Through planning and detailed arrangements, ensuring that the construction environment meets technical and safety requirements is a prerequisite for ensuring the smooth start and high-quality advancement of the project.

Safety Management

This step is to establish and improve the construction safety management system, formulate safety operating procedures, carry out safety education and training and risk investigation, and ensure the safety of people and property at the construction site. Through strict daily inspections and special inspections, hidden dangers can be eliminated promptly to prevent all kinds of accidents. Effective safety management not only protects the safety of workers' lives, but also enhances the company's reputation and project image. It is the basic guarantee for achieving high-quality construction and sustainable development.

Installation Process Management

This step is to formulate detailed process flow and construction standards for the steel structure installation stage, and strictly regulate each operation link and quality control requirements. By strengthening on-site monitoring and operation guidance, ensure that the component connection is accurate, the node is firm, and the overall structural stability meets the design requirements. Scientific installation process management can not only reduce rework and quality risks, improve construction efficiency and safety, but also is an important guarantee link to reflect the company's construction technology level and engineering quality.

Schedule Management

This step is to continuously track, monitor and adjust the actual progress of each construction stage according to the overall construction plan to ensure that the project's node targets are completed on schedule. By formulating a detailed timetable, resource allocation and dynamic correction measures, coordinate personnel, equipment and materials to prevent delays and schedule conflicts. Scientific and effective progress management can improve overall construction efficiency and execution, and is an important management means to ensure the smooth completion of the project, control costs and fulfill contract commitments.

Inspection & Handover

This step is to organize a comprehensive quality, function and quantity inspection of the completed project to ensure that the requirements specified in the design and contract are met. During the acceptance process, it is necessary to prepare an acceptance report, deal with rectification issues, complete relevant procedures, and finally confirm the project handover. The standardized acceptance and delivery process is not only a formal sign of project closure, but also an important manifestation of customer satisfaction. It is a key step to establish long-term cooperative relationships, ensure post-maintenance services and consolidate corporate reputation.

Client Feedback

This step is to systematically collect customer evaluations, suggestions and improvement opinions on the entire project process, and comprehensively evaluate the effectiveness of project implementation and customer satisfaction. By establishing an effective feedback mechanism, service or technical shortcomings can be discovered on time, promoting the company to continuously optimize products and services, and enhance customer experience and brand influence. Actively listening to and responding to customer feedback helps to deepen cooperative trust and open up future cooperation opportunities. It is an important source of power to promote corporate progress and innovation.

Post-Maintenance

This step is to provide customers with post-maintenance plans, maintenance guidance and technical support services for completed projects to ensure the long-term safety and performance of the structure. Through regular inspections, maintenance suggestions and emergency response services, the risks of building operations are reduced, the service life is extended, and the subsequent costs are reduced. Perfect follow-up maintenance not only reflects the company's responsibility but also enhances customers' confidence in the quality of the project. It is an important link in strengthening brand value and enhancing market competitiveness.