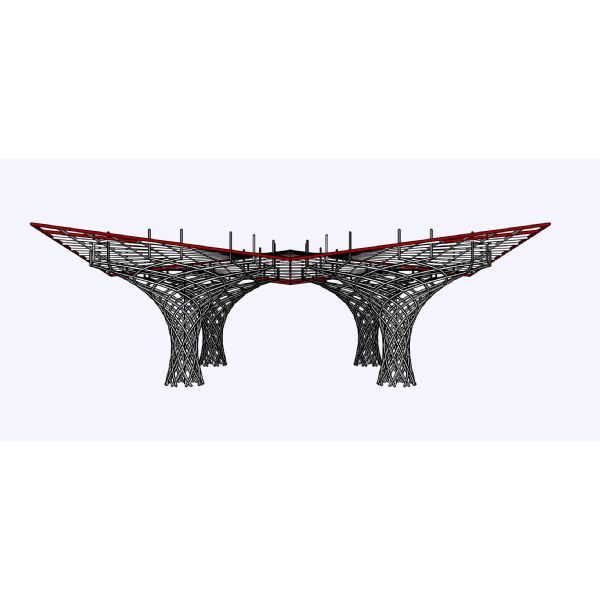

3D Render

Product Advantages

Special-shaped truss structure advantages include lightweight construction, rational load distribution, and high material utilization, significantly enhancing structural stability while reducing costs. It also offers excellent seismic performance and construction flexibility, facilitating factory prefabrication and rapid on-site assembly, thereby effectively shortening construction schedules and improving construction quality. It is widely applied in projects requiring large spaces or unique exterior designs, such as sports arenas, exhibition halls, convention centers, high-speed rail stations, airport terminals, and large-scale commercial complexes, particularly suited for scenarios emphasizing spatial expressiveness and architectural imagery.

- Ultra-lightweight construction: Special-shaped space truss structure, through its rigid three-dimensional structure, withstands loads in various directions, significantly reducing overall weight. Each steel component conforms to the mechanical design, forming an efficient stress transmission network. This construction significantly reduces the building’s deadweight while optimizing the foundation’s bearing capacity, making it particularly suitable for use in complex geological conditions or for the renovation of existing buildings. Its lightweight nature also reduces material and transportation energy consumption, embracing the concept of green construction from the ground up. In load-sensitive projects such as large transportation hubs, this advantage translates into significant savings in foundation treatment costs and a substantial reduction in construction schedules.

- Ultra-large span column-free space: This structure transcends the span limitations of traditional beam-column systems, achieving cross-regional load redistribution through rational design. Rigid joints combine to form a complete load-bearing system, effectively mitigating the risk of localized collapse. The column-free design unleashes a full building plan, meeting the core functional requirements of stadiums for viewing events and exhibition centers for flexible layout. The highly adaptable spatial trusses support unique roof forms such as domes and cantilevers, creating a breathable, flowing spatial experience in environments that emphasize spatial transparency, such as airport terminals.

- Exceptional stability assurance: Spatial grid structure provides sufficient rigidity to withstand all-around lateral tensile stresses, significantly suppressing wind-induced vibration and thermal stress deformation. Rigidity enhancements at the joints effectively slow the progression of localized instability and failure. This stability advantage is crucial for construction in coastal typhoon-prone areas and high-intensity seismic zones, ensuring the full-cycle structural safety of crowded venues such as airport terminals and stadiums. Structural deformation monitoring data during the operation and maintenance phase continuously verifies the reliability of its stability performance.

- Excellent seismic performance: Earthquake energy is absorbed and dissipated by the three-dimensional structure, preventing damage caused by stress concentration. Targeted joint construction guides stress transfer in a predetermined pattern, significantly extending the building’s lifespan. In vital projects such as high-speed rail stations and data centers, this performance ensures continuous equipment operation and significantly reduces the risk of collapse caused by environmental disasters. In short, seismic design is deeply integrated into the structural design, meeting the most stringent seismic fortification requirements without the need for additional damping devices.

- Efficient construction efficiency: A factory-prefabricated system based on modular design diagrams ensures millimeter-level machining accuracy for members and joints. A coding system helps on-site assembly workers quickly locate required components and simultaneously integrates pre-buried pipelines with equipment foundations. High-strength connection techniques eliminate the risks of high-altitude welding, significantly improving schedule control for tight construction deadlines such as large commercial complexes. Prefabrication significantly reduces noise and dust on the construction site, aligning with green construction standards in urban core areas and creating a win-win for customers, both economically and socially.

- Adaptability of Diverse Designs: The highly scalable design of the special-shaped space truss structure eliminates the conflict between structural form and architectural creativity. Components can be arranged along any spatial curve, precisely achieving complex parametrically designed surfaces. In cultural venues and landmark commercial buildings, the structural framework itself becomes a vehicle for spatial aesthetic expression. A diverse selection of materials, including steel, aluminum alloy, and composite materials, combined with customized surface treatments, truly realizes the cutting-edge design concept of “structure as decoration,” injecting iconic artistic DNA into the city skyline.

Product Parameters

| Material Standard: | AISI, ASTM, BS, DIN, GB, JIS | Steel: | Q235B (commonly used carbon structural steel, suitable for general construction use) | ||

| Q355B (commonly used carbon structural steel, suitable for general construction use) | |||||

| 45# (suitable for components with high strength requirements) | |||||

| 40Cr (alloy structural steel, suitable for parts bearing heavy loads) | |||||

| Country of origin: | China | Certification: | CE (European Union Standard) | ||

| GB (Chinese National Standard) | |||||

| ISO9001 (International Quality Management System Certification) | |||||

| AWS (American Welding Society Certification) | |||||

| Surface treatment: | Primer/Intermediate/Topcoat (color and coating thickness can be customized according to customer needs) | Material Thickness Tolerance: | ±0.5 | ||

| Hot-dip galvanizing (superior corrosion resistance, suitable for harsh environments) | |||||

| Service scope: | Prefabricated Buildings | Wall & Roof Panels: | Steel plate/FRP plate (customized by customers) | ||

| Life: | 50 years | Paint coating: | Provide a variety of colors and coatings according to design requirements. | ||

| Wind resistance: | 12 levels | Shock resistance: | 8 levels | ||

| Quantity (square meters) | 1 – 2000 | 2001 – 5000 | 5001 – 10000 | >10000 | |

| Estimated time (days) | 26 | 35 | 43 | To be negotiated | |

| Service scope: | Design consultation, node deepening, construction plan, installation guidance | ||||

| Pricing method: | One price, no price increase in the middle, transparent price, a nd avoid hidden fees. | ||||

Special Space Truss Structure Technical Specifications

To ensure that we can provide a more accurate quotation and preliminary design, we recommend that you provide the following as much information as possible:

- Building appearance: shape, size, and height

- Material standards: Conform to ISO/ASTM/CE/GB standard certification for materials. Steel generally uses Q235B and Q355B. Special customization is available upon request.

- Building use: such as industrial plants, warehouses, offices, etc., so that we can reasonably recommend roofing and wall materials

- Load requirements: including live load, snow load, wind load, etc. If there are specific design standards or special usage requirements, please indicate them in advance.

- Coating standards: Through the coating standard certification in ISO/ASTM/CE/GB, we have stringent requirements on the protective performance and environmental adaptability of the coating, its compatibility, and its adhesion durability.

- Delivery Standard: Complying with the standard certification of products in ISO/AWS D1.1/CE/GB, we always provide customers with high-quality services.

It is not a concern if the above data cannot be provided temporarily. We will make a preliminary plan for you based on the conventional parameters and further optimize the design in subsequent communication.

Quote Information

Support customized design, welcome to provide drawings for quotation.

Whether you have drawings or not, we welcome cooperation and can provide you with a professional quotation within 1 working day.

- Existing drawings

Please send us your design drawings, and we can provide one-stop service from processing and production, logistics, and delivery to installation guidance. With advanced production technology, complete testing equipment, and a complete technical system, we always provide customers with high-quality and competitive steel structure products.

- No drawings yet

Our design team is experienced and can customize light steel structure buildings according to your needs, including but not limited to gymnasiums, warehouses, workshops, industrial park buildings, halls, and dome building systems.

Professional design team to meet diverse needs

We have a high-level design team that can tailor steel structure solutions according to different project types and customer requirements. To provide more accurate quotations and design solutions, please provide the much information as possible: building purpose, size, load requirements, local standards, etc.

Delivery site photos

|

|

| Delivery of Steel Structure Components (Container Packing) | Delivery of Steel Structure in Sections (Loose Parts) |

|

|

| Delivery of Steel Structure Combinations (Mixed Method) | Delivery of Steel Structure Modular Products (Assembled and Packaged in Units) |

Special Space Truss Structure Application

- Sports Arena

The sports arena emphasizes overall structural tension and column-free viewing space, with a span generally ranging from 60 to 100 meters and a floor area of 20,000 to 50,000 square meters. The special-shaped space truss structure achieves efficient load transfer through a two-way spatial grid topology, with its outstanding load-bearing efficiency and bending resistance eliminating the risk of vibration associated with traditional cantilever structures. The lightweight system significantly reduces the self-weight of the roof structure, and combined with seismic isolation bearings, effectively suppresses high-frequency vibrations caused by crowd movements during events. The double-curvature grid design, coupled with acoustic reflection simulation, precisely optimizes sound wave propagation paths to eliminate echo interference.

Curved glass curtain walls are integrated with the truss upper chords, and natural light is refracted twice through structural components to create uniform lighting. This technology enables the basketball arena to break through the limits of viewing distance, while the swimming center achieves column-free coverage of the diving platform area, creating an immersive event experience for spectators while meeting the millimeter-level deformation control requirements for ultra-high-definition broadcasting.

- Exhibition Hall

Exhibition hall architectural requirements focus on spatial flexibility and exhibition adaptability, with spans typically ranging from 30 to 60 meters and areas of approximately 10,000 to 30,000 square meters. The special-shaped truss structure for irregular spaces employs a variable topological node system, ensuring that truss units can be freely reconfigured according to exhibition requirements. Node connection reliability enables standard exhibition zone boundaries to be reconfigured within 90 minutes, while high-strength aluminum alloy members ensure single-point suspension capacity meets the demands of large-scale art installations.

Parametric surface algorithms optimize the roof structure, while gradient perforation rates balance natural light intensity and UV protection. The truss lower chords integrate sliding rail power supply modules, supporting dynamic adjustments to the exhibition lighting system. In automotive exhibition halls, this achieves a 10-meter clear height column-free space, while in science and technology exhibition halls, it creates a seamless acoustic environment throughout the facility, enabling exhibition narratives to transcend physical boundary constraints.

- Exhibition Center

Exhibition center steel buildings must balance large-scale coverage with multifunctional conversion, often spanning 40 to 70 meters and covering 30,000 to 60,000 square meters. The special-shaped truss structure for irregular spaces employs a cable-supported dome system, with prestressed cable nets enhancing the overall stiffness of the large-span roof. Overall stiffness achieves deflection control of less than 3‰ at the mid-span, while local stability is maintained through diagonal grids to resist asymmetric exhibition loads.

Lightweight, high-strength materials enable 7-meter cantilevered meeting rooms without additional support, and wind vibration control technology mitigates the risk of roof uplift in high-wind areas. Fluid dynamics-inspired curved surfaces guide airflow to create a negative pressure zone beneath the roof, reducing air conditioning energy consumption by over 30%. The main hall of the international summit achieves a 200-meter-long uninterrupted space while meeting the sound field uniformity requirements for a thousand-person banquet hall, enabling a seamless transition between international conferences and luxury exhibitions within 48 hours.

- High-Speed Rail Station (Steel Structure Infrastructure)

High-speed rail station architecture emphasizes iconic design and large-span spaces, typically spanning 50 to 80 meters with areas ranging from 20,000 to 40,000 square meters. The special-shaped space truss structure offers superior stability and seismic performance. Lightweight materials reduce foundation pressure, while the streamlined roof design enhances visual transparency, optimizing passenger flow and waiting experiences.

- Airport Terminals

Airport terminals are designed to ensure efficient operations while maintaining a clear sense of space. They typically span 60 to 100 meters and cover a total area of 50,000 to 100,000 square meters. A unique space-frame structure addresses the deformation challenges of very long boarding bridges and can withstand the impact of thousands of aircraft taking off and landing daily. Safety in extreme weather conditions is also considered, with key locations designed to absorb and disperse forces to resist damage. The lightweight design allows the terminal to be column-free for nearly 80 meters, creating a spacious waiting area.

The hyperbolic roof features a distributed solar film and concealed rainwater recycling pipes. Intelligent shading devices adjust light and temperature based on flight schedules, and special devices at the bridge joints reduce vibration caused by taxiing aircraft. This results in a largely column-free check-in area. The unique node design has become a landmark of the city’s air gateway, improving passenger travel efficiency by approximately 40% compared to traditional designs.

- Large-Scale Commercial Complexes

Large-scale commercial complexes emphasize spatial interaction and a vibrant retail atmosphere. They typically span 40 to 70 meters and have a total floor area between 30,000 and 80,000 square meters. Their unique spatial design allows for three-dimensional, circular corridors between different levels, with a central atrium extending 70 meters for unobstructed views. The lightweight structure allows for large, open retail display areas while maintaining safety even when crowded. The roof utilizes an air membrane with adjustable transparency, coupled with an intelligent light-guiding system, allowing the interior light to more closely mimic the rhythm of nature.

Multimedia display walls and projection equipment are integrated into the building’s structure, transforming the space into an immersive experience. In the atriums of large shopping malls, trusses support suspended art installations, while cross-floor escalators and light and shadow effects create distinct atmospheres throughout the day and night. These enhanced spatial experiences have increased customer dwell time by 25%, and brand turnover and construction cycles have been reduced to one-third of traditional methods.