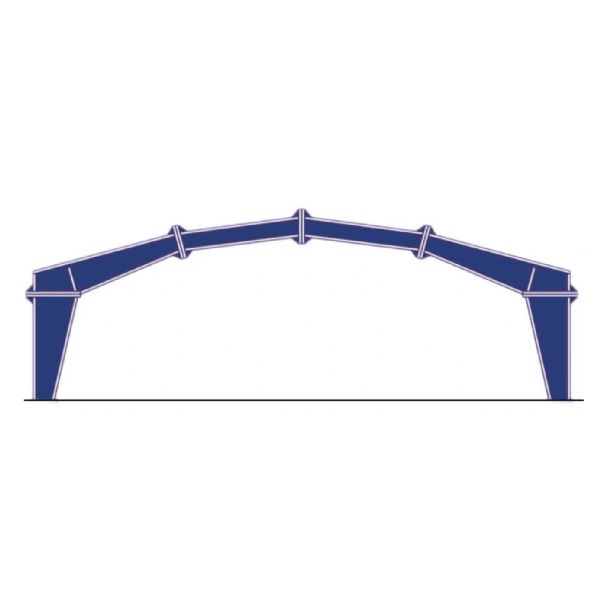

Standardized Rigid Portal Frame 3D Render

Product Advantages

Standardized rigid portal steel frames’ advantages lie in their simple structure, clear load-bearing characteristics, and high degree of component standardization, significantly improving material utilization rates and reducing design and construction costs. It also offers excellent fire resistance, corrosion resistance, and construction convenience, facilitating factory-based mass production and on-site high-efficiency assembly, effectively ensuring engineering quality and shortening construction schedules. It is widely applied in industrial plants, logistics warehouses, agricultural greenhouses, storage centers, and other projects requiring large, regular spaces with high sensitivity to construction efficiency. It is particularly suitable for industrialized building scenarios emphasizing practicality, cost-effectiveness, and rapid delivery.

- Standardized rigid portal steel frames Design: The standardized portal steel frame adopts a rigorous modular design system that transforms the common needs of industrial buildings into repeatable structural units. Its core advantage lies in using predefined parameters (such as span gradients, eave height gradients, and load levels), which allow different customer requirements to be addressed with proven design solutions. While the standardized process may seem restrictive, in reality, mature technical solutions—such as fixed end plate thickness, bolt arrangements, and stiffener layouts—ensure both structural safety and construction feasibility. As a result, the design is naturally compatible with industrialized production lines, avoiding the cost risks caused by unconventional designs or human error. Moreover, standardized unit combinations can achieve efficient layouts for single factories and support large-scale replication for industrial parks, delivering both functional efficiency and an aesthetic sense of order. Its forward-looking approach is also reflected in reserved installation interfaces, where standardized nodes are compatible with future building upgrades and modifications.

- Lightweight Construction: The standardized portal steel frame uses high-strength hot-rolled H-beams combined with precise variable cross-section designs, ensuring material distribution matches load demands. Simply put, thicker sections are used where forces are greater, while lighter sections are applied where loads are smaller, achieving both safety and material savings. Compared with concrete structures, this steel structure is much lighter, reducing foundation pressure significantly, which makes it suitable even for sites with weaker soil conditions. Lightweight construction offers two additional advantages: prefabricated standardized components are easier to transport, and installation requires only small lifting equipment instead of large cranes. On-site assembly is simplified, as all bolt holes are precision-drilled in the factory, making the process similar to assembling building blocks—no longer dependent on high welding skills or favorable site conditions. More importantly, these structures can be dismantled and reused after their service life, enabling recycling and maximum utilization of resources.

- Superior Rigidity Performance: In a standardized portal frame, beams and columns are firmly connected by end plates and high-strength bolts, while column bases resist horizontal forces through shear keys and anchor bolts, ensuring stability and preventing lateral displacement. The sloped roof design not only aids drainage but also works together with purlins and cladding panels to form a box-like system that enhances wind resistance. Lightweight high-strength steel can absorb seismic energy through local deformation rather than sudden fracture, improving earthquake safety. This structural system has been proven across countless factories, with unified standards for elements such as knee braces, column-top stiffeners, and connection details, ensuring consistent safety in every building. The roof slope also channels wind and snow away, preventing accumulation and keeping the building secure under extreme weather.

- Rapid Assembly: The modular assembly method turns construction into an on-site integration process similar to industrial manufacturing. All standardized product components undergo punching, cutting, welding, and anti-corrosion treatment on digital production lines, shifting quality control from the construction site to the factory floor. On-site, assembly speed improves significantly: anchor bolts are first positioned, steel columns are erected and aligned, main beams are quickly bolted in place, and roof purlins are clipped into position. Each step connects seamlessly like an assembly line. Traditional welding is replaced by high-strength bolts, eliminating fire hazards and allowing construction to continue even in rainy or snowy conditions. More efficiently, the main structure and cladding systems can be installed simultaneously: once purlin holes are precisely aligned, roof panels can be fixed immediately, while wall framing locks into preset column interfaces. Thanks to this deep integration of modularization and rapid assembly, large-scale industrial parks that once took half a year to build can now be completed in just a few months, drastically reducing time costs and accelerating investment returns to meet modern industry’s stringent time requirements.

- Adaptability to Diverse Scenarios: The greatest value of the standardized system lies in its universality and adaptability, making it suitable for a wide range of industrial applications. For example, column spacing between 6–12 meters can meet the needs of light assembly workshops, while larger cross-sections easily support heavy equipment facilities. The regular column grid is ideal for automated logistics systems, and column-free large spaces enable flexible production line layouts. Modular unit design supports both vertical stacking for multi-level warehouses and horizontal extension for large continuous workshops. Even more importantly, standardized interfaces make expansion and system integration easy: reserved slots in steel columns allow direct installation of solar panel supports; roof purlin nodes connect to ventilation ducts; electrical cable trays can be embedded directly into beams. What were once “heavy” factory buildings have now become adaptable “living organisms”—as enterprises grow, additional units can be seamlessly added; as industries upgrade, prefabricated interfaces allow new smart systems to be integrated. From agricultural markets to semiconductor clean rooms, this standardized and modular steel structure system, with its diversity and adaptability, is becoming the solid spatial foundation of modern industrial development.

Product Parameters

| Material Standard: | AISI, ASTM, BS, DIN, GB, JIS | Steel: | Q235B (commonly used carbon structural steel, suitable for general construction use) | ||

| Q355B (commonly used carbon structural steel, suitable for general construction use) | |||||

| 45# (suitable for components with high strength requirements) | |||||

| 40Cr (alloy structural steel, suitable for parts bearing heavy loads) | |||||

| Country of origin: | China | Certification: | CE (European Union Standard) | ||

| GB (Chinese National Standard) | |||||

| ISO9001 (International Quality Management System Certification) | |||||

| AWS (American Welding Society Certification) | |||||

| Surface treatment: | Primer/Intermediate/Topcoat (color and coating thickness can be customized according to customer needs) | Material Thickness Tolerance: | ±0.5 | ||

| Hot-dip galvanizing (superior corrosion resistance, suitable for harsh environments) | |||||

| Service scope: | Prefabricated Buildings | Wall & Roof Panels: | Steel plate/FRP plate (customized by customers) | ||

| Life: | 50 years | Paint coating: | Provide a variety of colors and coatings according to design requirements. | ||

| Wind resistance: | 12 levels | Shock resistance: | 8 levels | ||

| Quantity (square meters) | 1 – 2000 | 2001 – 5000 | 5001 – 10000 | >10000 | |

| Estimated time (days) | 26 | 35 | 43 | To be negotiated | |

| Service scope: | Design consultation, node deepening, construction plan, installation guidance | ||||

| Pricing method: | One price, no price increase in the middle, transparent price, a nd avoid hidden fees. | ||||

Standardized rigid portal steel frames Specifications

To ensure that we can provide a more accurate quotation and preliminary design, we recommend that you provide the following as much information as possible:

- Building appearance: shape, size, and height

- Material standards: Conform to ISO/ASTM/CE/GB standard certification for materials. Steel generally uses Q235B and Q355B. Special customization is available upon request.

- Building use: such as industrial plants, warehouses, offices, etc., so that we can reasonably recommend roofing and wall materials

- Load requirements: including live load, snow load, wind load, etc. If there are specific design standards or special usage requirements, please indicate them in advance.

- Coating standards: Through the coating standard certification in ISO/ASTM/CE/GB, we have stringent requirements on the protective performance and environmental adaptability of the coating, its compatibility, and its adhesion durability.

- Delivery Standard: Complying with the standard certification of products in ISO/AWS D1.1/CE/GB, we always provide customers with high-quality services.

It is not a concern if the above data cannot be provided temporarily. We will make a preliminary plan for you based on the conventional parameters and further optimize the design in subsequent communication.

Quote Information for Standardized Rigid Portal Frame

Support customized design, welcome to provide drawings for quotation.

Whether you have drawings or not, we welcome cooperation and can provide you with a professional quotation within 1 working day.

- Existing drawings

Please send us your design drawings, and we can provide one-stop service from processing and production, logistics, and delivery to installation guidance. With advanced production technology, complete testing equipment, and a complete technical system, we always provide customers with high-quality and competitive steel structure products.

- No drawings yet

Our design team is experienced and can customize light steel structure buildings according to your needs, including but not limited to gymnasiums, warehouses, workshops, industrial park buildings, halls, and dome building systems.

Professional design team to meet diverse needs

We have a high-level design team that can tailor steel structure solutions according to different project types and customer requirements. To provide more accurate quotations and design solutions, please provide the much information as possible: building purpose, size, load requirements, local standards, etc.

Delivery site photos

|

|

| Delivery of Steel Structure Components (Container Packing) | Delivery of Steel Structure in Sections (Loose Parts) |

|

|

| Delivery of Steel Structure Combinations (Mixed Method) | Delivery of Steel Structure Modular Products (Assembled and Packaged in Units) |

Standardized Rigid Portal Frame Application

- Industrial Factory

The most crucial requirement for industrial factories is a spacious space that allows for flexible production line layouts, unencumbered by internal columns. Standardized portal frames, as an advanced steel structural system, utilize a three-dimensional load-bearing design to evenly distribute forces throughout the entire frame. This eliminates the need for central support columns, allowing for greater flexibility in the layout of equipment and production lines. The lightweight yet strong steel not only reduces foundation pressure but also absorbs vibration energy during earthquakes by distributing and redistributing loads, enhancing seismic safety. The entire structure utilizes a modular design, with all components digitally modeled and pre-assembled in the factory. Upon transport to the site, the modular components can be directly hoisted and assembled.

Leveraging a BIM system, construction accuracy can be controlled to the millimeter level, allowing for the simultaneous installation of pipelines and equipment foundations, significantly reducing construction time. This modular steel structure construction method seamlessly integrates civil engineering and installation, enabling rapid commissioning of industrial projects and flexibly adapting to subsequent adjustments or upgrades to production lines.

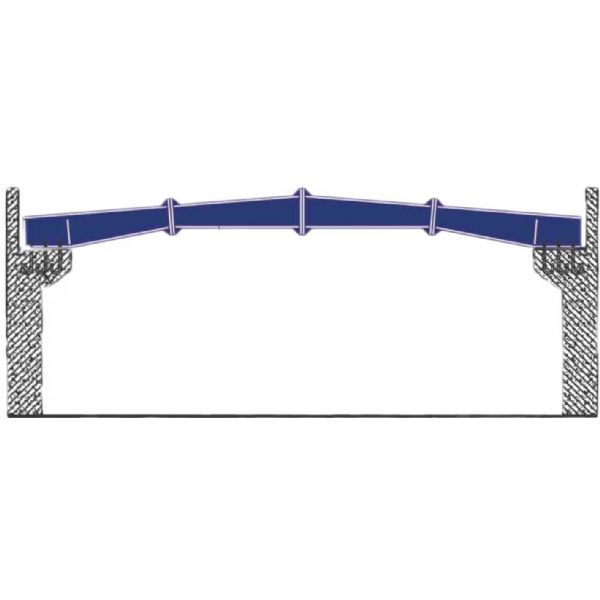

- Logistics Warehouses

The key to modern logistics warehouses is the optimal use of vertical space while ensuring smooth cargo transportation and circulation. As an advanced steel-frame building, the standardized portal frame, with its wide spans and curved roof design, offers exceptionally high internal clearance, freeing it from the constraints of traditional structures and allowing for taller racking. It is a typical form of steel-frame industrial building, boasting a lightweight yet sturdy main structure, coupled with high-strength joint connections.

This not only saves steel but also ensures long-term stability. All components are manufactured in the factory using standardized prefabricated units, treated for corrosion, quality tested, and then transported to the site for rapid assembly using efficient bolt connections. This allows for the simultaneous construction of the roof, walls, and equipment hangers, significantly shortening the construction cycle. Furthermore, the system incorporates modular expansion interfaces, allowing for easy expansion or modification of warehouses during future technological upgrades without requiring large-scale demolition, ensuring a flexible and advanced logistics system.

- Agricultural Greenhouses

The construction of agricultural greenhouses requires a delicate balance between structural performance and a favorable crop-growing environment. As a proven steel-frame building, the standardized portal frame, through its rational structural design, ensures uniform natural light throughout the roof and facades, preventing shadows from affecting crop growth. The frame is constructed of weather-resistant steel, resisting corrosion in high-humidity environments and ensuring the greenhouse’s long-term stability. The lightweight structure reduces foundation requirements and is suitable for a variety of geological conditions, effectively reducing infrastructure costs.

The innovative plug-in system allows even non-professionals to quickly assemble the greenhouse according to the blueprint, perfectly matching the crop growing cycle and saving valuable time. More importantly, the standardized connection points ensure the greenhouse’s scalability, allowing it to be expanded from a single unit to multiple units, maximizing land utilization. As a typical application of steel-frame industrial buildings, this type of greenhouse utilizes green construction methods throughout the entire process, minimizing environmental impact and ensuring a natural and sustainable agricultural production environment.

- Storage Centers

Modern warehouses require large spaces to support automated sorting systems. Standardized portal frames, as a type of steel-frame industrial building, feature a column-free, long-span design, allowing equipment to be freely positioned within the building. The lightweight and sturdy steel structural components conserve steel and resist wind vibration.

During construction, facilities such as fire protection piping, ventilation systems, and lighting can be pre-installed in the factory, allowing for rapid modular assembly on site, ensuring both safety and time savings. Large units can be hoisted into place in one go, avoiding the high risks of traditional high-altitude, bulk construction. Sensors can also be installed in the system to monitor the structural status in real time, providing long-term safety assurance for high-density steel-frame buildings while facilitating future expansion and renovation.