Structural Steel Bridge 3D Render

Product Advantages

Steel structure bridges possess excellent mechanical properties and a high strength-to-weight ratio, making them suitable for various complex loading conditions and terrain. Their advantages include: lightweight structure, facilitating transportation and installation; standardized components, suitable for factory prefabrication and rapid on-site assembly; short construction periods and high efficiency; and excellent seismic performance and durability. They are widely applied in urban expressways, highways, railway bridges, and river/sea crossings, particularly suited for modern bridge engineering projects that require simultaneous improvements in aesthetic design and structural performance.

1. Steel structure Box Girder Bridge

-

Extremely High Torsional Stiffness, Suitable for Complex Load Distributions

Steel box girder bridges, with their enclosed cross-section design, have extremely high torsional stiffness, making them particularly suitable for bridge structures that need to withstand eccentric loads and unevenly distributed loads. Compared to open cross-section structures, steel structure box girders can more effectively resist torsional deformation caused by concentrated vehicle loads or lateral wind forces, ensuring the stability and safety of traffic on the bridge deck. This advantage is particularly evident in multi-lane, two-way urban elevated or highway bridges. Additionally, steel structure box girders can further enhance lateral stiffness through multi-box combinations, meeting the engineering requirements for wider bridge decks and being widely applicable to modern high-intensity traffic scenarios.

-

Excellent Bridge Deck Continuity for a Smooth and Comfortable Driving Experience

Due to the excellent overall integrity and bridge deck continuity of steel box girders, they can achieve large-span continuous structural arrangements without the need for expansion joints, thereby effectively reducing structural deformation and maintenance work caused by temperature changes. Bridge deck continuity also means smoother vehicle travel on the bridge without a bouncing sensation, enhancing driving comfort and traffic safety. Additionally, the continuous structure facilitates uniform distribution of internal forces, significantly reducing local stress concentration on the bridge deck and effectively extending the structural service life. This advantage is particularly suitable for urban expressway systems and densely populated transportation hubs with high pedestrian and vehicle traffic.

-

Simple and Modern Design, Compatible with Urban Landscape Environments

Structural Steel Bridges feature smooth exterior lines and clean cross-sections, presenting a modern and minimalist visual aesthetic that harmoniously integrates with urban architecture and surrounding landscapes. Unlike the complex truss structures of traditional truss bridges, box girder bridges have a clear bridge body outline, making it easy to apply decorative treatments such as painting or cladding. This allows them to serve not only as transportation infrastructure but also as visual landmarks in the city. In projects such as urban elevated bridges and subway overpasses, steel box girder bridges can meet engineering functional requirements while also considering architectural aesthetics, making them an ideal choice for contemporary bridge design that seeks to unify structure and art.

-

Easy to Prefabricate in Factories, Improving Construction Efficiency

Steel box girder components are suitable for factory-based production, enabling high-precision, high-efficiency mass manufacturing. Through modern processes such as CNC cutting, automatic welding, and overall assembly, component dimensions are consistent, and weld quality is excellent, effectively reducing on-site construction errors. Additionally, box girder segments can be transported to the site for modular assembly, significantly shortening the construction schedule. This is particularly suitable for urban engineering projects with tight schedules or limited site conditions. In tasks such as bridge renovation or emergency nighttime construction, steel box girder bridges leverage their rapid construction advantages to significantly reduce impacts on traffic and the surrounding environment.

-

Excellent Structural Durability and Low Maintenance Costs

The enclosed internal space of steel structure box girder bridges facilitates the application of anti-corrosion coatings or the filling of desiccants, reducing the risk of long-term exposure to humidity and corrosive environments, and ensuring excellent durability. Their strong structural integrity minimizes the risk of cracks or fatigue failure, making them particularly suitable for regions with frequent storms and complex climates.

Additionally, maintenance access channels can be installed within the box structure for convenient post-construction inspections. Compared to other bridge types, steel structure box girder bridges require minimal maintenance, with longer intervals between inspections, resulting in lower operational costs and contributing to reduced lifecycle costs. For regions facing significant fiscal pressures or limited maintenance resources, steel box girder bridges offer a cost-effective solution.s

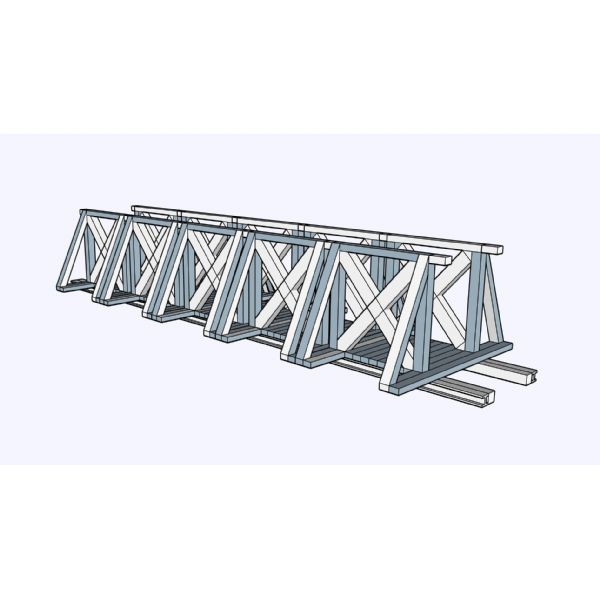

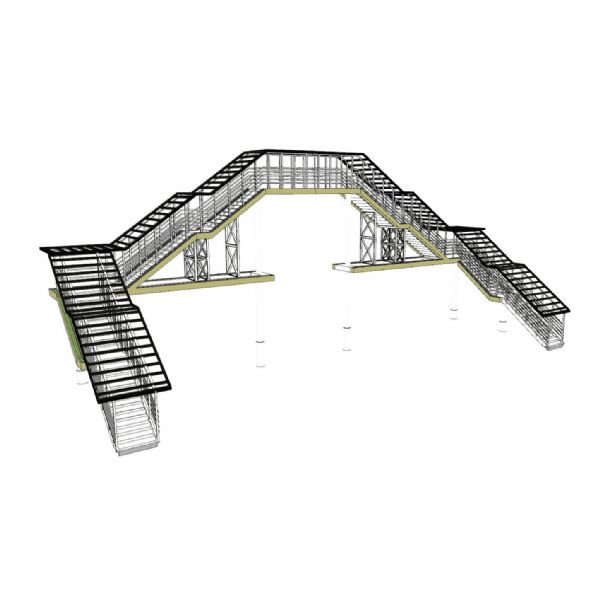

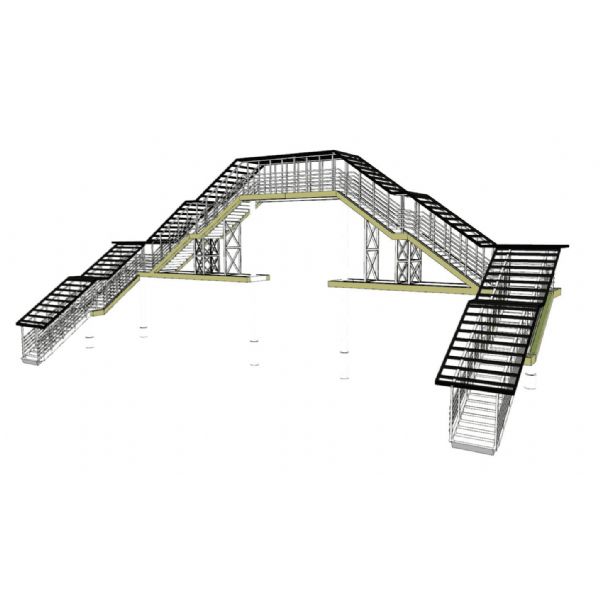

2. Steel Trus s Bridge

-

High Material Utilization and Clear Structural Force Transfer

Steel truss bridges are composed of triangular units formed by members connected at nodes, with each member primarily bearing axial forces rather than bending moments. This “structural mechanics matching material properties” feature significantly improves material utilization efficiency. Under the same span conditions, the total amount of steel structure required for a truss bridge is typically less than that of box girder or arch bridges. Moreover, the clear force transmission paths are conducive to accurate stress analysis and structural optimization. For projects with strict economic requirements, steel structure truss bridges are an ideal solution that balances structural efficiency and cost-effectiveness—particularly suitable for long-span and heavy-load applications.

-

Adaptability to Long Spans and Heavy Loads with Strong Load-Bearing Capacity

Due to the high geometric rigidity and overall stability of truss structures, steel truss bridges are especially suitable for long-span crossings such as railway bridges, highway bridges, and elevated urban overpasses. Under heavy loads, the truss structure distributes forces among multiple members, reducing stress concentration on individual components and thereby extending the service life of the bridge. Through the optimized arrangement of top chords, bottom chords, and web members, steel truss bridges can easily achieve unsupported spans of over 100 meters, and in some cases, extend beyond 200 meters. Their exceptional span capacity and adaptability to high loads make them the preferred bridge type for major transportation routes and valley crossings in mountainous regions.

-

Flexible Construction and Assembly for Complex Site Conditions

With a high degree of standardization, steel truss bridge components are well-suited for factory prefabrication and modular assembly on-site. They accommodate segmented erection and cantilever construction methods, making them particularly suitable for complex terrains, limited workspaces, or bridge projects over water bodies. Various construction techniques—such as falsework, incremental launching, or rotation methods—can be employed, greatly enhancing on-site adaptability. Additionally, the lightweight nature of truss structures reduces load demands on foundations and piers. Whether in dense urban zones or remote mountainous areas, steel truss bridges offer flexible responses to environmental constraints, ensuring construction safety and schedule control, making them a vital solution under challenging geological conditions.

-

Transparent and Aesthetic Structure with Strong Visual Identity

The structure of a steel truss bridge is transparent and visually clear, with a unique geometric beauty derived from its regular triangular configuration. While ensuring rational force distribution, this also imparts a strong visual identity to the bridge. Unlike the heavy appearance of enclosed structures, truss bridges appear lighter and more open, reducing the visual pressure on urban skylines or natural environments. Depending on design requirements, upper-deck, lower-deck, or through-type configurations can be flexibly selected, and further enhanced with lighting, coatings, or other landscape elements. As a result, steel truss bridges are widely used in urban areas and scenic spots where transportation and landmark functions must be integrated.

-

Convenient Inspection and Maintenance with Optimized Lifecycle Management

The primary components of truss bridges are exposed, making regular inspections, flaw detection, and fatigue crack monitoring straightforward and efficient. Compared with enclosed structures, the open design of steel truss bridges reduces maintenance blind spots and difficulties, significantly improving operation and maintenance efficiency. Moreover, component replacement and local repairs are more convenient, helping to reduce long-term maintenance costs. As lifecycle management becomes increasingly emphasized in bridge design, steel truss bridges—owing to their excellent maintainability and modular nature—offer sustainable guarantees for the safe and economical operation of bridges throughout their service lives.

3. Steel structure Arch Bridge

-

Arch Structures Are Naturally Suited to Compression, Offering Stable and Efficient Load-Bearing

Steel structure arch bridges take advantage of the inherent mechanical characteristics of the arch form, transmitting the majority of loads as axial compressive forces to the abutments. This provides the structure with exceptional load-bearing capacity and stability. Compared to girder bridges—which primarily rely on bending resistance—arch bridges are more adept at bearing vertical loads and maintain excellent structural performance even over large spans, making them suitable for a wide range of complex geological or support conditions.

Especially in scenarios where the foundations on both sides are sound but mid-span construction is challenging, steel arch bridges offer a high-strength, low-deformation solution. Their “compression-dominant with supplementary bending and shear” load transfer mechanism reflects optimized structural logic, making them a classic choice for river or valley crossings.

-

Elegant Arch Profile with Strong Aesthetic and Landmark Value

With their curved form, steel arch bridges possess strong visual impact and architectural beauty, blending naturally into urban landscapes or natural environments and enhancing the image of the overall project. The arch shape itself symbolizes stability and harmony. Combined with the lightweight quality of steel, the result is a bridge form that balances grace with strength. Designers can choose from top-tied, bottom-tied, or tied-arch configurations depending on project needs, and flexibly incorporate design features such as variable arch rib heights, multi-span combinations, or non-standard cross-sections. These elements contribute to the creation of culturally symbolic and visually iconic bridges, making steel arch bridges widely used in cityscapes, scenic areas, and pedestrian bridges.

-

Flexible Thrust Control and Design Adaptability for Complex Foundations

Building on traditional arch principles, steel arch bridges can employ design techniques such as tie rods, hinges, or tension systems to flexibly manage the transfer of arch thrust, significantly reducing dependency on abutments and foundations. In particular, tied-arch bridges convert thrust into tensile force in the tie rod, forming a self-balancing structural system that broadens the range of applicable scenarios. In environments with soft soil, dense underground utilities, or limited abutment construction access, steel arch bridges can be configured to reduce foundation treatment requirements, lower base construction costs, and mitigate construction risks. This structural adaptability allows excellent freedom in layout and strong geological adaptability.

-

Factory Fabrication of Components Ensures Strong Construction Controllability

Key components of steel arch bridges—including arch ribs, crossbeams, and connection nodes—can be modularly prefabricated in factories to ensure precise dimensions and high welding quality, improving the accuracy of the entire structure. On-site construction often utilizes segmented hoisting, temporary support assembly, or arch rib rotation methods, meeting the diverse demands of construction across various terrains. In cases involving high-altitude operations, over-water construction, or projects requiring uninterrupted city traffic, steel arch bridges can leverage advanced fabrication and staged assembly to effectively control the construction schedule and mitigate risks, enhancing both safety and efficiency. This strong controllability is particularly advantageous in large-scale municipal infrastructure projects.

-

Long Service Life and Low Maintenance, Ideal for Long-Term Investment

Thanks to the excellent strength and durability of steel materials, steel arch bridges excel in design life, operational lifespan, and long-term maintenance performance. Proper structural layout and joint design reduce stress concentration points, ensuring long-term structural stability under sustained loads. Additionally, the arch form effectively guides water flow and wind, reducing vibrations and fatigue damage. Internal systems such as anti-corrosion coatings, drainage pathways, and inspection channels can be incorporated to minimize corrosion and maintenance costs. For infrastructure projects aiming for “one-time investment, long-term service,” steel arch bridges offer a compelling combination of structural economy and long-term reliability.

4. Steel Cable-Stayed Bridge

-

Suitable for Medium to Large Spans, with Flexible and Controllable Structural Spans

Cable-stayed bridges efficiently transfer the load from the bridge deck to the tower foundation through the combined action of the main tower and stay cables, making them particularly suitable for medium to large-span bridge projects. They have a wide range of span applications, generally ranging from 100 meters to 1,000 meters, enabling continuous spans and efficient structural arrangements.

Compared to suspension bridges, cable-stayed bridges have higher structural stiffness and do not require large-scale anchorage systems, resulting in a more compact overall structure. In projects with limited space or complex foundation conditions, cable-stayed bridges, due to their self-anchored structural characteristics, can minimize construction interference within the bridge site, making them a common high-performance solution for urban elevated structures, river and sea crossings, and railway bridges.

-

The Main Tower Structure is Tall and Striking, Offering Iconic Urban Landscape Value

The main towers of cable-stayed bridges are typically tall and slender, with a simple and powerful design. Together with multiple sets of stay cables, they form a highly recognizable visual symbol, significantly enhancing the bridge’s visual identity within the urban landscape.

The main tower can adopt various geometric configurations, such as A-type, H-type, Y-type, and inverted Y-type, combined with flexible adjustments to tower height and cable arrangement angles, to meet different aesthetic and engineering design requirements. In many urban core areas or iconic gateway nodes, cable-stayed bridges not only serve as important transportation carriers but are also often endowed with sculptural, commemorative, and other public art functions, making them a core component in shaping the city skyline and landmark imagery.

-

Clear Cable Force Distribution, with Structural Stiffness Superior to Suspension Bridges

The structural system of a cable-stayed bridge consists of a main girder, stay cables, and a main tower. The stay cables directly lift the bridge deck, forming a stable triangular load-bearing system that provides overall stiffness superior to suspension bridges, particularly in terms of resistance to disturbances caused by vehicle loads, wind loads, and seismic forces. The angles and arrangement of the stay cables (such as fan-shaped, parallel, or multi-plane configurations) can be optimized according to mechanical requirements to balance cable force distribution, reduce main girder bending moments, and enhance the performance of the bridge deck. This load-bearing mechanism enables cable-stayed bridges to achieve both long spans and high stiffness without compromising aesthetic appeal.

-

Diverse Construction Methods Adapt to Complex Site Conditions

Cable-stayed bridges can employ various construction methods, including symmetrical cantilever construction, segmental assembly, thrusting, and floating cranes, flexibly adapting to complex conditions such as valleys, water surfaces, and densely populated urban areas. Structural Steel Bridge construction can be carried out by sequentially tensioning and assembling segments symmetrically from the main tower to both sides, offering the advantage of “construction while stabilizing.”

This eliminates the need for large-scale scaffolding, reducing construction interference with the environment and traffic. This characteristic is particularly effective in sites with weak foundation bearing capacity or where traditional scaffolding conditions are unavailable. Additionally, bridge deck and cable system construction can be advanced in parallel, significantly shortening the construction schedule, improving construction organization efficiency, and ensuring project delivery on time.

-

Light Structural Self-Weight, Balancing Maintenance and Economic Efficiency

Since the main beam load is borne by the stay cables, cable-stayed bridges can use lighter steel main beams, reducing material usage and foundation loads. The bridge’s overall load-bearing structure is clear and straightforward, facilitating post-construction operation, management, and maintenance. Monitoring devices can be installed on the cable system, anchorages, and tensioning system to enable real-time health status monitoring, effectively extending service life and mitigating sudden structural risks. By integrating a full lifecycle design philosophy, cable-stayed bridges achieve a harmonious balance between initial investment, operational safety, maintenance convenience, and aesthetic appeal. They have become a benchmark bridge type in current infrastructure projects, combining structural performance with cost control.

5. Structural Steel Bridge Suspension

-

Unmatched Ultra-Long Span Capability, Ideal for Extreme Crossing Projects

Suspension bridges feature a core structure composed of main cables and suspension systems, with the bridge deck suspended by the main cables, significantly reducing the self-weight of the main girder. This makes suspension bridges the structural form with the strongest span capability among all bridge types currently in use. Nearly all bridges worldwide with spans exceeding 1,000 meters are suspension bridges, representing the pinnacle of bridge engineering technology. Suspension structures can easily achieve spans exceeding 2,000 meters, making them ideal for crossing rivers, seas, deep gorges, and wide urban waterways where intermediate piers are impractical. This bridge type is particularly suited for areas with restricted traffic flow, high navigation requirements, or complex geological conditions, offering unparalleled strategic engineering value.

-

The Bridge Deck has a Rational Load-Bearing Design, with a Stable Structure that Combines Flexibility and Rigidity

In suspension bridges, the main cables are subjected to tension, the suspension cables transmit vertical loads, and the main beams bear secondary stresses, ensuring clear functional division among structural components and optimal mechanical performance. The main cables transfer most of the vertical loads to the anchor foundations, significantly reducing internal stresses in the main beams and enabling the bridge deck to exhibit excellent flexible response capabilities. During strong winds, earthquakes, or high-speed train passage, the suspension bridge can absorb kinetic energy through moderate deformation, thereby enhancing seismic and wind stability. Despite its high flexibility, the bridge maintains excellent dynamic stability and traffic safety under long-span conditions through the optimized combination of wind braces, dampers, and steel structure main beams.

-

The Main cables form Elegant Curves, and The Structure is Grand and iconic

The main cables of suspension bridges naturally form parabolic or catenary curves, complemented by vertical suspension cables and towering pylons, creating an overall design that is highly artistic and commemorative. They often become visual focal points of urban skylines or regional gateways. Their grand scale and rhythmically structured form confer a unique cultural identity on the bridges, making them highly visually impactful. From the Golden Gate Bridge in San Francisco to the Yangpu Bridge in Shanghai, suspension bridges are not only important transportation carriers but also iconic structures and symbols of urban spirit. By integrating modern design language with lighting systems, suspension bridges can further enhance the expressiveness of urban landscapes and their nighttime visibility.

-

High Degree of Component Factory Production, Suitable for Modular Crane-Assisted Construction

The main beams of suspension bridges typically adopt steel structure segment forms, facilitating prefabrication in factories to ensure precise dimensions and controllable quality. On-site assembly of segments can be performed using efficient construction methods such as floating cranes, jacking, and cable-supported transportation, making them suitable for sites with large spans, complex water surfaces, or special terrain conditions.

During construction, the installation of the main cables and the hoisting of the main beams can be carried out in parallel, effectively reducing the construction schedule. Additionally, the main cables use a multi-strand steel wire stranded structure, offering high redundancy and tension adjustment capabilities, adapting to complex wind loads and temperature-induced deformations. This ensures both construction and structural safety, making it one of the preferred solutions for large-scale cross-sea engineering projects.

-

Comprehensive Operation and Maintenance Monitoring System with Reasonable Lifecycle Costs

Modern suspension bridges are typically equipped with a complete health monitoring system that continuously collects and analyzes key parameters such as main cable tension, suspension cable deformation, main girder stress, and wind vibration response, enabling 24/7 operational safety management. Main cables can be designed with maintenance access channels, facilitating suspension cable replacement and main girder maintenance. The maintenance management system is well-established. Although initial investment costs are relatively high, the bridge’s lightweight deck, long maintenance intervals, and extended structural lifespan result in favorable comprehensive cost control over its entire lifecycle. Its widespread application in national strategic corridors and major transportation hubs fully validates its economic and sustainable advantages.

Product Parameters

| Material Standard: | AISI, ASTM, BS, DIN, GB, JIS | Steel: | Q235B (commonly used carbon structural steel, suitable for general construction use) | ||

| Q355B (commonly used carbon structural steel, suitable for general construction use) | |||||

| 45# (suitable for components with high strength requirements) | |||||

| 40Cr (alloy structural steel, suitable for parts bearing heavy loads) | |||||

| Country of origin: | China | Certification: | CE (European Union Standard) | ||

| GB (Chinese National Standard) | |||||

| ISO9001 (International Quality Management System Certification) | |||||

| AWS (American Welding Society Certification) | |||||

| Surface treatment: | Primer/Intermediate/Topcoat (color and coating thickness can be customized according to customer needs) | Material Thickness Tolerance: | ±0.5 | ||

| Hot-dip galvanizing (superior corrosion resistance, suitable for harsh environments) | |||||

| Service scope: | Prefabricated Buildings | Wall & Roof Panels: | Steel plate/FRP plate (customized by customers) | ||

| Life: | 50 years | Paint coating: | Provide a variety of colors and coatings according to design requirements. | ||

| Wind resistance: | 12 levels | Shock resistance: | 8 levels | ||

| Quantity (square meters) | 1 – 2000 | 2001 – 5000 | 5001 – 10000 | >10000 | |

| Estimated time (days) | 26 | 35 | 43 | To be negotiated | |

| Service scope: | Design consultation, node deepening, construction plan, installation guidance | ||||

| Pricing method: | One price, no price increase in the middle, transparent price, a nd avoid hidden fees. | ||||

Technical Specifications

To ensure that we can provide a more accurate quotation and preliminary design, we recommend that you provide the following as much information as possible:

- Building appearance: shape, size, and height

- Material standards: Conform to ISO/ASTM/CE/GB standard certification for materials. Steel structure generally uses Q235B and Q355B. Special customization is available upon request.

- Building use: such as industrial plants, warehouses, offices, etc., so that we can reasonably recommend roofing and wall materials

- Load requirements: including live load, snow load, wind load, etc. If there are specific design standards or special usage requirements, please indicate them in advance.

- Coating standards: Through the coating standard certification in ISO/ASTM/CE/GB, we have stringent requirements on the protective performance and environmental adaptability of the coating, the compatibility of the coating, and the adhesion durability.

- Delivery Standard: Complying with the standard certification of products in ISO/AWS D1.1/CE/GB, we always provide customers with high-quality services.

If the above data cannot be provided temporarily, it is not a concern. We will make a preliminary plan for you based on the conventional parameters and further optimize the design in subsequent communication.

Quote Information

Support customized design, welcome to provide drawings for quotation.

Whether you have drawings or not, we welcome cooperation and can provide you with a professional quotation within 1 working day.

- Existing drawings

Please send us your design drawings, and we can provide one-stop service from processing and production, logistics, and delivery to installation guidance. With advanced production technology, complete testing equipment, and a complete technical system, we always provide customers with high-quality and competitive steel structure products.

- No drawings yet

Our design team is experienced and can customize light steel structure buildings according to your needs, including but not limited to gymnasiums, warehouses, workshops, industrial park buildings, halls, and dome building systems.

Professional design team to meet diverse needs

We have a high-level design team that can tailor steel structure solutions according to different project types and customer requirements. To provide more accurate quotations and design solutions, please provide the much information as possible: building purpose, size, load requirements, local standards, etc.

Delivery site photos

|

|

| Delivery of Steel Structure in Sections (Loose Parts) | Delivery of Steel Structure Modular Products (Assembled and Packaged in Units) |

Structural Steel Bridge Practical Application

Urban Expressway Bridges

Urban expressway bridges emphasize compact structure, flexible spanning, and efficient construction, often adopting multi-span continuous bridges or overpasses. Single spans typically range from 30 to 60 meters, with total bridge lengths varying from hundreds of meters to kilometers. Steel structure bridges, with their lightweight and flexible design, effectively minimize impact on urban foundations and underground utilities, making them suitable for construction in space-constrained, high-traffic environments.

Steel box girder bridges or steel truss bridges feature simple structures and smooth visual lines, and can be integrated into urban landscapes through paint design. Factory prefabrication and rapid on-site installation significantly reduce road closure times and minimize disruption to urban traffic operations. The bridge deck has good continuity, enhancing driving smoothness and safety, while also facilitating future expansion or functional adjustments, thereby enhancing the flexibility and scalability of the urban transportation system.

Highway Bridges

Highway bridges typically span valleys, plains, or existing major transportation routes, with bridge lengths ranging from several hundred meters to over a kilometer. They have high design requirements for standard lane traffic and a large safety factor. Steel structure bridges can accommodate medium to large spans, particularly advantageous in cases of complex bridge abutment foundation conditions or constrained construction schedules.

Steel box girder bridges offer excellent torsional resistance and overall stiffness, suitable for configurations of six lanes or more; steel structure truss bridges can be flexibly segmented and constructed modularly, effectively improving construction efficiency and quality consistency. The bridge deck exhibits superior seismic performance, adapting to high-speed load changes and enhancing driving stability. The bridge has a neat appearance, is easy to maintain and monitor, and, combined with a durable corrosion protection system, can achieve a service life of over 50 years, ensuring the reliability and economic efficiency of long-term operation on high-speed trunk lines.

Railway Structural Steel Bridges

Railway bridges emphasize high-strength load-bearing capacity and structural stability, with design speeds typically ranging from 160 to 350 kilometers per hour, high axle loads, frequent vibrations, and single spans generally between 32 and 72 meters. Steel structure bridges are widely used in high-speed and heavy-load railway projects due to their superior strength-to-weight ratio and controllable vibration performance. Steel structure truss bridges have high structural rigidity and minimal deformation, meeting the stringent requirements for track precision when trains pass at high speeds; steel structure box girder bridges can achieve a continuous and smooth bridge deck, reducing noise and maintenance burdens.

The structural technology is mature, facilitating rapid construction in complex environments such as high piers and deep valleys. The bridges offer high operational safety, with the option to install track vibration damping devices and intelligent monitoring systems, effectively enhancing train running stability and overall operational efficiency, making them a key component of modern railway infrastructure.

Cross-River and Cross-Sea Channels

Cross-river and cross-sea bridges require ultra-large spans, high wind resistance, and long-term durability, with spans typically exceeding 1,000 meters. They must consider navigable clearance and varying environmental conditions. Steel structure bridges primarily use suspension bridges or cable-stayed bridges, which offer exceptional crossing capabilities and construction adaptability, particularly suited for extreme conditions such as deep water, strong currents, and weak geological conditions.

The main cables and towers are flexibly arranged, creating a grand bridge design that combines transportation functionality with visual landmark significance. Steel structure main beams can be precisely prefabricated and modularly installed, significantly reducing offshore construction time and safety risks. Corrosion-resistant treatment of the bridge deck and intelligent maintenance systems ensures long-term stable operation in complex marine environments, making them critical carriers for national strategic transportation hubs and regional economic connectivity.