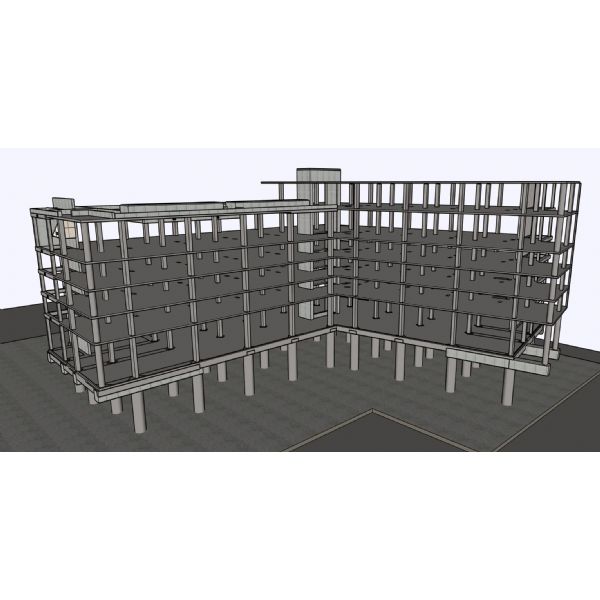

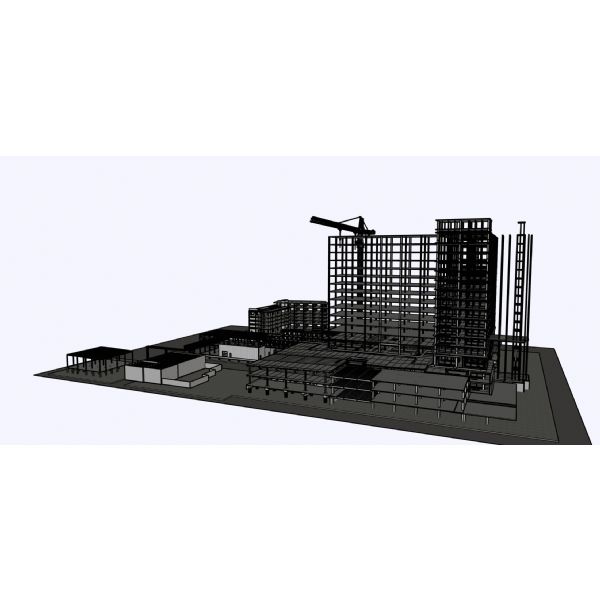

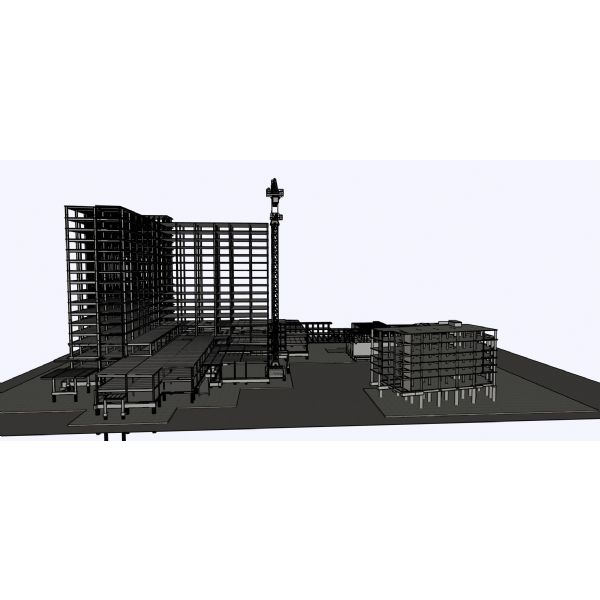

Steel Structure Concrete High-rise 3D Render

Product Advantages

This structural form demonstrates excellent mechanical performance, particularly in resisting lateral forces. It effectively addresses common high-rise load conditions such as wind loads and seismic effects. Steel components provide high strength and ductility, while the reinforced concrete core enhances overall stiffness and torsional resistance. Together, they complement each other, ensuring a balance between structural safety and spatial flexibility. Moreover, its flexible structural layout adapts to various functional requirements of high-rise spaces, including office buildings, apartments, hotels, and large-scale commercial complexes.

Steel structure concrete high-rise offers prominent advantages, including low self-weight, fast construction, high degree of standardization, and efficient material utilization. Steel components can be prefabricated in factories, while concrete work proceeds simultaneously on-site, achieving efficient coordination between structural construction and MEP (mechanical, electrical, and plumbing) installations, greatly shortening the construction schedule. Moreover, this structural system facilitates phased development and zoned operation, aligning with modern high-rise demands for multifunctionality, energy efficiency, and sustainability.

At present, steel structure concrete high-rise buildings are widely used in urban cores, financial business districts, high-end residential clusters, and super high-rise landmark projects. They are particularly suitable for developments with stringent requirements for building height, structural performance, and construction efficiency, making them an ideal structural solution for high-density urban development and landmark architecture.

- Superior Structural Performance with Strong Seismic and Wind Resistance: The Steel Structure Concrete High-rise system forms an excellent lateral force-resisting structure through the synergy between the high strength of steel components and the high stiffness of the concrete core. Steel offers good ductility, effectively absorbing seismic energy and significantly enhancing earthquake resistance. At the same time, the system provides large overall stiffness, demonstrating outstanding performance in resisting wind loads commonly encountered in high-rise buildings. Compared with traditional concrete structures, it offers stronger stability and deformation control, making it ideal for high-rise and super high-rise buildings by ensuring structural safety and occupant comfort under complex load conditions.

- Small component cross-sections and high space utilization: Due to the high strength and load-bearing capacity of steel structures, structural components require smaller cross-sectional dimensions, resulting in compact columns and beams, effectively freeing up more usable space. This is particularly true in high-rise buildings such as offices, apartments, and hotels, which place high demands on interior space layout and natural light. Steel-concrete systems can significantly increase building utilization, bringing greater economic benefits to building operations and flexibility for future development.

- High Degree of Prefabrication, Short Construction Period: This structural system extensively uses standardized steel components, which can be prefabricated in factories through cutting, welding, and assembly, ensuring high processing precision and construction quality. On-site work mainly involves hoisting and joint connection, coordinated with simultaneous casting of floor slabs or the concrete core, greatly reducing on-site construction time. In addition, construction is less affected by weather conditions, making it especially suitable for projects with tight schedules or those located in dense urban areas with restricted site conditions.

- Flexible Functional Layout with Strong Adaptability: The structural layout of Steel Structure Concrete High-rises is highly flexible. The column grid can be adjusted according to various functional needs, supporting different building types such as offices, residences, hotels, commercial centers, and transportation hubs. Large open spaces and flexible partitioning can be easily achieved, facilitating future interior renovations, MEP installations, and functional upgrades—thereby improving adaptability and long-term value throughout the building’s lifecycle.

- Energy Efficient and Environmentally Friendly Construction: Steel is a recyclable material, and on-site construction with this system causes minimal disruption and pollution, aligning with green construction principles. By incorporating technologies such as integrated insulation wall panels, hollow floor slabs, and shading components, the building can achieve excellent energy-saving performance. Furthermore, the short construction cycle, reduced material waste, and efficient transportation help lower carbon emissions and minimize the environmental impact throughout the entire building process, meeting the demands of modern urban green development.

- Reasonable Overall Cost Control and High Investment Return: Although steel materials have a relatively higher unit cost, the rapid construction speed, high space utilization, and ease of post-maintenance effectively reduce overall development and operational costs. Early completion and usage of the project also translates to faster investment returns. Especially for high-rise and super high-rise projects, the use of the Steel Structure Concrete High-rise system strikes an ideal balance between safety, cost-effectiveness, and construction efficiency—making it a preferred structural solution for capital-intensive developments.

Product Parameters

| Material Standard: | AISI, ASTM, BS, DIN, GB, JIS | Steel: | Q235B (commonly used carbon structural steel, suitable for general construction use) | ||

| Q355B (commonly used carbon structural steel, suitable for general construction use) | |||||

| 45# (suitable for components with high strength requirements) | |||||

| 40Cr (alloy structural steel, suitable for parts bearing heavy loads) | |||||

| Country of origin: | China | Certification: | CE (European Union Standard) | ||

| GB (Chinese National Standard) | |||||

| ISO9001 (International Quality Management System Certification) | |||||

| AWS (American Welding Society Certification) | |||||

| Surface treatment: | Primer/Intermediate/Topcoat (color and coating thickness can be customized according to customer needs) | Material Thickness Tolerance: | ±0.5 | ||

| Hot-dip galvanizing (superior corrosion resistance, suitable for harsh environments) | |||||

| Service scope: | Prefabricated Buildings | Wall & Roof Panels: | Steel plate/FRP plate (customized by customers) | ||

| Life: | 50 years | Paint coating: | Provide a variety of colors and coatings according to design requirements. | ||

| Wind resistance: | 12 levels | Shock resistance: | 8 levels | ||

| Quantity (square meters) | 1 – 2000 | 2001 – 5000 | 5001 – 10000 | >10000 | |

| Estimated time (days) | 26 | 35 | 43 | To be negotiated | |

| Service scope: | Design consultation, node deepening, construction plan, installation guidance | ||||

| Pricing method: | One price, no price increase in the middle, transparent price, a nd avoid hidden fees. | ||||

Technical Specifications

To ensure that we can provide a more accurate quotation and preliminary design, we recommend that you provide the following as much information as possible:

- Building appearance: shape, size, and height

- Material standards: Conform to ISO/ASTM/CE/GB standard certification for materials. Steel generally uses Q235B and Q355B. Special customization is available upon request.

- Building use: such as industrial plants, warehouses, office buildings, etc., so that we can reasonably recommend roofing and wall materials

- Load requirements: including live load, snow load, wind load, etc. If there are specific design standards or special usage requirements, please indicate them in advance.

- Coating standards: Through the coating standard certification in ISO/ASTM/CE/GB, we have stringent requirements on the protective performance and environmental adaptability of the coating, its compatibility, and its adhesion durability.

- Delivery Standard: Complying with the standard certification of products in ISO/AWS D1.1/CE/GB, we always provide customers with high-quality services.

It is not a concern if the above data cannot be provided temporarily. We will make a preliminary plan for you based on the conventional parameters and further optimize the design in subsequent communication.

Quote Information

Support customized design, welcome to provide drawings for quotation.

Whether you have drawings or not, we welcome cooperation and can provide you with a professional quotation within 1 working day.

Existing drawings

Please send us your design drawings, and we can provide one-stop service from processing and production, logistics, and delivery to installation guidance. With advanced production technology, complete testing equipment, and a complete technical system, we always provide customers with high-quality and competitive steel structure products.

No drawings yet

Our design team is experienced and can customize light steel structure buildings according to your needs, including but not limited to gymnasiums, warehouses, workshops, industrial park buildings, halls, and dome building systems.

Professional design team to meet diverse needs

We have a high-level design team that can tailor steel structure solutions according to different project types and customer requirements. To provide more accurate quotations and design solutions, please provide the much information as possible: building purpose, size, load requirements, local standards, etc.

Delivery site photos

|

|

| Delivery of Steel Structure Components (Container Packing) | Delivery of Steel Structure in Sections (Loose Parts) |

|

|

| Delivery of Steel Structure Combinations (Mixed Method) | Delivery of Steel Structure Modular Products (Assembled and Packaged in Units) |

Practical Application

Commercial Complexes

The application of Steel Structure Concrete High-rises in commercial complexes has become a prevailing trend. This structural system typically features floor heights ranging from 4.2 to 5.5 meters to meet commercial operational requirements for space height and clearances. The total building height usually falls between 80 and 150 meters, accommodating integrated layouts for multifunctional commercial formats.

The steel structure component provides flexibility for large-span, column-free spaces, enhancing internal circulation transparency and tenant layout versatility. Combined with a reinforced concrete core, the overall system improves structural stability and lateral resistance, meeting seismic and fire safety demands in high-density urban centers. Under standardized design and prefabricated construction methods, the construction period for such projects is generally controlled within 8 to 12 months, significantly shortening the development timeline and reducing on-site labor intensity.

High-Rise Apartments

In high-rise residential and apartment buildings, Steel Structure Concrete High-rises can achieve standard floor heights of 3.0 to 3.3 meters, satisfying residential comfort while ensuring energy efficiency. The total building height is typically controlled between 80 and 120 meters, accommodating 25 to 35 floors of residential units.

This structural system leverages the combined performance of steel beams, steel columns, and the concrete core to achieve an optimal balance between lightweight strength and stiffness control, resulting in more uniform load distribution and reduced deformation. Construction integrates prefabricated components with on-site welding or bolted connections, enhancing both construction efficiency and safety. The main structure of an entire residential tower is typically completed within 6 to 9 months, making it especially suitable for urban renewal and large-scale residential development.

Office Steel Structure Buildings

Steel Structure Concrete High-rises are widely used in office building construction, with typical floor heights ranging from 3.9 to 4.5 meters to accommodate office net height and MEP service layers. Total building heights often range from 100 to 160 meters, suitable for mid- to high-rise office projects over 30 stories. The composite structural system achieves a balance between stiffness, load capacity, and cost-effectiveness in high-rise buildings.

It is especially well-suited for a core-tube + frame-brace configuration, effectively resisting wind loads and seismic forces. The use of standardized components facilitates streamlined and assembly-based construction, improving building efficiency. The structural construction period for such office towers is typically controlled within 9 to 13 months, aligning well with the needs of modern enterprises for rapid commissioning and early operation.

Hotels

Hotel buildings impose far greater demands on design and construction than many other types of high-rise projects. Unlike standard residential or office towers, hotel projects must simultaneously achieve structural stability, occupant comfort, and precise construction schedules to meet investor and operator expectations. Guests require not only safety but also an environment that offers comfort, privacy, and efficiency, making the structural system a cornerstone of success.

The Steel Structure Concrete High-rise system has emerged as a highly effective solution to meet these demands. This system typically incorporates floor heights between 3.6 and 4.2 meters, which are ideal for accommodating luxury hotel standards such as spacious lobbies, banquet halls, and guestrooms with generous ceiling heights. With total building heights generally ranging from 90 to 130 meters, this system is perfectly suited for 25- to 30-story high-star hotel projects. Such dimensions allow developers to achieve both architectural elegance and the operational capacity needed for large-scale hospitality operations.

One of the greatest strengths of this structural system lies in its hybrid approach. It combines the lightweight and rapid construction benefits of steel with the stiffness and stability provided by a reinforced concrete core. The steel framework enables quicker assembly, reduced foundation loads, and enhanced resistance to seismic activity, while the concrete core ensures robustness in vertical circulation areas such as elevator shafts, stairwells, and mechanical risers. Together, these elements guarantee not only stability but also the flexibility to adapt room layouts according to hotel design requirements.

Flexibility is particularly vital in high-end hotels where functionality and aesthetics must align. The structural system allows architects to optimize layouts for guestrooms, suites, and service areas without being constrained by excessive columns or supports. Furthermore, the integration of steel and concrete provides excellent sound insulation and thermal performance, ensuring guests experience quiet, comfortable rooms with minimal energy consumption. This contributes to both operational efficiency and sustainability goals that modern hotel operators prioritize.

In addition to performance benefits, the construction timeline is a major advantage of the Steel Structure Concrete High-rise system. By using prefabricated steel components, hoisting technologies, and standardized formwork systems, the primary structure of a hotel can typically be completed within 7 to 10 months. This accelerated schedule allows developers to allocate ample time for interior decoration and finishing, which are crucial aspects of luxury hotel delivery. Since interiors often define the guest experience, ensuring sufficient time for these works greatly improves final quality while also guaranteeing timely project handover.

The efficiency of this system does not compromise long-term durability. Hotels built with this method demonstrate exceptional resilience against natural forces such as wind and earthquakes, while also maintaining low maintenance requirements. Combined with the aesthetic freedom offered by steel’s versatility, this approach allows developers to construct landmark hotel buildings that balance speed, safety, comfort, and elegance.

Ultimately, the Steel Structure Concrete High-rise system represents the future of modern hotel construction. It enables developers and operators to meet stringent requirements for structural performance, guest comfort, sustainability, and project timelines, making it the preferred choice for world-class hospitality projects.