Steel Structure Infrastructure 3D Render

Product Advantages

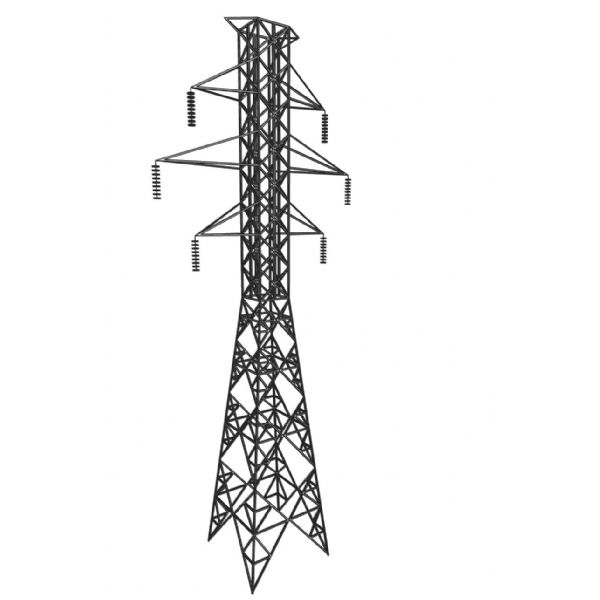

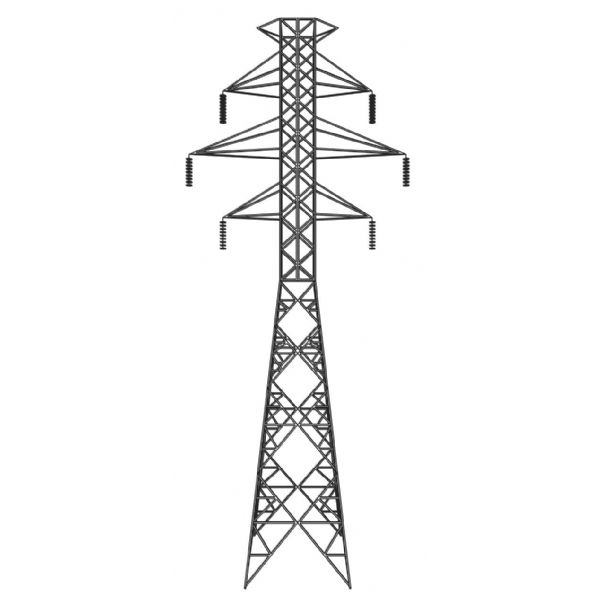

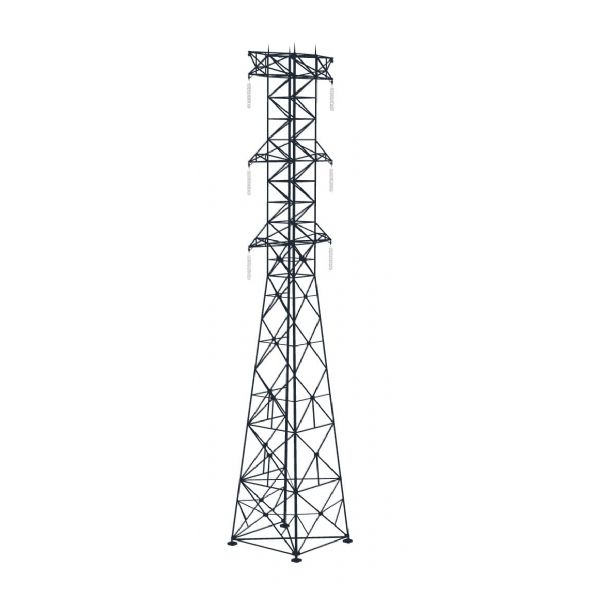

Transmission Tower

A steel structure transmission tower is a tall structure assembled and welded from section steel or angle steel, commonly used for power transmission, high-voltage line support, and long-distance overhead line deployment. Its overall structure is primarily composed of steel, combined through bolted or welded connections into truss-type, lattice-type, or monopole configurations, adaptable to various terrain conditions and load requirements.

This structure features excellent wind resistance and spatial rigidity, capable of maintaining stability over long periods under high-intensity working environments. Thanks to the lightweight and high-strength characteristics of steel, the tower has relatively low self-weight, facilitating transportation and hoisting, while also offering good durability and ease of maintenance—making it suitable for large-scale inter-regional deployment.

Steel structure transmission towers offer notable advantages such as modular construction, quick installation, and adaptability to complex topographies. Their standardized design not only enhances manufacturing and construction efficiency but also reduces construction difficulty and labor costs, playing an irreplaceable role in large-scale power facilities and communication engineering.

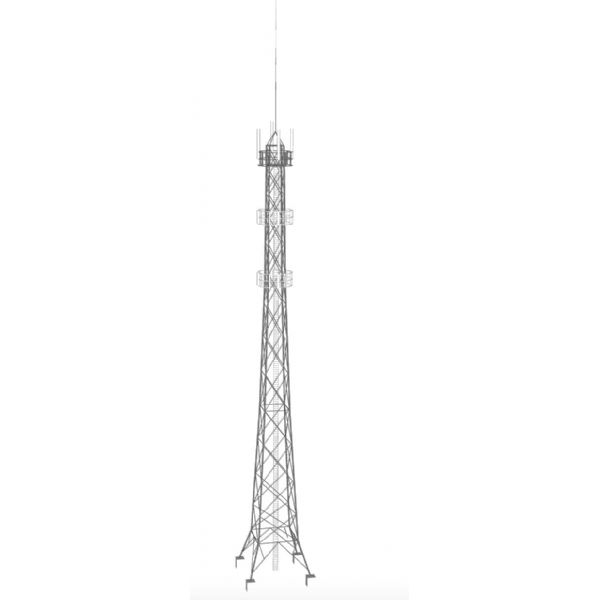

Lightning Protection Tower

A steel structure lightning protection tower is a tall structure specially designed for lightning protection of buildings, warehouses, and equipment areas. Its main structure is welded from steel pipes or angle steel, with a lightning rod system installed at the top to ensure effective conduction of lightning energy into the ground, thereby safeguarding surrounding equipment and personnel.

The structural design of the lightning tower emphasizes high strength and electrical conductivity, achieving efficient protection without occupying a large footprint. By optimizing node connection methods and member cross-section configurations, the entire tower has excellent seismic and wind resistance, suitable for long-term operation under various climatic and environmental conditions.

Steel structure lightning towers offer multiple advantages, such as flexible installation, short construction periods, and low maintenance costs. They can be flexibly customized according to project height requirements and are widely used in warehousing zones, industrial and mining enterprises, petrochemical facilities, airports, and around high-rise buildings as part of comprehensive lightning protection systems to ensure structural and personnel safety.

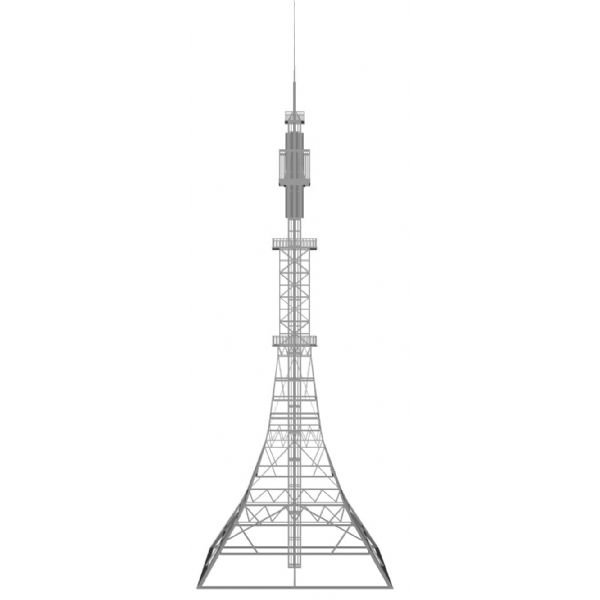

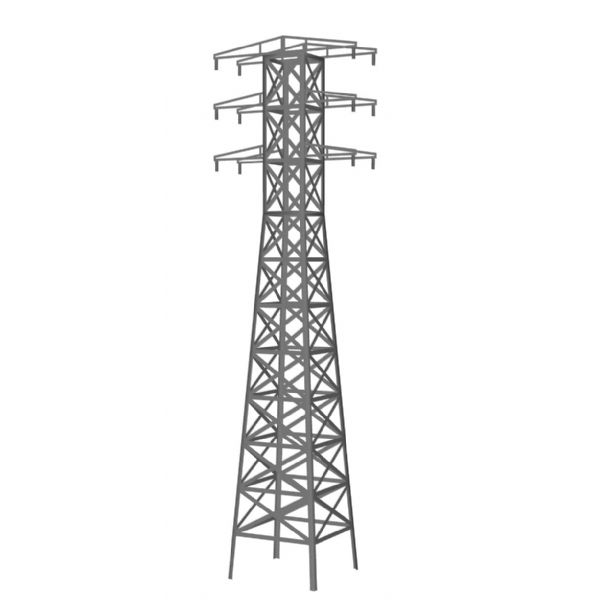

Signal Tower

A steel structure signal tower is a tall support structure specifically designed for transmitting mobile communication, broadcast television, microwave, and satellite signals. Common structural forms include triangular truss towers. Functionally, they can accommodate base station antennas, cameras, navigation, and monitoring equipment in various configurations.

Signal towers focus on load-bearing capacity and stability, with tower body designs prioritizing lightweight construction while ensuring excellent overall rigidity and wind resistance. Steel structural materials ensure high durability and corrosion resistance, meeting the demands of continuous operation in harsh environments such as coastal areas, mountains, and wilderness.

These towers are characterized by high installation efficiency, ease of maintenance, and a high degree of structural standardization, making them especially suitable for the rapid deployment of communication networks and emergency response systems. Steel structure signal towers are widely used in telecom base stations, transportation hubs, highways, and core communication scenarios such as surveillance and early warning systems.

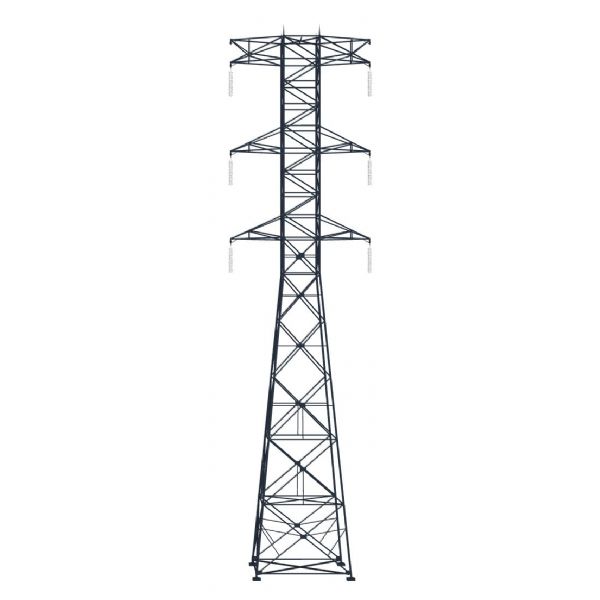

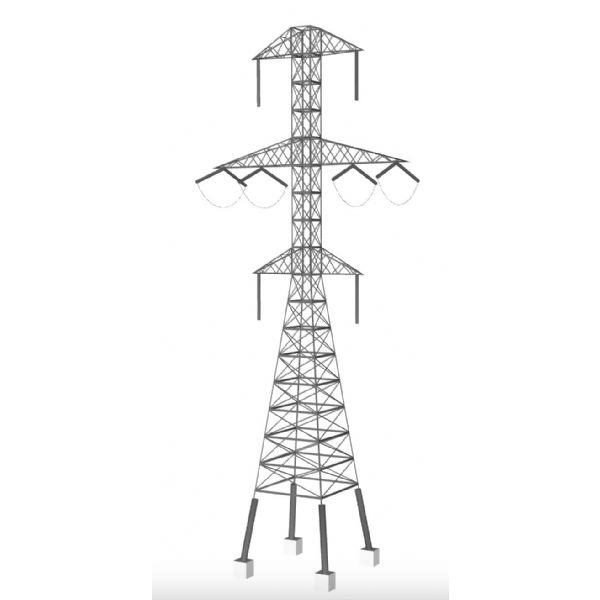

Power Transmission System

Steel structures in power transmission systems mainly include substation steel frames, cable supports, power utility corridors, and overhead line support structures, designed to provide stable and secure support for high-voltage power transmission, power transformation, and distribution equipment and circuits. These structures are typically composed of hot-rolled H-shaped steel, angle steel, and round pipe combinations.

Such structures must possess excellent load-bearing capacity, seismic performance, and corrosion resistance to ensure the continuous and reliable operation of power transmission systems in complex environments. Through bolted connections and optimized node layouts, they allow for rapid assembly and future expansion, meeting the construction needs of large-scale power networks.

Steel structure power transmission systems offer distinct advantages such as high integration, high reliability, and low life-cycle costs, making them particularly suitable for scenarios including new energy power stations, urban substations, and long-distance transmission corridors. While ensuring the efficient operation of the system, they also support the development of smart grids and green energy infrastructure.

Steel Structure Infrastructure Advantages

Excellent Structural Performance to Meet Extreme Conditions

One of the most significant advantages of steel structures in Steel Structure Infrastructure is their outstanding structural performance. For vertical structures such as transmission towers, lightning protection towers, and signal towers, which often face harsh climate conditions including strong winds, high temperatures, lightning strikes, and snow loads, steel structures exhibit exceptional tensile strength and compressive stiffness, offering high stability and deformation resistance. Especially in high-altitude or high-wind regions, traditional concrete or wooden structures often fall short, whereas steel structures become the preferred option due to their high strength, low weight, and superior mechanical properties.

Steel components can be optimized in cross-sectional design to form lightweight, high-strength member systems that meet the stability requirements of towers while significantly reducing the self-weight load on the foundation, improving overall economic efficiency and safety margin. For power transmission towers within electric systems, steel structures can also flexibly accommodate different line directions by combining standardized angle steel, hot-rolled H-section steel, and node components to form diverse tower configurations, enabling efficient and precise engineering design. The superior structural performance not only ensures reliable operation under extreme natural conditions but also provides greater flexibility for future maintenance and upgrades.

High Construction Efficiency and Cost Reduction Through Standardized Manufacturing

A key feature of Steel Structure Infrastructure is its large-scale deployment and frequent replication. Compared with traditional structural systems, steel structures boast high levels of prefabrication and on-site assembly efficiency, significantly enhancing construction speed. For instance, communication signal towers and power transmission towers usually adopt standardized components such as angle steel and section steel, with all members and joints pre-cut, drilled, welded, and hot-dip galvanized in factories, forming modular units that can be rapidly assembled on site.

This construction method not only shortens construction periods but also greatly reduces dependence on manual labor, making it especially suitable for remote areas such as mountainous regions, plateaus, and forests. Additionally, steel structure facilities are not subject to seasonal construction limitations, making them ideal for emergency response projects or mass deployments.

Take lightning protection towers as an example—typically installed as standalone structures on rooftops or open fields, they use factory-produced steel pipe columns and lightning rod components, enabling immediate installation upon hoisting, significantly reducing rooftop work time and high-altitude construction risks. Short construction cycles, a high degree of standardization, and strong controllability are fundamental guarantees for the rapid advancement of steel structure infrastructure in modern foundational construction.

Strong Adaptability and Scalability for Multi-scenario Applications

Steel structures in Steel Structure Infrastructure demonstrate strong adaptability and scalability, particularly suitable for deployment across diverse environments and scattered regions. For example, signal towers face vastly different base station layout requirements between urban and rural areas—some demand high concealment with architectural integration, while others require towering structures with large spans. Steel components allow for flexible adjustments in height, tower shape, and foundation connections, and can be custom-designed based on geological and topographical conditions to ensure both structural safety and spatial harmony.

In power transmission systems, transmission towers must span rivers, mountains, farmland, and residential areas. Steel structures, with lightweight design and modular node connection technologies, can accommodate site-specific tower types, including straight-line towers, angle towers, and terminal towers, to suit complex route layouts. Meanwhile, steel tower bodies also offer excellent functional integration capabilities, allowing the incorporation of monitoring, lighting, surveillance, and broadcasting equipment, enabling “multi-purpose towers” or future upgrade provisions.

The adaptability of steel structures is reflected not only in their diverse structural forms but also in their compatibility with varying use demands, technology updates, and maintenance needs—positioning them as vital carriers in future intelligent infrastructure systems.

Easy Maintenance and Lower Lifecycle Cost

Steel structure infrastructure demonstrates strong durability and maintainability over long-term use, which is key to ensuring lifecycle economic efficiency. Modern steel materials commonly use advanced protective treatments such as hot-dip galvanizing, anti-corrosion coatings, and fluorocarbon finishes, greatly enhancing resistance to corrosion in outdoor environments and preventing structural degradation from rain, humidity, and salt mist—thus extending service life.

For instance, transmission and lightning protection towers are constantly exposed to harsh atmospheric conditions and climate changes. While traditional structures are prone to cracking or weathering, steel structures maintain surface integrity through protective coatings, significantly reducing the need for subsequent maintenance.

Additionally, steel components can be modularly replaced; in the event of damage, only the affected parts need to be swapped, eliminating the need for full demolition or major repairs—reducing both maintenance costs and operational disruptions.

For electric transmission facilities, periodic inspections, component reinforcement, and re-coating work are also more efficient thanks to the accessibility and openness of steel structures. From a lifecycle perspective, although steel structures may require higher initial investment, their lower maintenance frequency, ease of replacement, and long service life lead to significantly lower total costs than traditional systems—making them a cornerstone of long-term infrastructure management.

Product Parameters

| Material Standard: | AISI, ASTM, BS, DIN, GB, JIS | Steel: | Q235B (commonly used carbon structural steel, suitable for general construction use) | ||

| Q355B (commonly used carbon structural steel, suitable for general construction use) | |||||

| 45# (suitable for components with high strength requirements) | |||||

| 40Cr (alloy structural steel, suitable for parts bearing heavy loads) | |||||

| Country of origin: | China | Certification: | CE (European Union Standard) | ||

| GB (Chinese National Standard) | |||||

| ISO9001 (International Quality Management System Certification) | |||||

| AWS (American Welding Society Certification) | |||||

| Surface treatment: | Primer/Intermediate/Topcoat (color and coating thickness can be customized according to customer needs) | Material Thickness Tolerance: | ±0.5 | ||

| Hot-dip galvanizing (superior corrosion resistance, suitable for harsh environments) | |||||

| Service scope: | Prefabricated Buildings | Wall & Roof Panels: | Steel plate/FRP plate (customized by customers) | ||

| Life: | 50 years | Paint coating: | Provide a variety of colors and coatings according to design requirements. | ||

| Wind resistance: | 12 levels | Shock resistance: | 8 levels | ||

| Quantity (square meters) | 1 – 2000 | 2001 – 5000 | 5001 – 10000 | >10000 | |

| Estimated time (days) | 26 | 35 | 43 | To be negotiated | |

| Service scope: | Design consultation, node deepening, construction plan, installation guidance | ||||

| Pricing method: | One price, no price increase in the middle, transparent price, a nd avoid hidden fees. | ||||

Technical Specifications

To ensure that we can provide a more accurate quotation and preliminary design, we recommend that you provide the following as much information as possible:

- Building appearance: shape, size, and height

- Material standards: Conform to ISO/ASTM/CE/GB standard certification for materials. Steel generally uses Q235B and Q355B. Special customization is available upon request.

- Building use: such as industrial plants, warehouses, offices, etc., so that we can reasonably recommend roofing and wall materials

- Load requirements: including live load, snow load, wind load, etc. If there are specific design standards or special usage requirements, please indicate them in advance.

- Coating standards: Through the coating standard certification in ISO/ASTM/CE/GB, we have stringent requirements on the protective performance and environmental adaptability of the coating, the compatibility of the coating, and the adhesion durability.

- Delivery Standard: Complying with the standard certification of products in ISO/AWS D1.1/CE/GB, we always provide customers with high-quality services.

If the above data cannot be provided temporarily, it is not a concern. We will make a preliminary plan for you based on the conventional parameters and further optimize the design in subsequent communication.

Quote Information

Support customized design, welcome to provide drawings for quotation.

Whether you have drawings or not, we welcome cooperation and can provide you with a professional quotation within 1 working day.

- Existing drawings

Please send us your design drawings, and we can provide one-stop service from processing and production, logistics, and delivery to installation guidance. With advanced production technology, complete testing equipment, and a complete technical system, we always provide customers with high-quality and competitive steel structure products.

- No drawings yet

Our design team is experienced and can customize light steel structure buildings according to your needs, including but not limited to gymnasiums, warehouses, workshops, industrial park buildings, halls, and dome building systems.

Professional design team to meet diverse needs

We have a high-level design team that can tailor steel structure solutions according to different project types and customer requirements. To provide more accurate quotations and design solutions, please provide the much information as possible: building purpose, size, load requirements, local standards, etc.

Delivery site photos

|

|

| Delivery of Steel Structure Components (Container Packing) | Delivery of Steel Structure in Sections (Loose Parts) |

|

|

| Delivery of Steel Structure Combinations (Mixed Method) | Delivery of Steel Structure Modular Products (Assembled and Packaged in Units) |

Practical Application

Transmission Towers: Critical Structural Support for Communications and Power Delivery

Steel transmission towers, as tall spatial truss components, are widely used in communication base stations, broadcasting, meteorological observation, and high-voltage power transmission systems. In both urban and rural areas, they not only support antennas, optical cables, navigation equipment, and similar devices but also serve as essential infrastructure for long-distance signal and power transmission. With excellent wind and seismic resistance, they can operate stably in various challenging environments—whether in coastal regions, mountainous terrains, or densely populated urban zones.

Transmission towers come in various structural forms, including angle steel towers, tubular steel towers, and mast towers, which can be flexibly adapted to specific scenarios and load requirements. Modular construction significantly improves efficiency, allowing for factory prefabrication and rapid on-site assembly. With long maintenance intervals and extended service life, these towers reduce long-term operating costs. Steel transmission towers remain an irreplaceable component in modern infrastructure development.

Lightning Protection Towers: Structural Shielding Systems for Critical Facility Safety

Steel lightning protection towers are extensively used in substations, power plants, chemical parks, fuel storage zones, data centers, and high-rise buildings to provide effective lightning protection for both equipment and personnel. Typically constructed as self-supporting steel pipe or angle steel towers, they safely direct lightning current to the ground via tall conductive structures, preventing surges from entering buildings or electrical systems.

Tower height is meticulously calculated based on protection radius, lightning density, and surrounding environmental conditions to ensure the formation of a reliable protective cone. Steel’s inherent conductivity, durability, wind resistance, and corrosion resistance make it ideal for extreme weather conditions. Prefabrication and bolted connections are used to enhance high-altitude work safety and installation efficiency. As a foundational element of industrial safety and urban operations, lightning protection towers provide the first line of defense for sensitive infrastructure.

Signal Towers: Elevated Platforms for Critical Communication Hubs

Signal towers are essential components of modern communication systems, widely deployed on urban rooftops, major transport corridors, suburban areas, and alongside highways. They support various antenna systems for mobile communications, broadcasting, GPS, and more. Steel signal towers offer high strength, a lightweight structure, and ease of installation. Typical structural types include triangular trusses, with design customized to match frequency bands, antenna loads, and local wind conditions.

Tower height is adjustable to suit coverage radius needs, and the design supports multi-platform antenna deployment to enhance spectral resource utilization. Thanks to their clear structural systems, signal towers allow for efficient prefabrication, short construction cycles, and easy maintenance—enabling rapid deployment of new base stations or capacity expansion of existing networks. In the construction of next-generation infrastructure such as 5G and satellite internet, steel signal towers will continue to play a central role in ensuring broad, high-speed network coverage as key physical carriers.

Power Transmission Systems: Structural Carriers Supporting High-Voltage Grid Operations

Steel structures in power transmission systems include transmission towers, substation frames, cable trays, and wire brackets, and are widely used in urban and rural power grids. These components support high-voltage transmission lines and ensure electricity is delivered efficiently, stably, and safely from power plants to end users.

Depending on voltage level and span requirements, steel transmission towers can be designed as suspension towers, angle towers, tension towers, or terminal towers, with structural forms such as angle steel towers and tubular towers. Design considerations include conductor tension, wind loads, and ice accumulation, ensuring excellent wind and seismic resistance and long-term durability.

With modular design and standardized manufacturing, steel components for power transmission can be produced efficiently and installed quickly, significantly reducing construction time and labor costs. As the development of “new-type power systems” and smart grids accelerates, steel structure power transmission systems are continuously evolving to meet high-capacity, long-span, and green low-carbon transmission demands.