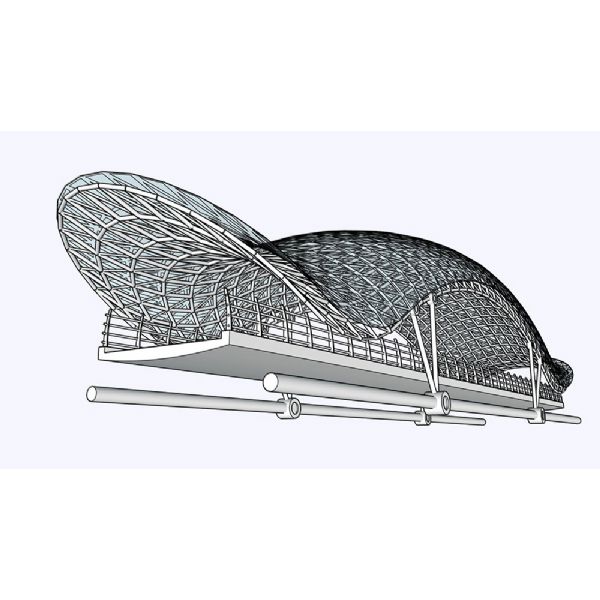

Steel Structure Corridor 3D Render

Product Advantages

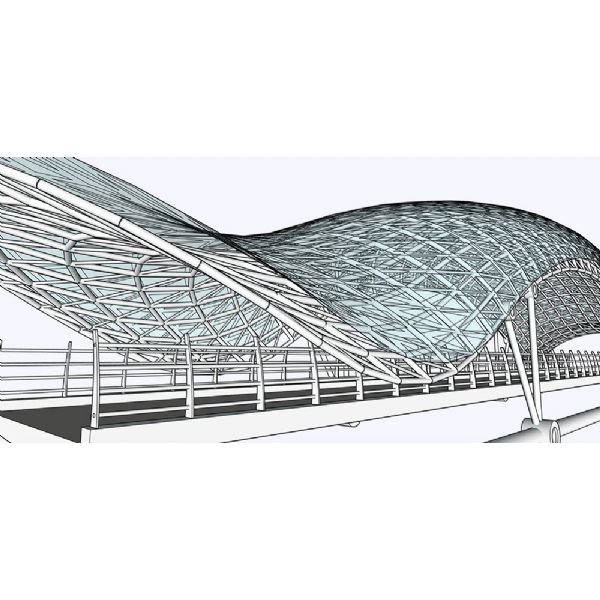

This structure typically adopts multi-dimensional layouts and three-dimensional node connections, forming a spatial steel structural system with clear load paths and overall stability. It features good structural stiffness and mechanical performance, enabling column-free spans, long-span connections, multi-angle turns, and complex geometric configurations, effectively accommodating various site conditions and architectural layouts. With high design flexibility, it can be customized according to specific project requirements, balancing functionality and aesthetics to provide precise structural solutions for different applications.

In terms of performance, the Steel Structure Corridor has a lightweight structure, rational force distribution, and high material utilization, which not only enhances structural stability but also helps reduce construction costs. Its outstanding seismic performance allows it to adapt to complex and variable geological environments, ensuring reliable safety. Moreover, the Steel Structure Corridor features a strong capacity for factory prefabrication and rapid on-site assembly, enabling standardized and modular construction processes that effectively shorten construction periods and improve installation efficiency and quality.

Currently, Steel Structure Corridors are widely applied in large commercial complexes, urban integrated campuses, medical institutions, university campuses, transportation hubs, and airport terminals. They are especially suited for projects that demand a high degree of structural aesthetics and spatial expression. As a key element in modern urban planning and development, the Steel Structure Corridor not only connects buildings—it also connects space, functionality, and aesthetics. To achieve high-quality construction, it is essential to fully understand its structural characteristics and develop scientifically sound design and construction plans to ensure smooth project execution and excellent final quality.

- Lightweight Structure with Long Spans: The Steel Structure Corridor, constructed primarily with high-strength steel, offers exceptional load-bearing capacity while maintaining a lightweight profile, effectively reducing the burden on the foundation. This structural form is especially suitable for medium to long-distance connections between buildings, easily achieving column-free spans of over 10 meters—and even longer—meeting modern architectural demands for open space and efficient pedestrian circulation. Compared with traditional concrete structures, the Steel Structure Corridor more easily adapts to terrain elevation differences, ground-level obstacles, or specific layout requirements, minimizing ground-level space usage and disruption. While ensuring structural safety, its lightness and flexible form greatly enhance the freedom of overall architectural design. Additionally, steel’s excellent toughness and ductility allow it to maintain stability and resistance to deformation under wind loads or temperature stresses, making it an ideal solution for lightweight, long-span structures.

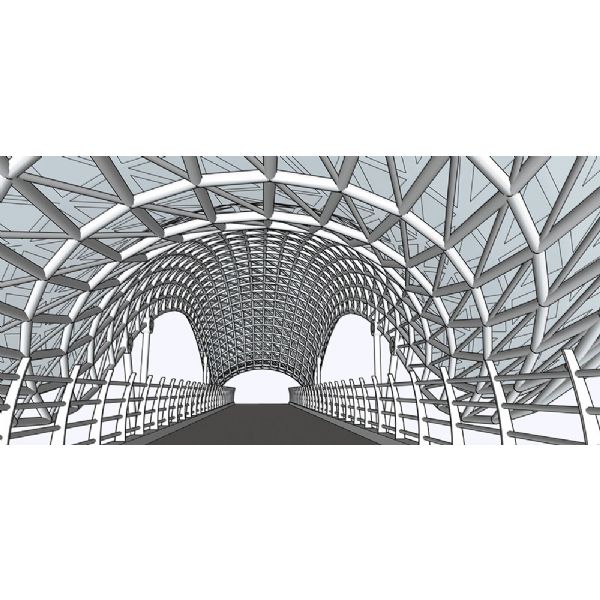

- Flexible Design with Elegant Aesthetics: One of the most distinctive features of the Steel Structure Corridor is its high design flexibility. With the aid of modern steel fabrication and modeling technologies, corridors can be constructed in a variety of complex forms—straight, curved, folded, cable-stayed, arched, or hyperbolic—fully integrating with diverse architectural styles and landscape requirements. Structural nodes can be flexibly arranged to accommodate different heights, angles, and positions, allowing for true site-specific, integrated design. Visually, steel structures offer clean lines and a modern texture. When combined with materials such as glass, aluminum panels, or grilles, they achieve a transparent and lightweight visual effect, enhancing both the identity of the corridor and the visual coherence of the entire architectural complex. Beyond functionality, the corridor can serve as an architectural landscape feature, enhancing spatial quality and aesthetic value—becoming a perfect fusion of function and artistic expression in urban design.

- Efficient Construction and Convenient Assembly: Steel Structure Corridors are typically designed with modular systems, where all components can be precisely prefabricated in the factory, ensuring better quality control and dimensional accuracy. On-site work involves mainly lifting and joint connections, resulting in a highly efficient assembly process that significantly shortens construction time. This is especially advantageous in high-traffic environments such as hospitals, commercial complexes, and schools, where prolonged construction is not feasible. Additionally, the construction process involves minimal wet work, reduced noise, and low dust levels, minimizing impact on the surrounding environment and enhancing safety. For complex scenarios such as high-altitude or over-road installations, steel structures can be hoisted in segments and positioned quickly, avoiding long-term traffic disruptions or operational suspensions. The entire construction process is highly standardized, facilitating strict quality control and project scheduling, greatly improving implementation efficiency and delivery quality—meeting modern urban demands for green and rapid construction.

- Superior Performance and Reliable Safety: Steel Structure Corridors demonstrate excellent mechanical performance and durability, especially in terms of seismic resistance and safety. Steel possesses inherent toughness and ductility, making it resistant to sudden fracture under extreme loads such as earthquakes, while absorbing large amounts of energy to improve seismic performance. Steel structures are also less prone to cracking or deformation, ensuring long-term stability. Corridors can be specifically designed to withstand regional wind loads, snow loads, and temperature fluctuations, ensuring structural safety and reliability. Corrosion resistance can be greatly enhanced through protective coatings or hot-dip galvanizing, making the structure suitable for coastal, humid, or industrial environments. In high-temperature or fire-prone conditions, fire-resistant coatings and fireproof wraps can be applied to further enhance fire safety. These features ensure safe pedestrian passage, secure operation, and stable building connectivity.

- Versatile Functions and Strong Adaptability: The Steel Structure Corridor goes beyond basic connectivity—it can integrate multiple composite functions tailored to specific project needs, making it a highly efficient tool for modern architectural space integration. Functionally, the corridor can serve as a pedestrian walkway, utility bridge, emergency escape route, or scenic viewing platform. It can be enclosed, semi-enclosed, or open, depending on climate conditions and usage requirements. Internally, it can be equipped with lighting, ventilation, surveillance, fire protection, and other systems to meet round-the-clock usage and high safety standards. Particularly in hospital campuses, school complexes, industrial parks, and integrated developments, Steel Structure Corridors effectively solve the problem of disjointed inter-building circulation, enhancing spatial synergy. Their exceptional adaptability allows them to meet diverse site and functional demands—serving both practical needs and elevating project quality and user experience—earning them widespread favor among architects and developers.

Product Parameters

| Material Standard: | AISI, ASTM, BS, DIN, GB, JIS | Steel: | Q235B (commonly used carbon structural steel, suitable for general construction use) | ||

| Q355B (commonly used carbon structural steel, suitable for general construction use) | |||||

| 45# (suitable for components with high strength requirements) | |||||

| 40Cr (alloy structural steel, suitable for parts bearing heavy loads) | |||||

| Country of origin: | China | Certification: | CE (European Union Standard) | ||

| GB (Chinese National Standard) | |||||

| ISO9001 (International Quality Management System Certification) | |||||

| AWS (American Welding Society Certification) | |||||

| Surface treatment: | Primer/Intermediate/Topcoat (color and coating thickness can be customized according to customer needs) | Material Thickness Tolerance: | ±0.5 | ||

| Hot-dip galvanizing (superior corrosion resistance, suitable for harsh environments) | |||||

| Service scope: | Prefabricated Buildings | Wall & Roof Panels: | Steel plate/FRP plate (customized by customers) | ||

| Life: | 50 years | Paint coating: | Provide a variety of colors and coatings according to design requirements. | ||

| Wind resistance: | 12 levels | Shock resistance: | 8 levels | ||

| Quantity (square meters) | 1 – 2000 | 2001 – 5000 | 5001 – 10000 | >10000 | |

| Estimated time (days) | 26 | 35 | 43 | To be negotiated | |

| Service scope: | Design consultation, node deepening, construction plan, installation guidance | ||||

| Pricing method: | One price, no price increase in the middle, transparent price, a nd avoid hidden fees. | ||||

Technical Specifications

To ensure that we can provide a more accurate quotation and preliminary design, we recommend that you provide the following as much information as possible:

- Building appearance: shape, size, and height

- Material standards: Conform to ISO/ASTM/CE/GB standard certification for materials. Steel generally uses Q235B and Q355B. Special customization is available upon request.

- Building use: such as industrial plants, warehouses, offices, etc., so that we can reasonably recommend roofing and wall materials

- Load requirements: including live load, snow load, wind load, etc. If there are specific design standards or special usage requirements, please indicate them in advance.

- Coating standards: Through the coating standard certification in ISO/ASTM/CE/GB, we have stringent requirements on the protective performance and environmental adaptability of the coating, the compatibility of the coating, and the adhesion durability.

- Delivery Standard: Complying with the standard certification of products in ISO/AWS D1.1/CE/GB, we always provide customers with high-quality services.

If the above data cannot be provided temporarily, it is not a concern. We will make a preliminary plan for you based on the conventional parameters and further optimize the design in subsequent communication.

Quote Information

Support customized design, welcome to provide drawings for quotation.

Whether you have drawings or not, we welcome cooperation and can provide you with a professional quotation within 1 working day.

Existing drawings

Please send us your design drawings, and we can provide one-stop service from processing and production, logistics, and delivery to installation guidance. With advanced production technology, complete testing equipment, and a complete technical system, we always provide customers with high-quality and competitive steel structure products.

No drawings yet

Our design team is experienced and can customize light steel structure buildings according to your needs, including but not limited to gymnasiums, warehouses, workshops, industrial park buildings, halls, and dome building systems.

Professional design team to meet diverse needs

At the core of every successful steel structure project is a professional and experienced design team capable of transforming client requirements into practical, efficient, and durable solutions. Our company prides itself on maintaining a high-level team of architects, structural engineers, and technical consultants who specialize in tailoring steel structure systems to meet the specific needs of different industries and applications.

Whether the project involves an airport terminal, warehouse facility, high-rise hotel, railway structure, or manufacturing plant, our design experts are equipped with the knowledge and tools to deliver optimized structural layouts. Every project is unique, and we recognize that a one-size-fits-all approach is not sufficient in the modern construction industry. Instead, we provide customized solutions that balance structural integrity, cost-effectiveness, and architectural aesthetics.

To ensure the most accurate quotations and design proposals, we encourage clients to share as much detailed information as possible during the early stages of consultation. This includes:

- Building purpose – whether the structure is intended for logistics, storage, hospitality, aviation, commercial use, or industrial production.

- Size and dimensions – covering total area, span, height, and layout preferences to determine the right type of steel structure system.

- Load requirements – including considerations for live loads, dead loads, wind loads, and seismic performance to guarantee safety and durability.

- Local standards and codes – compliance with national or regional construction regulations to ensure the project meets all legal and safety requirements.

- Special features – such as insulation needs, energy-saving technologies, interior flexibility, or future expansion requirements.

By gathering this information, our design team can create a precise and well-calculated structural plan that minimizes unnecessary costs, maximizes efficiency, and shortens construction timelines. Clients benefit not only from tailored engineering solutions but also from our commitment to innovation and sustainability, which ensures the final building remains reliable and adaptable for decades to come.

Ultimately, our goal is to deliver more than just steel structures—we deliver trustworthy partnerships built on expertise, transparency, and dedication to client success. With a professional design team that understands the complexity of modern projects, we are able to transform diverse needs into landmark structures that stand the test of time.

Delivery site photos

|

|

| Delivery of Steel Structure Components (Container Packing) | Delivery of Steel Structure in Sections (Loose Parts) |

|

|

| Delivery of Steel Structure Combinations (Mixed Method) | Delivery of Steel Structure Modular Products (Assembled and Packaged in Units) |

Practical Application

Large Commercial Complexes

In large commercial complexes, Steel Structure Corridors are widely used to connect shopping malls, office buildings, hotels, apartments, and other diverse functional spaces, enabling efficient integration of multiple business types. These corridors serve not only as pedestrian passageways but also as viewing platforms and brand display spaces, enhancing the commercial atmosphere and customer experience. Their flexible design allows them to span city roads or inner courtyards, blending seamlessly into the architectural ensemble with a lightweight and transparent form, thereby increasing the overall commercial value. The advantage of rapid construction also makes them ideal for expansion projects carried out while the complex remains in operation, minimizing construction disturbances.

Urban Integrated Parks

In urban integrated parks such as technology parks, industrial zones, and administrative centers, Steel Structure Corridors are used to facilitate functional connectivity and integrate pedestrian systems between buildings, improving operational efficiency and convenience. These corridors provide all-weather access between office buildings, conference centers, and supporting facilities, avoiding disruptions caused by rain or snow. Their design can reflect the overall park style, creating a visually unified and iconic corridor system that not only serves practical functions but also enhances the overall quality and architectural identity of the park—becoming a key element in showcasing a modernized image.

Healthcare Facilities

In hospitals and medical complexes, Steel Structure Corridors serve as critical transportation links connecting emergency departments, inpatient wards, diagnostic centers, and administrative buildings. These corridors ensure the efficient, smooth, and safe transfer of patients, medical staff, and equipment—especially vital in emergency scenarios. Thanks to their lightweight structure and short construction cycle, they are well-suited for expansion or renovation projects without interrupting hospital operations same like special-shaped space truss structure. Enclosed corridors can also maintain controlled temperature and humidity, providing a clean environment for medical transport. Moreover, their aesthetically pleasing design brings warmth and human-centered care to the hospital environment.

University Campuses

University campuses often span large areas with dispersed buildings. Steel Structure Corridors are commonly used to connect teaching buildings, laboratories, libraries, and dormitories, forming an efficient pedestrian network. These corridors enable students and faculty to move quickly between facilities, improving educational efficiency. They can also serve as semi-public spaces for interaction, reading, or rest. The flexible structural forms can integrate with the campus’s architectural style, enhancing its aesthetic appeal. Modular design makes future adjustments or expansions easy, meeting the long-term, evolving needs of campus development.

Transportation Hubs

At railway stations, metro hubs, and intercity transit centers, Steel Structure Corridors are often used to connect terminals, waiting areas, platforms, and supporting facilities. Their high strength, durability, and fast construction make them especially suitable for high-traffic, high-density, and high-efficiency transportation environments. These corridors are typically enclosed or semi-enclosed to ensure all-weather accessibility and are designed with interfaces for crowd guidance systems, security checkpoints, and information displays. By optimizing pedestrian flow, they improve the passenger experience and enhance the operational efficiency of the entire station area.

Airport Terminals

Between airport terminals and auxiliary buildings, Steel Structure Corridors are frequently employed to link terminals, parking structures, VIP areas, and office buildings, forming an integrated and convenient airport environment. Structurally, they enable ultra-long spans and lightweight construction, reducing foundation loads while preserving open sightlines to enhance passenger comfort. The interior of these corridors can be equipped with moving walkways, lighting, and guidance systems to improve operational efficiency. Their elegant and fluid appearance also supports the international image of the airport, making them a core visual element of the terminal landscape.